Medical injection needle and manufacturing method therefor

A technology for injection needles and manufacturing methods, applied in the field of medical injection needles and their manufacturing, capable of solving problems such as thread scratches, processing difficulties, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

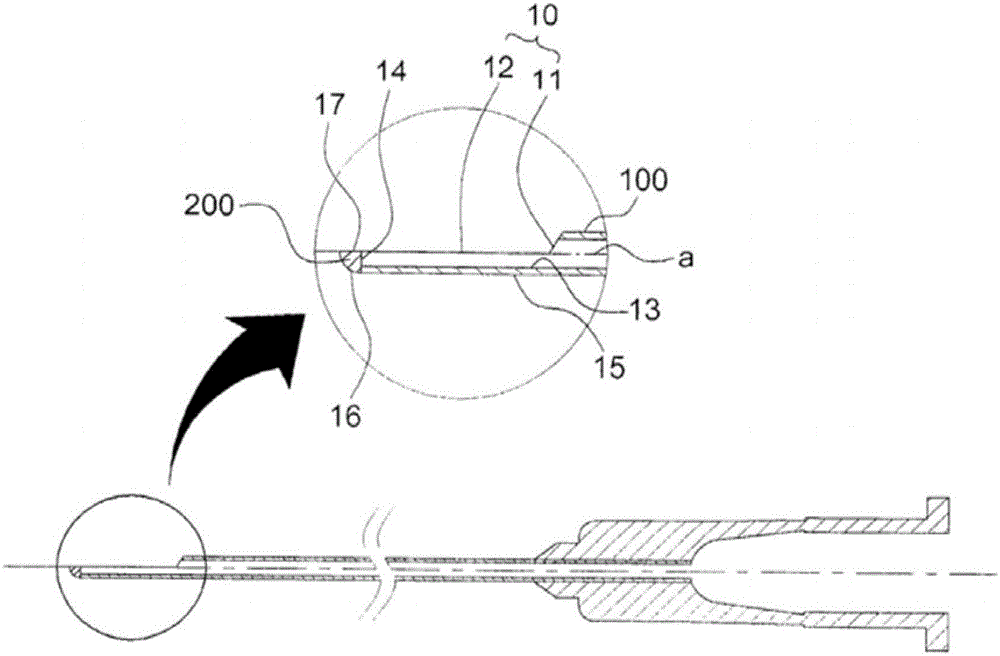

[0043] The manufacturing method of the medical injection needle of the present invention generally includes a rod body fixing step, a cutting step, a side cutting step, and a plane cutting step.

[0044] 1. Rod body fixing steps

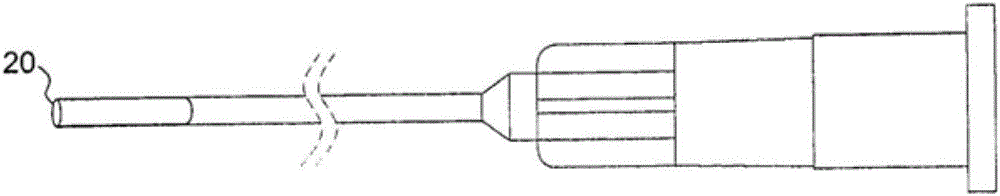

[0045] Such as Figure 7 As shown, in the rod body fixing step, the solid disc-shaped rod body 210 is integrally fixed on the top end of the hollow tube body 110 . At this time, preferably, the pipe body 110 and the rod body 210 are made of the same type of metal material, and the fixing method is preferably welding.

[0046] 2. Cutting step

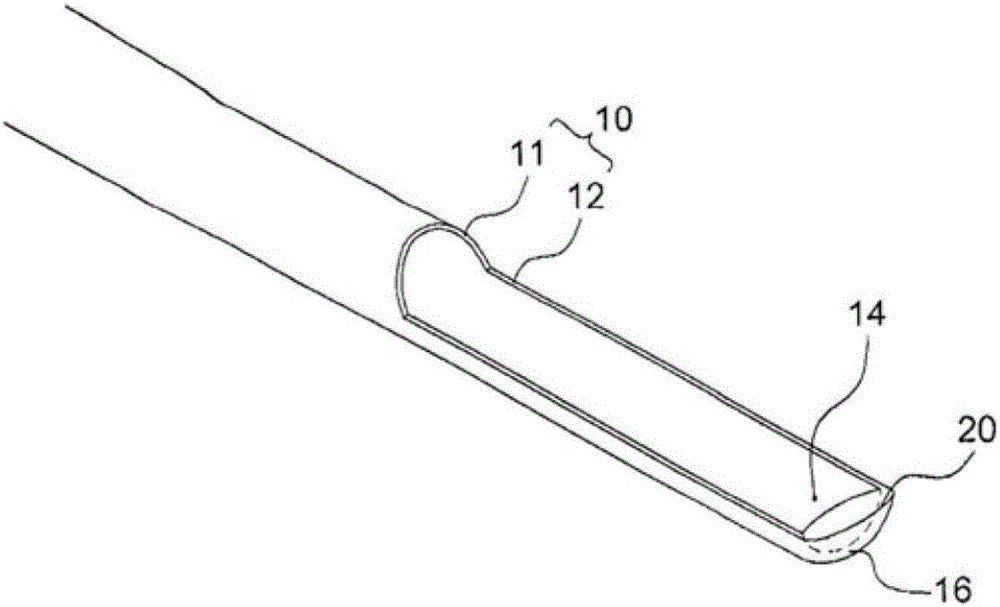

[0047] The cutting part 10 is formed by cutting from one side top surface of the pipe body 110 integrally fixed with the rod body 210 to a middle side of the rod body 210 . At this time, the cutting part 10 includes: an inclined part 11, which is formed to be inclined downward at a predetermined angle from the top end in a side view direction and the bottom end is located below the central axis a of the tubu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com