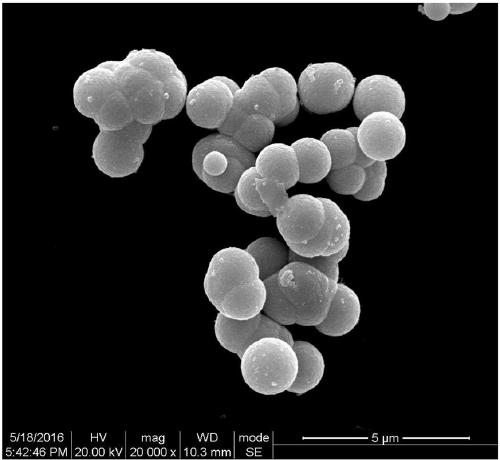

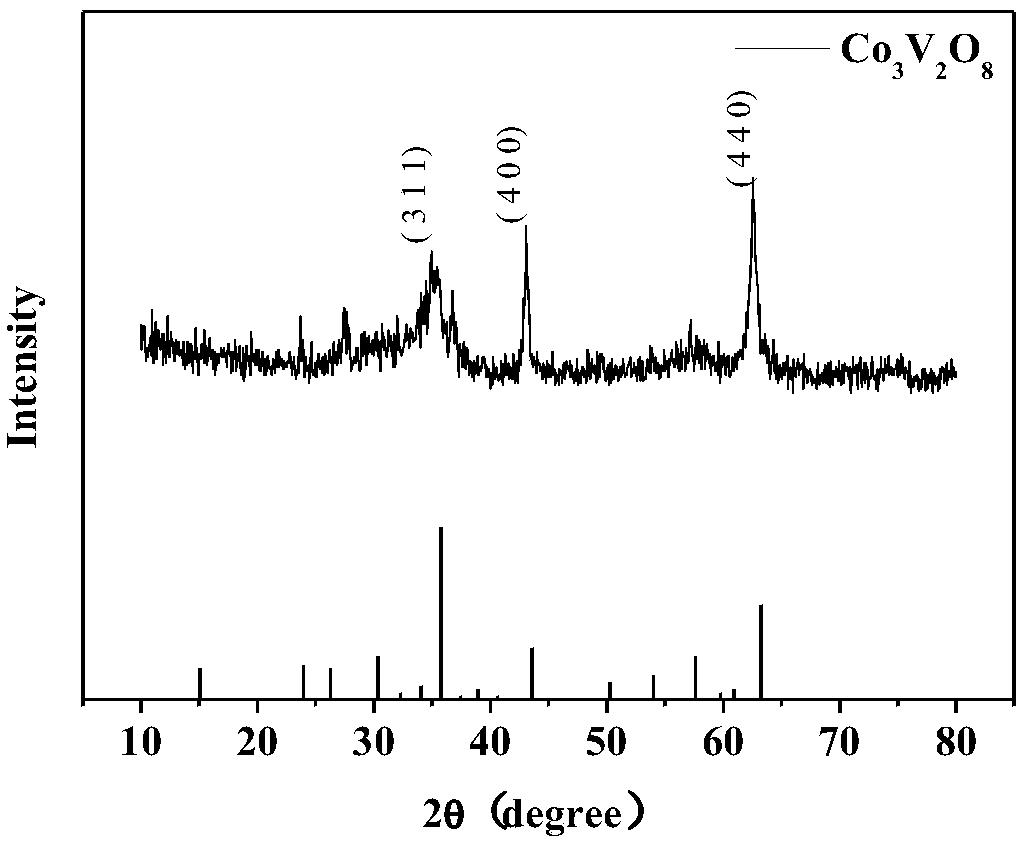

Spherical co3v2o8 and its preparation method

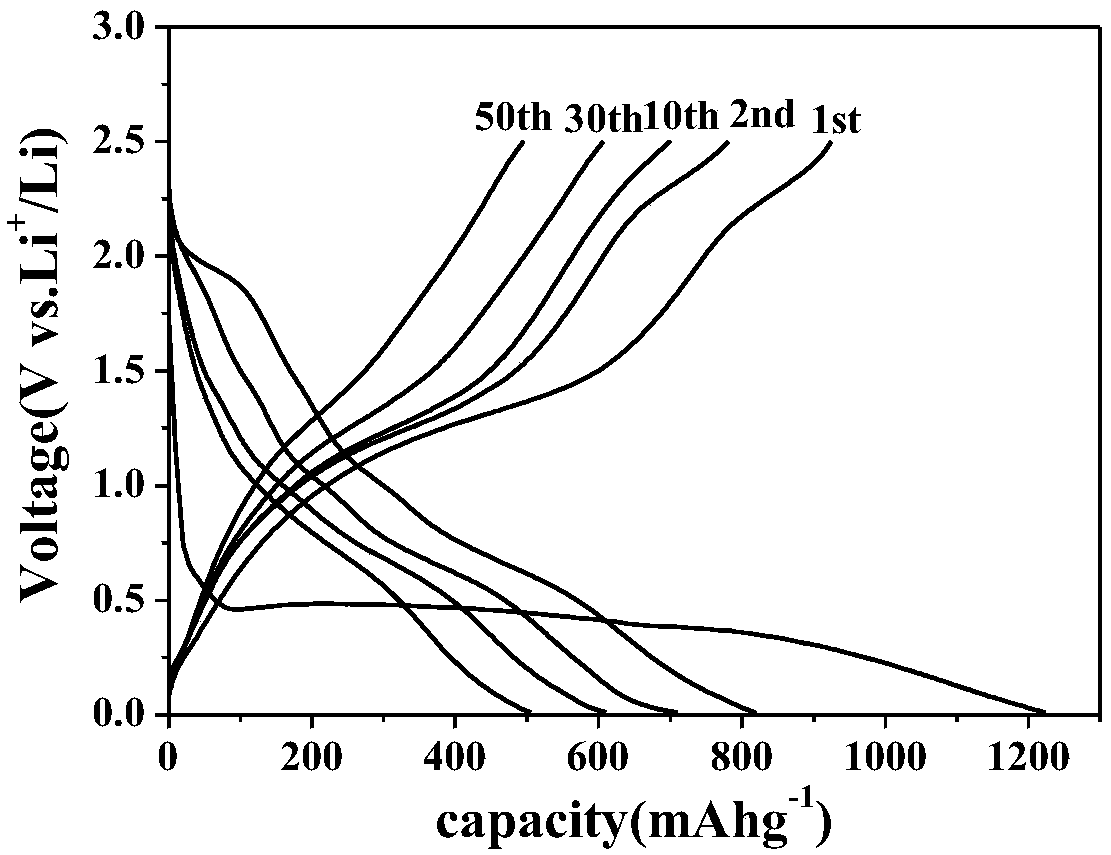

A spherical and solution technology, which is applied in chemical instruments and methods, cobalt compounds, structural parts, etc., can solve the problems of unprepared spherical Co, etc., and achieve uniform product particle size distribution, stable circulation effect, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A spherical Co 3 V 2 o 8 A preparation method comprising the steps of:

[0032] ① Add ammonium metavanadate to deionized water at 70°C, and keep stirring for 5 minutes, the solution turns into light yellow-green;

[0033] ②Add CO(NH 2 ) 2 , and continued to stir for about 5min until CO(NH 2 )2 Fully dissolved;

[0034] ③ CoCl 2 ·6H 2 O was added to the above solution, and continued to stir for 10 minutes until the solution turned into a transparent reddish brown, wherein the range of Co:V molar ratio was 1:3, CO(NH 2 ) 2 The concentration range of 0.036mol / L;

[0035] ④Transfer the solution prepared above into a hydrothermal reaction kettle, and react at a temperature of 160°C for a time range of 8 hours;

[0036] ⑤ Cool the reaction sample prepared above to room temperature, wash it several times with deionized water and absolute ethanol, dry it at 60°C for 4 hours, put it into a tube furnace, calcinate it to 250°C, keep it for more than 2 hours, and finally...

Embodiment 2

[0039] A spherical Co 3 V 2 o 8 A preparation method comprising the steps of:

[0040] ①Add ammonium metavanadate to deionized water at 80°C, and keep stirring for 10 minutes, the solution turns into light yellow-green;

