High-speed train rolling bearing fault diagnosis method

A rolling bearing and fault diagnosis technology, applied in mechanical bearing testing, measuring devices, instruments, etc., can solve the problems of slow model speed, low fault identification accuracy, etc., to improve accuracy, real-time performance, performance and driving safety guarantee. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

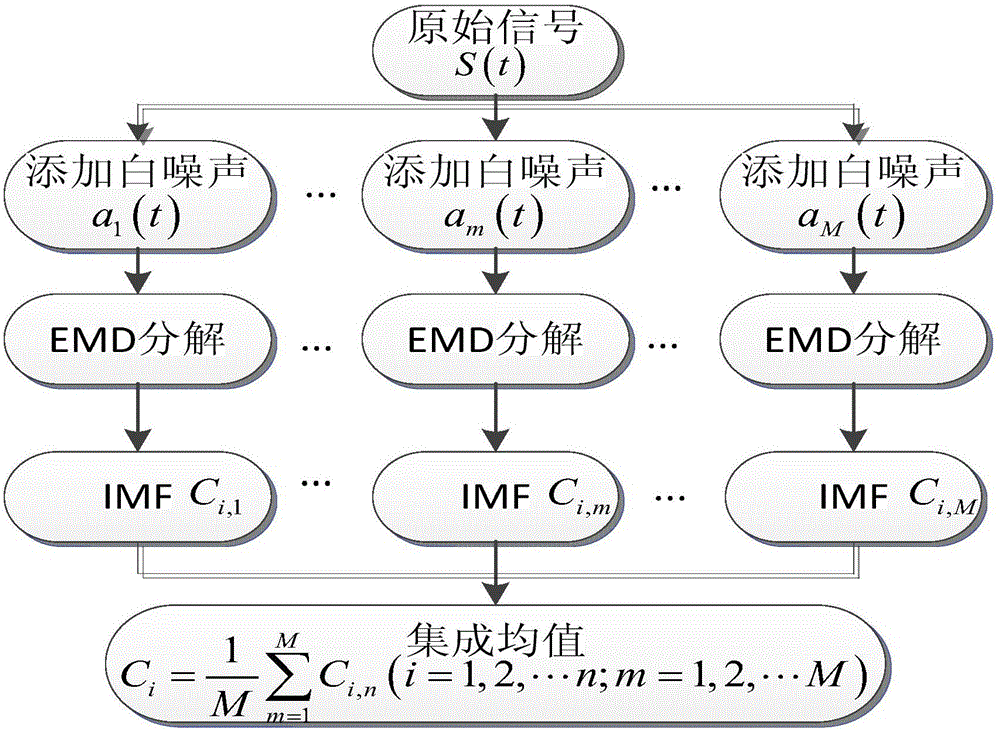

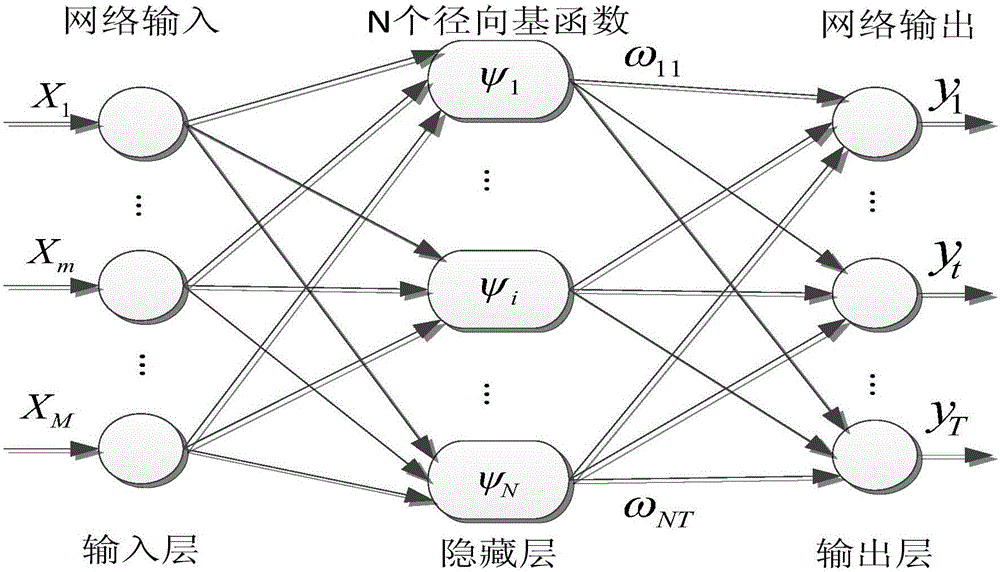

Method used

Image

Examples

Embodiment 1

[0060]Embodiment 1 This embodiment is completed in Matlab R2010a software.

[0061] A high-speed train rolling bearing fault diagnosis method, comprising the following steps:

[0062] I. Establishment of fault diagnosis model

