Solar cell module and fabrication method thereof

A technology of solar cells and solar cells, applied in the field of solar modules, can solve the problems of increasing the cost of the system end, violations, etc., and achieve the effects of reducing the cost of LCOE, reducing the cost of cables and cables, and being easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

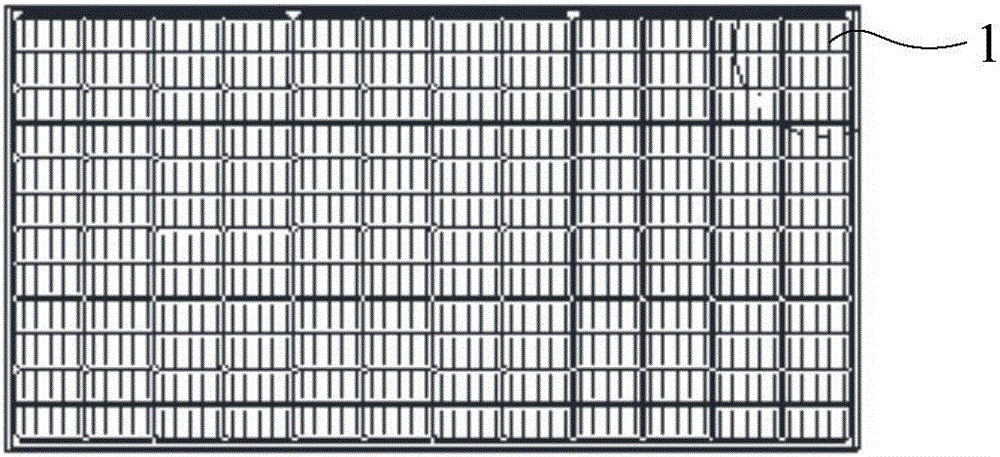

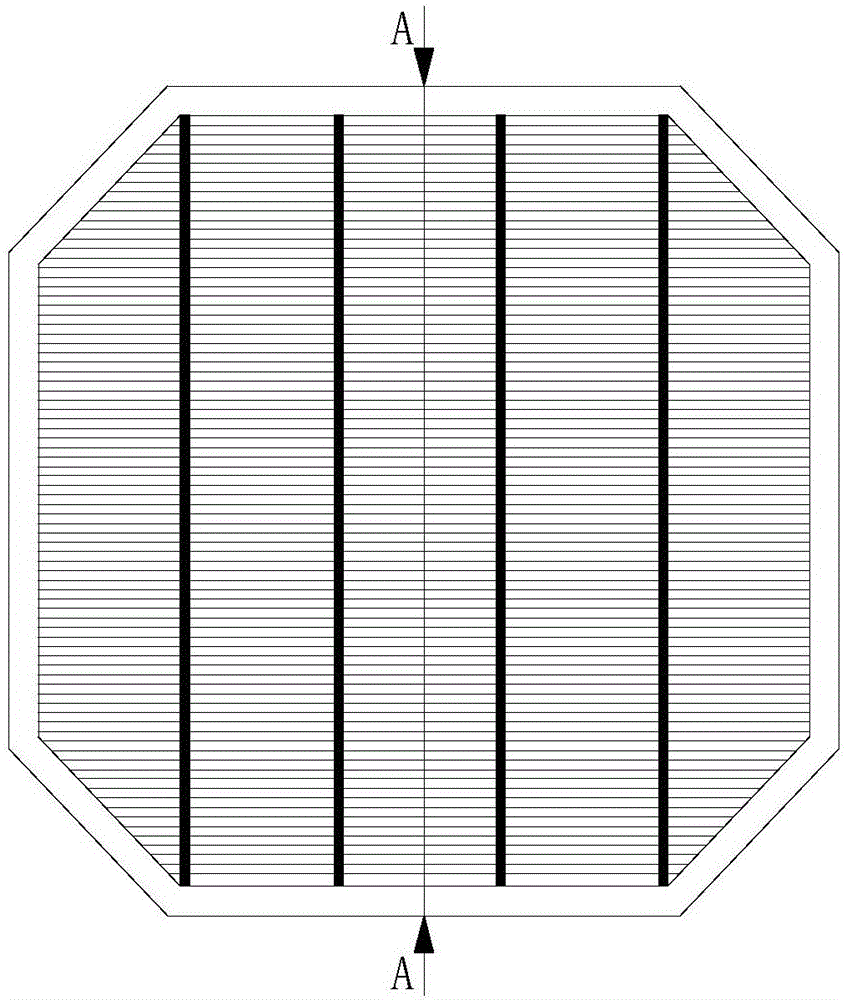

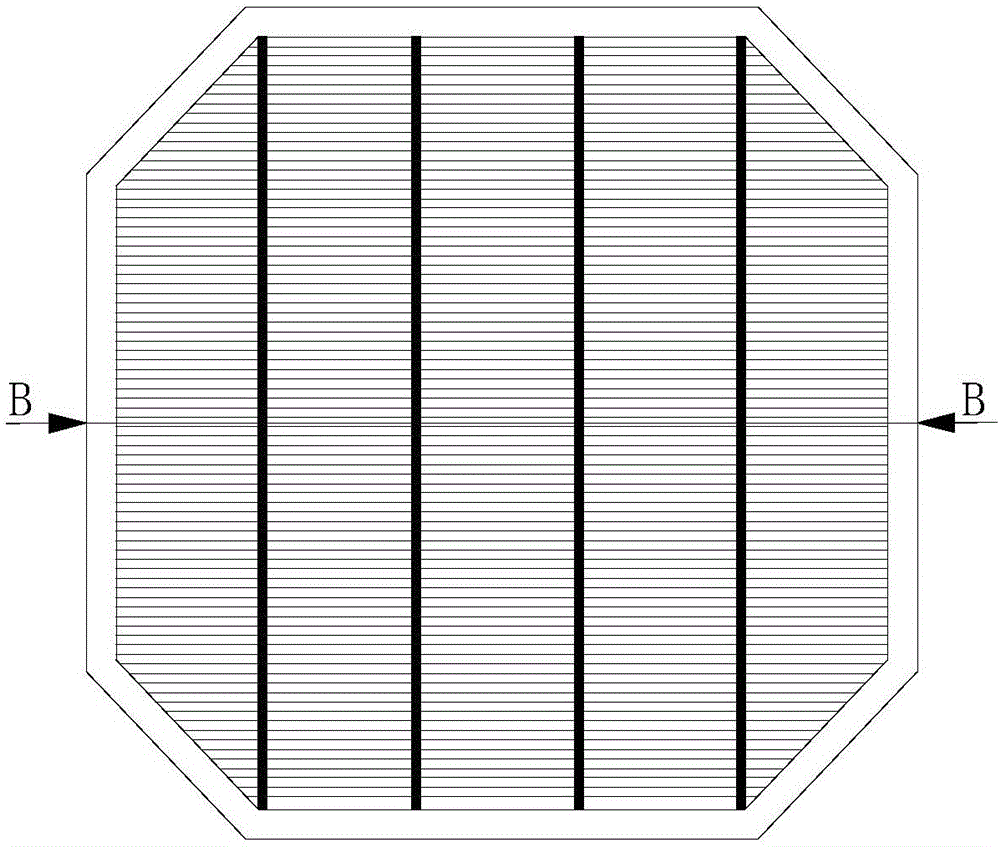

[0032] Attached below Figure 1-8 The technical solutions of the present invention are further described through specific implementation methods.

[0033] Such as figure 1 As shown, the present invention provides a solar cell assembly, including a plurality of solar cell strings, a plurality of solar cell strings are connected in parallel to form a solar cell string group, and each of the solar cell strings includes a sliced cell 1 or two The above sliced battery slices 1 connected in series, the sliced battery slices 1 are cut from a whole piece of solar battery slices, wherein, each of the solar battery slices is cut to form n sliced battery slices 1, and n≥2; Each of the solar cell strings is connected in parallel with m strings of the solar cell strings, and m>n.

[0034] In the present invention, the entire solar cell is divided into n equal parts, preferably, the planar shape of the divided sliced cell 1 is roughly rectangular, square, trapezoidal or triangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com