Cutting technology and device for LED white-light chips

A technology of cutting process and cutting device, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of affecting color temperature and light spots, cutting to chips, increasing labor costs, etc., achieving simple and reliable costs, ensuring consistency, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

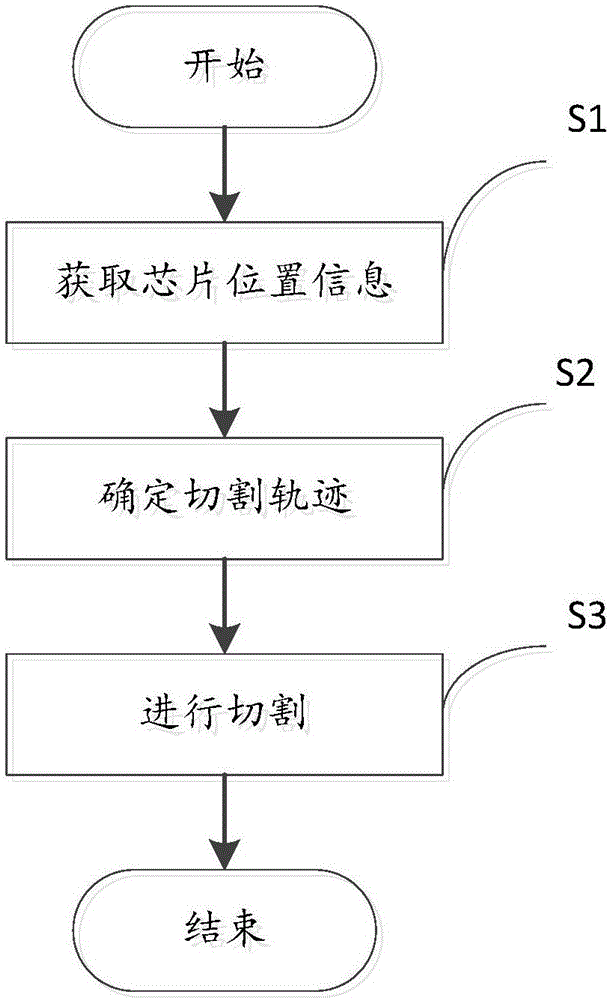

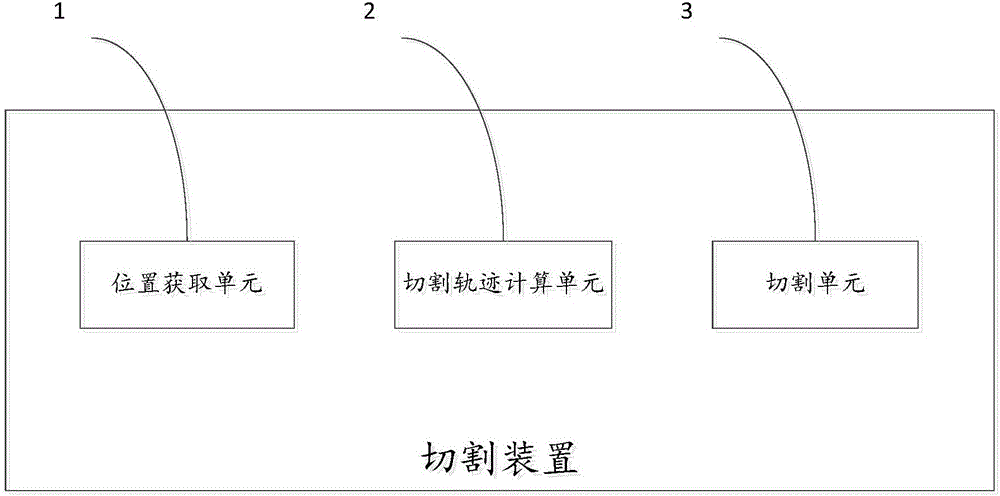

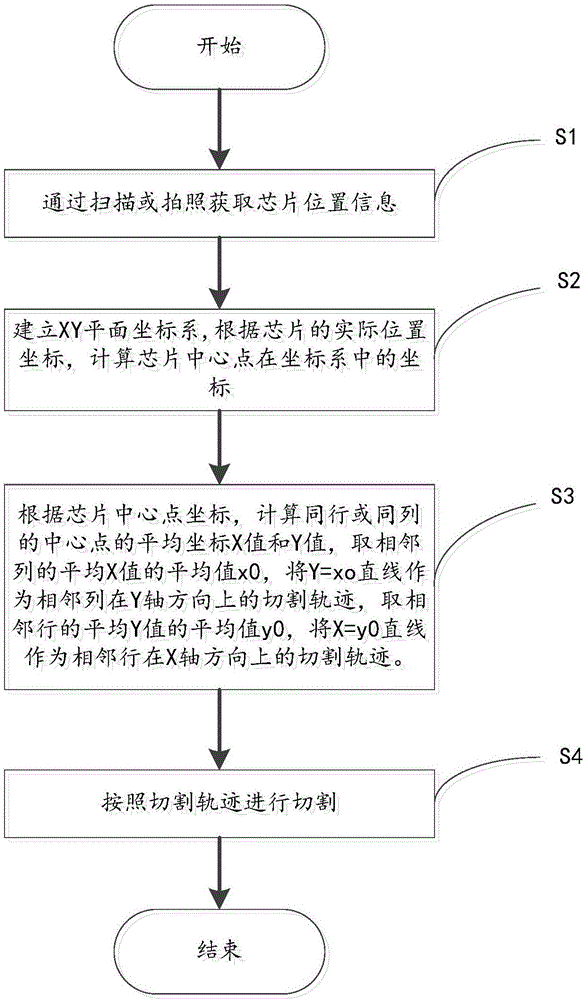

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0031] like Figure 5 As shown, one side of the chip 5 is in contact with the substrate, and the other five sides are covered with silica gel 6 , and fluorescent powder is uniformly mixed in the silica gel 6 . The usual array of chips 5 has a maximum size of 80mmx80mm square, the size of chips 5 usually ranges from 0.3 to 1.5mm, and the interval between rows and columns is about 0.5mm, so an array of chips 5 is about tens to hundreds of rows or columns.

[0032] The quality requirements of the white light chip 5 after cutting have two most important points: the color is consistent, and the chip 5 is in the center. The function of the phosphor is to turn the blue light of the chip 5 into white light, and the color of the white light depends entirely on the amount of the phosphor, and the color consistency means that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com