[0063] Step 1: Divide the bearings into four state types: normal bearings, rolling element fault bearings, outer ring fault bearings, and inner ring fault bearings.

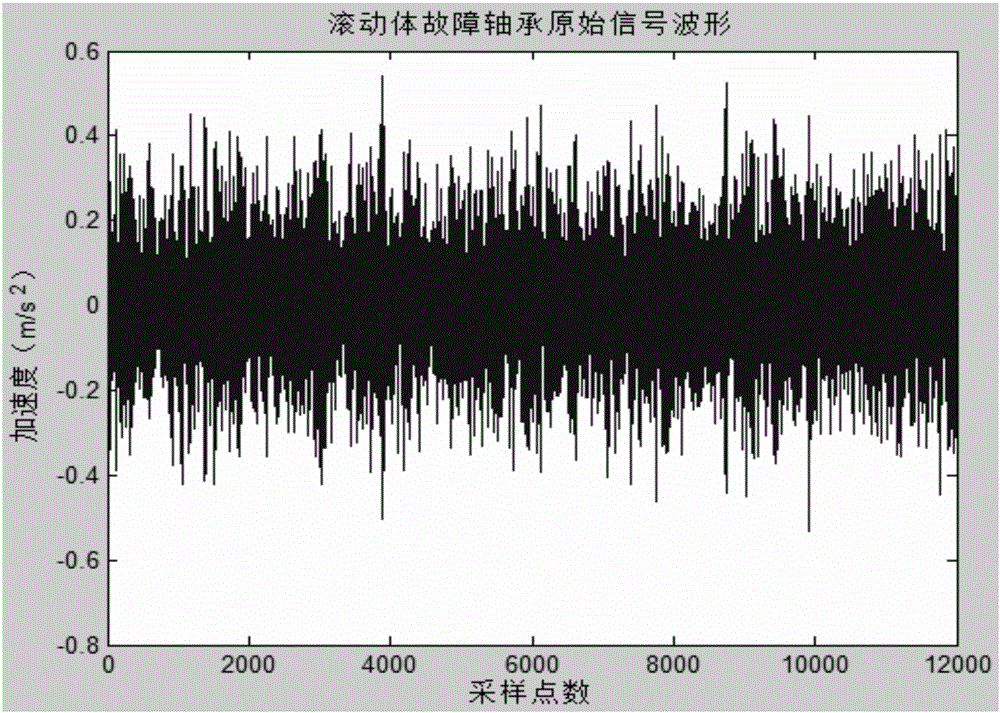

[0064] The specific method of this embodiment is as follows: First, the rolling element faults, outer ring faults and inner ring faults are arranged on the rolling bearing by using electric discharge machining technology. Under the working conditions, the acceleration sensor is used to collect the vibration signal, which is collected by the 16-channel DAT recorder. A total of 40 sets of data are used, that is, normal bearings, bearings with rolling element faults, bearings with outer ring faults, and bearings with inner ring faults, each with 10 sets. Taking the data of rolling element f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com