Current pulse-typed constant current source with ultrahigh speed

A pulsed, constant current source technology, applied in the field of power supply, can solve the problems of slow rising edge of pulse and low output current of pulse constant current source, and achieve the effect of stable function and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

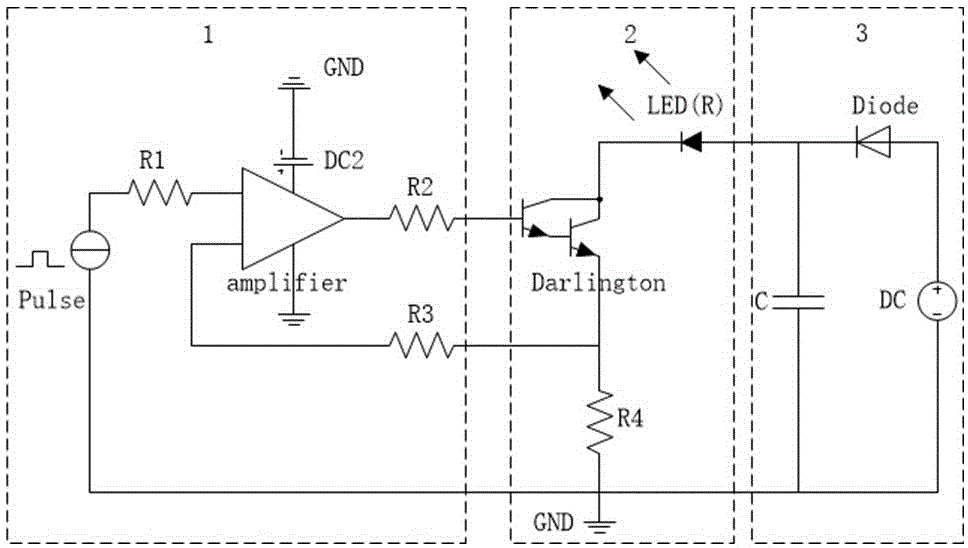

[0016] Such as figure 1 As shown, the overall structure of the present invention is composed of three parts: a constant current source control circuit 1, which outputs a control voltage; a load constant current circuit 2, which outputs a constant current pulse of a corresponding multiple of the control voltage; a capacitor charging and discharging circuit 3, which uses capacitor charging and discharging to make The rising edge of the constant current pulse is faster.

[0017] The concrete structure of the present invention is: constant current source control circuit 1, mainly by power operation amplifier OPA547, resistance R1, R2, R3, power supply DC2 and pulse signal source constitute; Load constant current circuit 2, mainly by Darlington tube QM400HA- H. Composed of sampling resistor group R4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com