Underwater disassembling repairing device and process of spent fuel assembly of pressurized water reactor

A pressurized water reactor and spent fuel technology, applied in the direction of reactor fuel elements, reactors, nuclear engineering, etc., can solve the problems of insufficient efficiency and safety, and achieve the effects of simple operation, cost saving, and radiation hazard reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

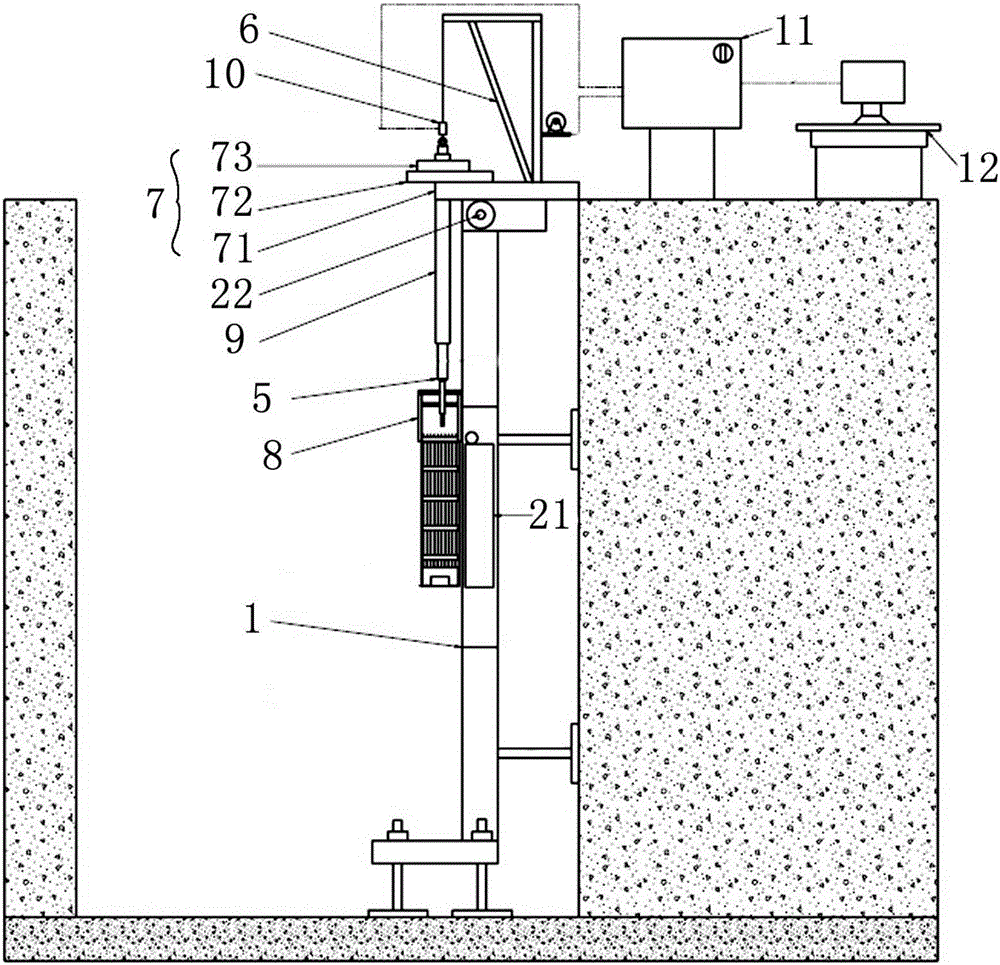

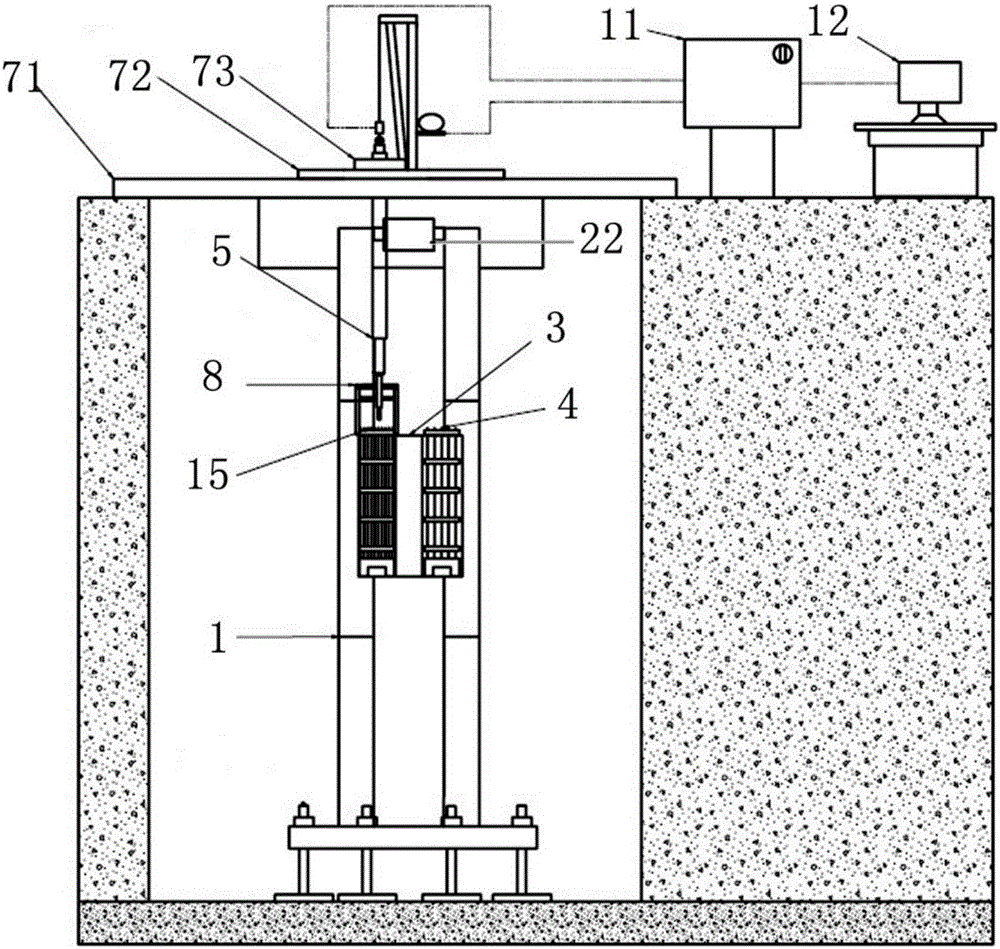

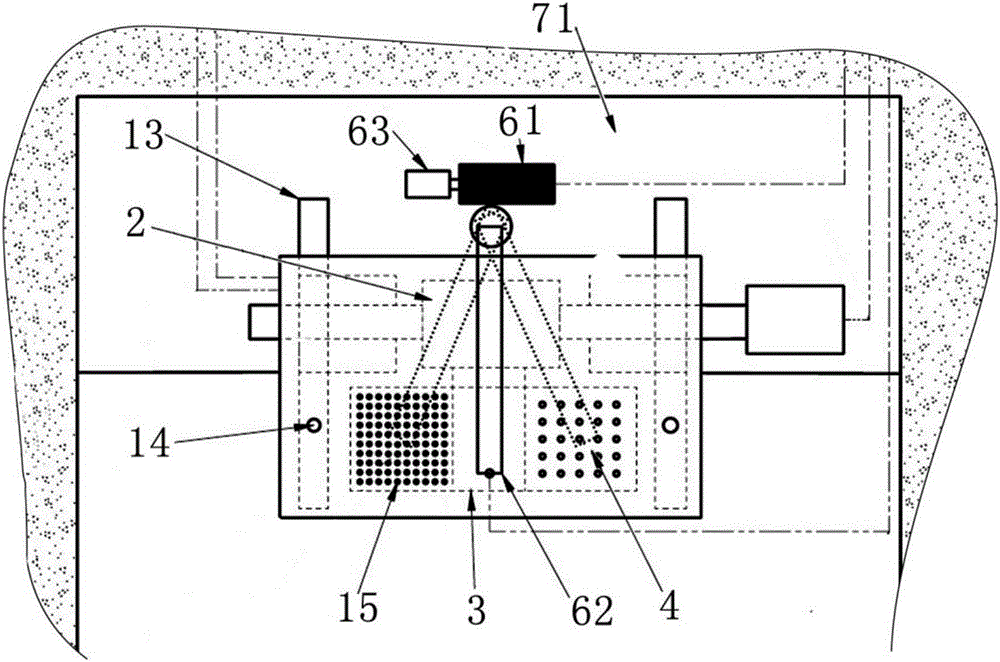

[0058] An underwater dismantling and repairing device for spent fuel assemblies of pressurized water reactors, such as figure 1 , figure 2 and image 3 shown, including:

[0059] Column track 1, a mobile trolley arranged on the column track 1, a component temporary storage device 3 and a fuel rod temporary storage device 4 arranged on the mobile trolley, and a rod pulling control platform arranged at the top of the column track 1;

[0060] The rod pulling control platform includes a fuel rod grabbing tool 5 for grabbing fuel rods, a rod pulling lifting platform 6 that controls the lifting of the fuel rod grabbing tool 5, and a rod pulling positioning platform that limits the horizontal position of the fuel rod grabbing tool 5 7.

[0061] The fuel rod grabbing tool 5 includes a cylinder 16, a spring 17, a transmission mechanism 18, an outer tube 19 and a gripping head. During work, when the air cylinder 16 is cut off, the spring 17 impels the transmission mechanism 18 to m...