[0041] ②Add CO(NH 2 ) 2 , and continued stirring for about 10min until CO(NH 2 ) 2 Fully dissolved;

[0042] ③Co(NO 3 ) 2 ·6H 2 O was added to the above solution, and continued to stir for 15 minutes until the solution turned into a transparent reddish brown, wherein the range of Co:V molar ratio was 1:5.5, CO(NH 2 ) 2 The concentration range of 0.078mol / L;

[0043] ④Transfer the solution prepared above into a hydrothermal reaction kettle, and react at a temperature of 220°C, and the time range is 24h;

[0044] ⑤ Cool the reaction sample prepared above to room temperature, wash it several times with deionized water and absolute ethanol, dry it at 90°C for 6 hours, then put it into a tube furnace, calcinate it to 350°C, keep it for more than 2 hou...

Embodiment 3

[0047] A spherical Co 3 V 2 o 8 A preparation method comprising the steps of:

[0048] ① Add ammonium metavanadate to deionized water at 75°C, and keep stirring for 7 minutes, the solution turns light yellow-green;

[0049] ②Add CO(NH 2 ) 2 , and continued stirring for about 7min until CO(NH 2 ) 2 Fully dissolved;

[0050] ③Co(Ac) 2 4H 2 O was added to the above solution, and continued to stir for 12 minutes until the solution became transparent reddish brown, wherein the range of Co:V molar ratio was 1:4, CO(NH 2 ) 2 The concentration range of 0.055mol / L;

[0051] ④Transfer the solution prepared above into a hydrothermal reaction kettle, and react at a temperature of 180°C, and the time range is 12h;

[0052] ⑤ Cool the reaction sample prepared above to room temperature, wash it several times with deionized water and absolute ethanol, dry it at 80°C for 6 hours, put it into a tube furnace, calcinate it to 350°C, keep it for 4 hours, and finally get Spherical Co ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com