Distributed PID type dynamic matrix control method for furnace pressure of coke furnace

A dynamic matrix control and dynamic matrix technology, applied in the field of automation, can solve the problems that the DDMC method is difficult to achieve the control effect, the sampling period should not be too small, and the amount of online calculation is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Take coke oven furnace pressure control as an example:

[0090] The coke oven furnace pressure control system is a typical multi-variable coupling process, and the adjustment means is to control the valve opening of the flue baffle.

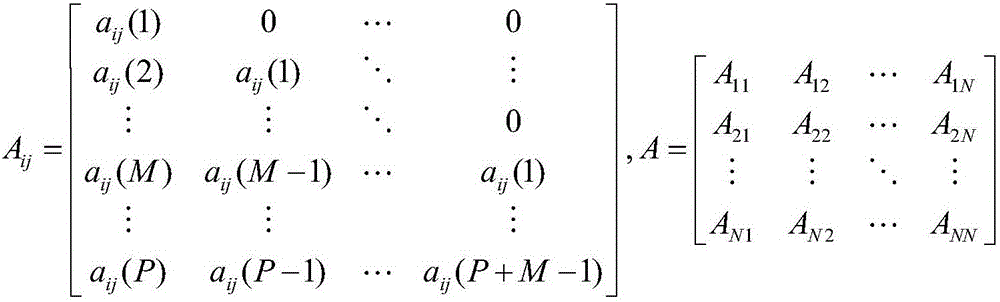

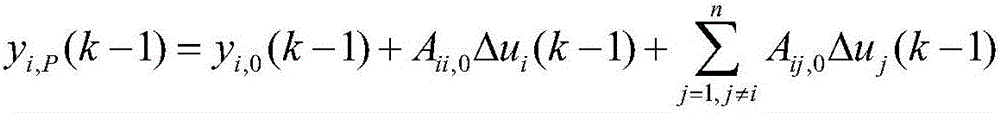

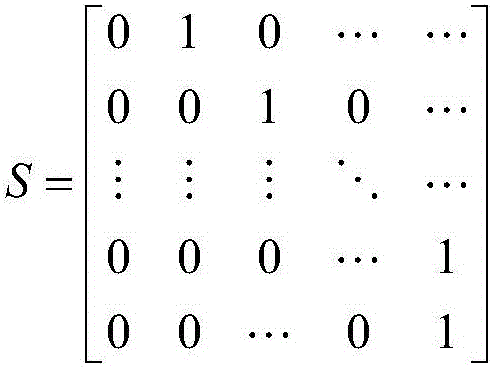

[0091] Step 1. Establish the step response model vector of the dynamic matrix control of the controlled object through the real-time step response data of the coke oven furnace pressure object. The specific method is:

[0092] 1.1 According to the idea of distributed control, a large-scale system with N input and N output is dispersed into N furnace subsystems;

[0093] 1.2 Under steady-state conditions, take the j-th furnace control quantity as the input to conduct a step response experiment on the i-th furnace output, and record the j-th (1≤j≤N) input and the i-th (1≤i ≤N) output step response curves;

[0094] 1.3 Filter the step response curve obtained in step 1.2, and then fit it into a smooth curve, record the step response data cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com