Rotary type slow-baking safety test device

A test device and safety technology, applied in the direction of material explosion, can solve the problems of narrow temperature range, high heating efficiency, short time, etc., to achieve the effect of reducing test risk and cost, strong environmental adaptability, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

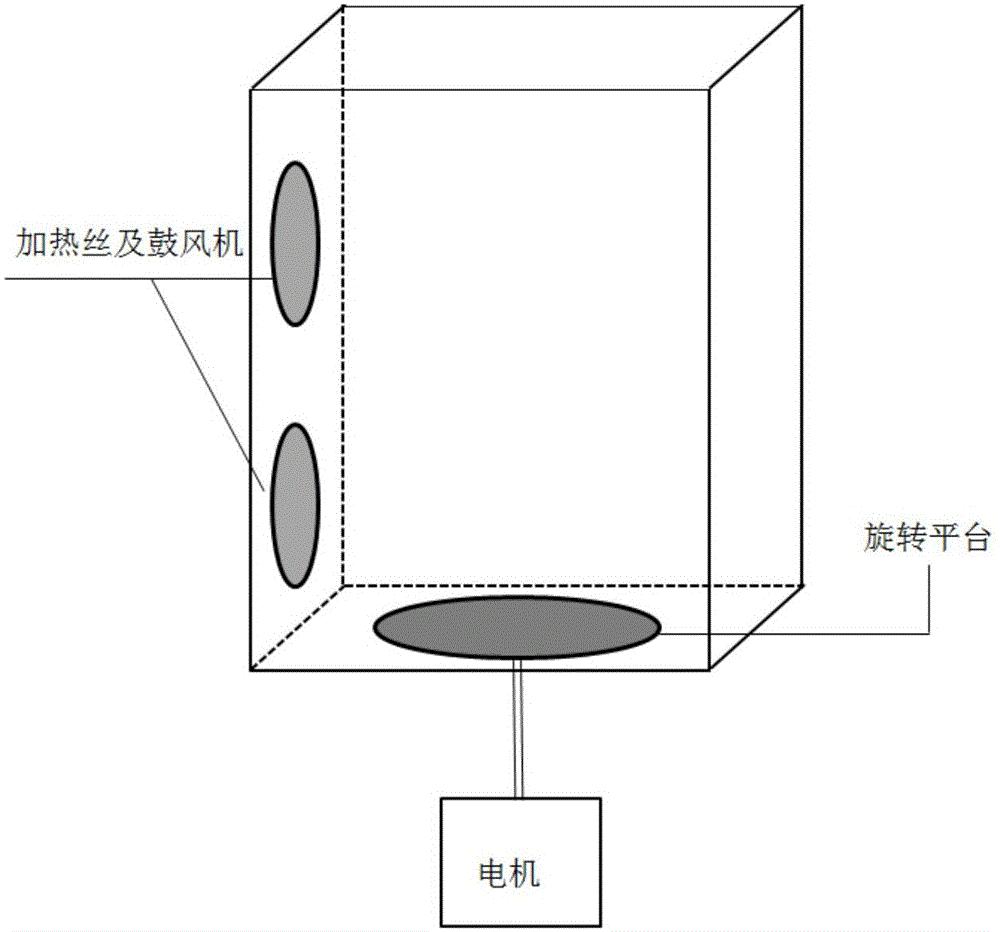

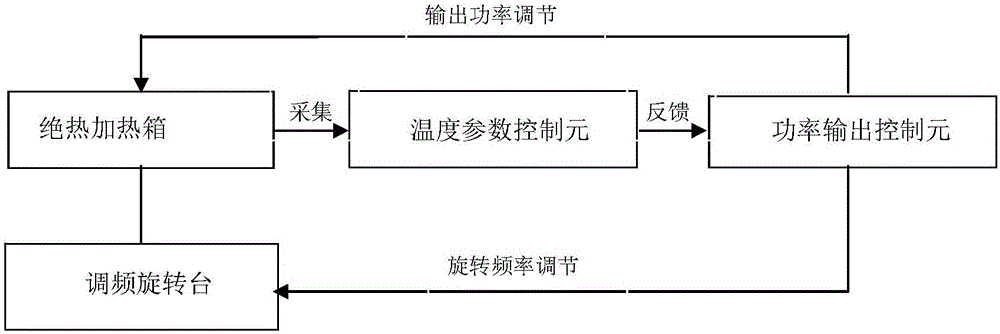

Method used

Image

Examples

Embodiment 1

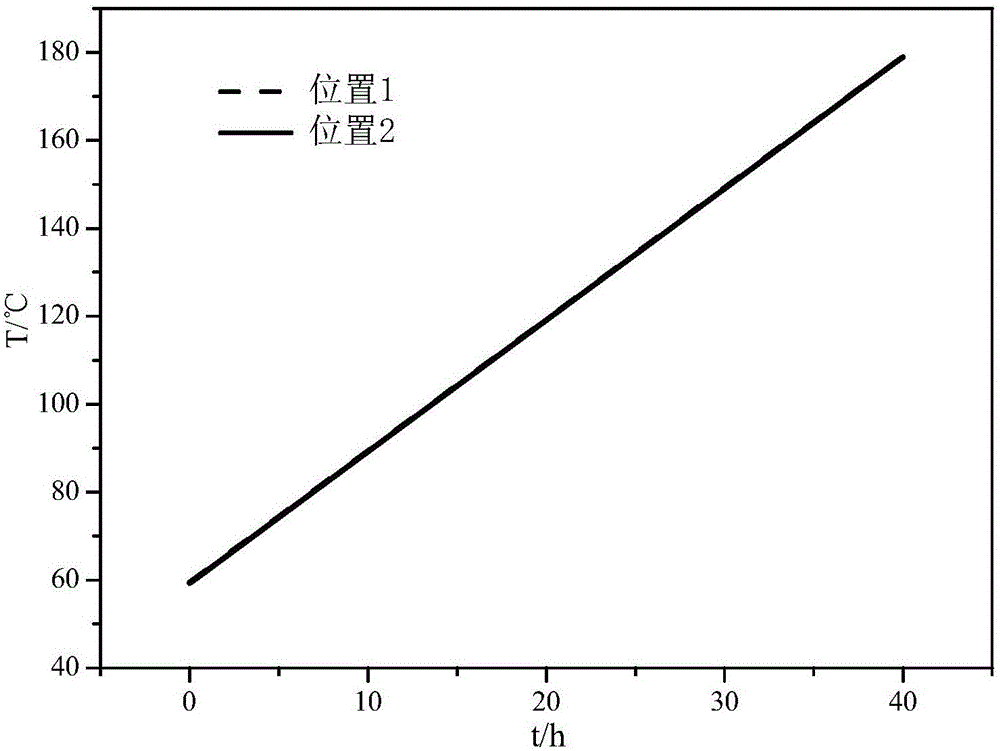

[0036] Embodiment 1: Using a K-type thermocouple, under the condition that the sampling frequency is 12 times / minute, the temperature rise rate calibration of the rotary slow-roasting safety test device is measured. The measured temperature rise curve is shown in image 3 .

Embodiment 2

[0037] Embodiment 2: Using a K-type thermocouple, under the condition that the sampling frequency is 12 times per minute, when the filling ratio of the simulated bomb of the measurement sample is 18%, the temperature rise curve of different positions inside the adiabatic box, the measured temperature rise curve See Figure 4 , the results are shown in Table 3.

Embodiment 3

[0038] Embodiment 3: Adopt K-type thermocouple, under the condition that the sampling frequency is 12 times / min, measure the temperature rise curve of different positions inside the heat-insulated box when the filling ratio of the simulated bomb of the measurement sample is 38%, the measured temperature rise curve See Figure 4 , the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com