Embodiment 2

[0078] The difference between this embodiment and Embodiment 1 is that in this embodiment, the structure at the position of the fuel rod grabbing tool 5 is optimized, so that the accuracy and accuracy are higher when grabbing, and the grabbing efficiency is effectively improved. The specific settings are as follows :

[0079] The present invention also includes a double-layer guide plate mechanism 8 arranged on the fuel assembly for precise positioning of the fuel rod grabbing tool 5 . A guide mechanism 9 is also provided on the rod pulling positioning platform 7, and the fuel rod grabbing tool 5 passes through the guide mechanism 9 and extends to a fuel rod grabbing position.

[0080] In the present invention, the double-layer guide plate mechanism 8 includes an E / F guide plate 23 and a clamping mechanism 24; wherein, holes are provided on the E / F guide plate 23, and the diameter of the holes is 1.7 times the distance between the fuel rods, and the holes are arranged diagonal...

Embodiment 3

[0085] The difference between this embodiment and Embodiment 2 is that a pulling force measuring instrument 10 is added in this embodiment to effectively monitor the pulling force of the fuel rod.

[0086] A pulling force measuring instrument 10 is also arranged at the connection between the rod pulling lifting platform 6 and the fuel rod grabbing tool 5, and the pulling force measuring instrument 10 is connected with the control box through a control line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com