Large-aperture ultra-smooth surface defect detection device and method

An ultra-smooth surface and detection device technology, which is used in measurement devices, optical testing of flaws/defects, and material analysis by optical means. , large-caliber optical components and heavy weight, etc., to achieve the effects of reliable detection results, shortening detection time, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

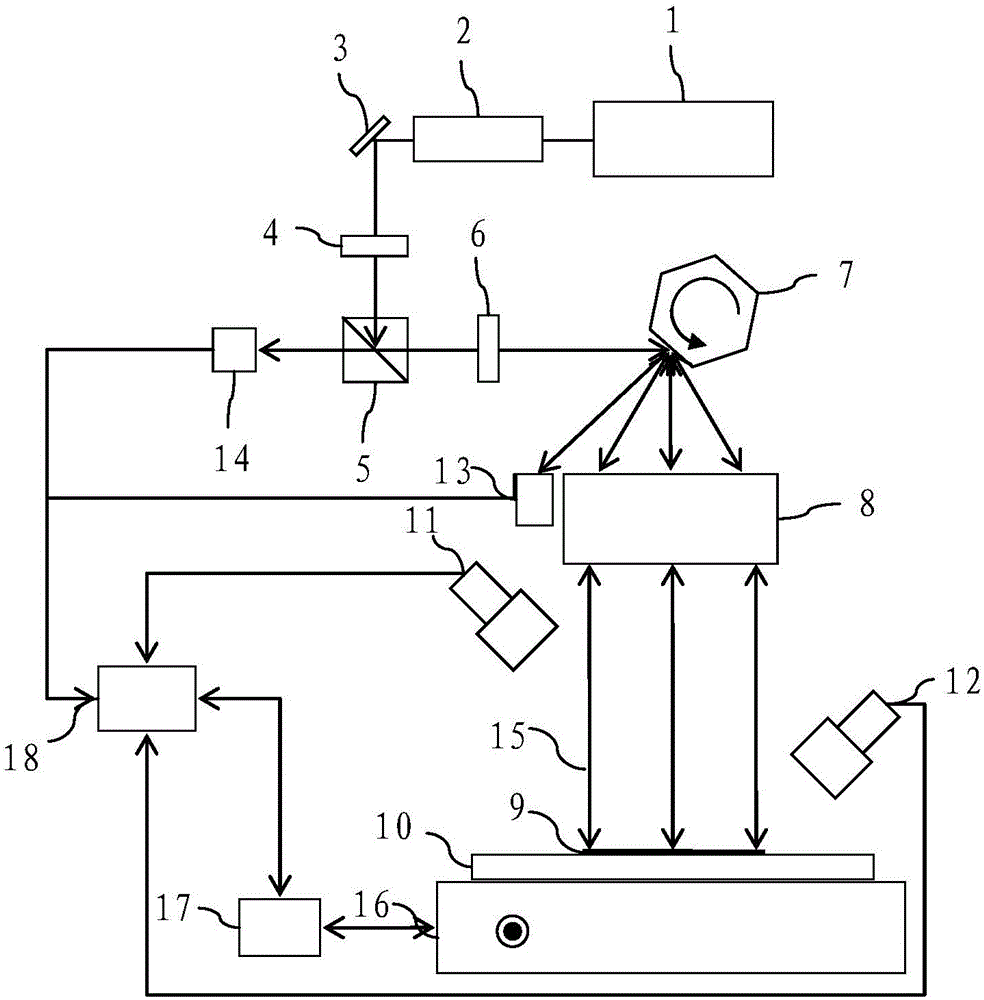

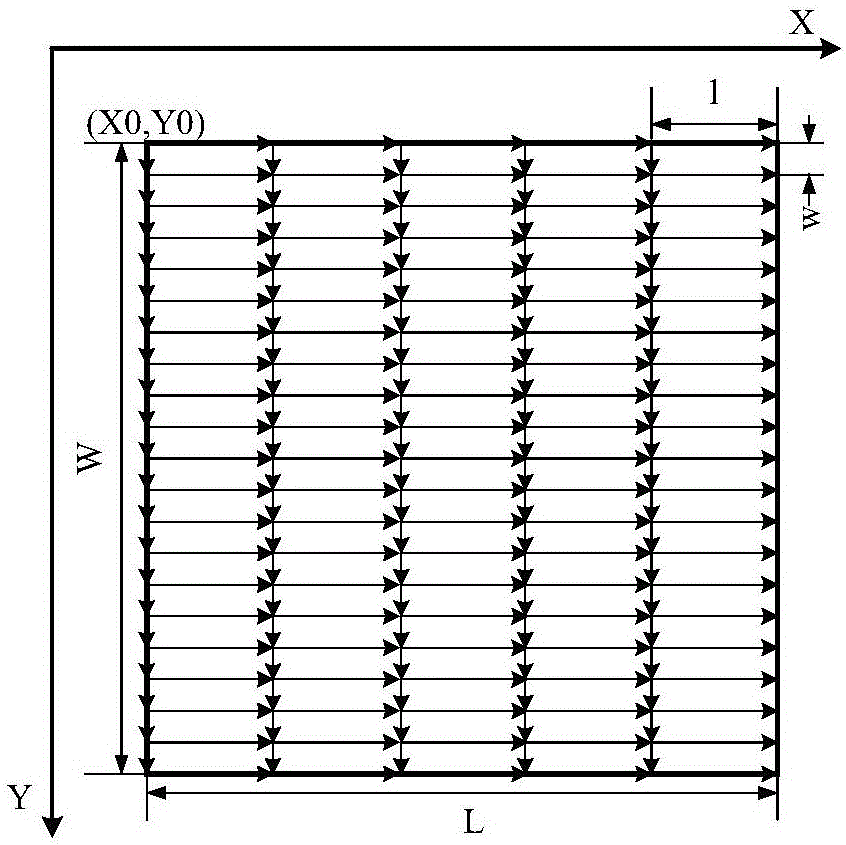

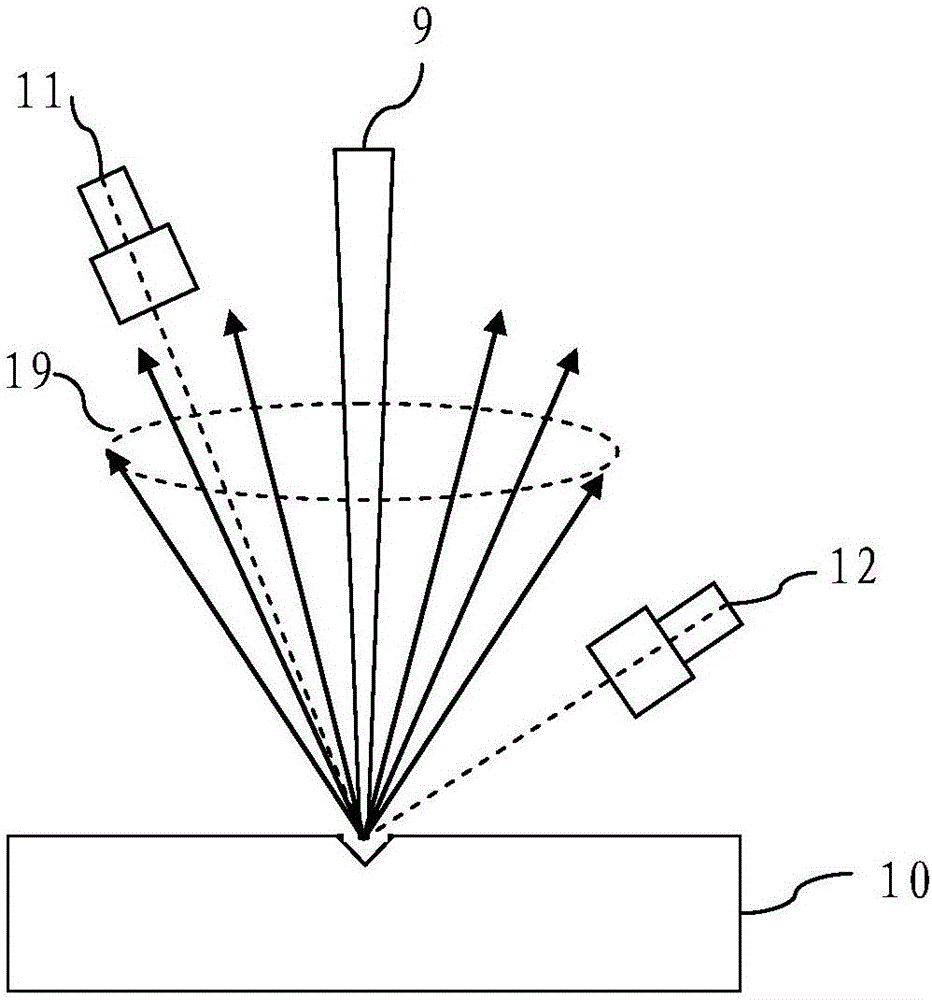

[0041] Such as figure 1 As shown, the measurement is that the computer 18 controls the precision displacement platform drive circuit 17, so that the precision displacement platform 16 drives the sample 10 to be tested along the figure 2 Scanning is performed on the scanning route shown to realize the scanning of the entire surface of the sample 10 to be tested. The angle between the optical axis direction of the high-angle scattered light detector 11 and the surface normal of the sample 10 to be tested is less than 45°, and the angle between the optical axis direction of the low-angle scattered light detector 12 and the surface normal of the sample 10 to be tested is greater than 45° °. The reflected light detector monitors the reflective condition of the surface of the sample 10 to be tested in real time. The signals received by the high-angle scattered light detector 11, the low-angle scattered light detector 12, and the reflected light detector 14 are transmitted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com