Distributed PID (Proportion Integration Differentiation) predictive function control method for furnace box temperature of waste plastic cracking furnace

A technology for predicting function control and furnace temperature, applied in the field of automation, can solve problems such as high model requirements, poor steady-state performance, and difficulty in achieving control effects with DPFC methods, and achieve good control quality and improved degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] Take the furnace temperature control of waste plastic pyrolysis furnace as an example:

[0101] The furnace temperature control system of the waste plastic pyrolysis furnace is a typical coupling process with multiple variables and hysteresis, and the adjustment method adopts the opening of the combustion nozzle.

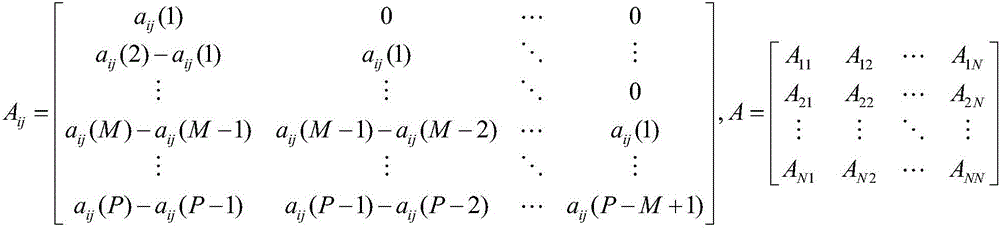

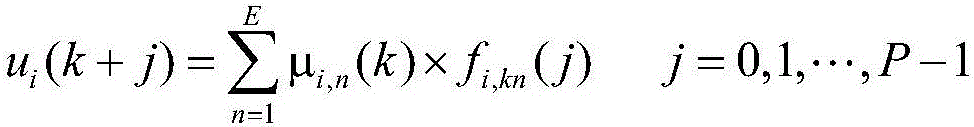

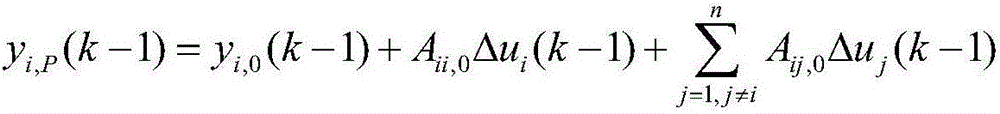

[0102] Step 1. Establish the step response model vector of the furnace temperature object through the real-time step response data of the waste plastics pyrolysis furnace furnace temperature control system. The specific method is:

[0103] 1.1 According to the idea of distributed control, a large-scale system with N input and N output is dispersed into N furnace subsystems;

[0104] 1.2 Under steady-state conditions, take the opening of the combustion nozzle of the j-th furnace as the input to conduct a step response experiment on the output temperature of the i-th furnace, and record the j-th (1≤j≤N) input and the i-th input respectively. (1≤i≤N) output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com