Air-cooled rotary disc and mill assembly for pulverizers

An air-cooled, rotating disk technology, applied in the field of rotating disk and disk mill components, pulverizers, can solve the problems of increasing heat generation, limiting productivity, ineffective guidance, and reducing cooling efficiency, etc., to achieve easy replacement and safety issues Reduce and avoid the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] A preferred embodiment of the invention and its advantages can be understood by referring to the accompanying drawings. In the drawings, the same reference numerals are used for like and corresponding parts of the drawings.

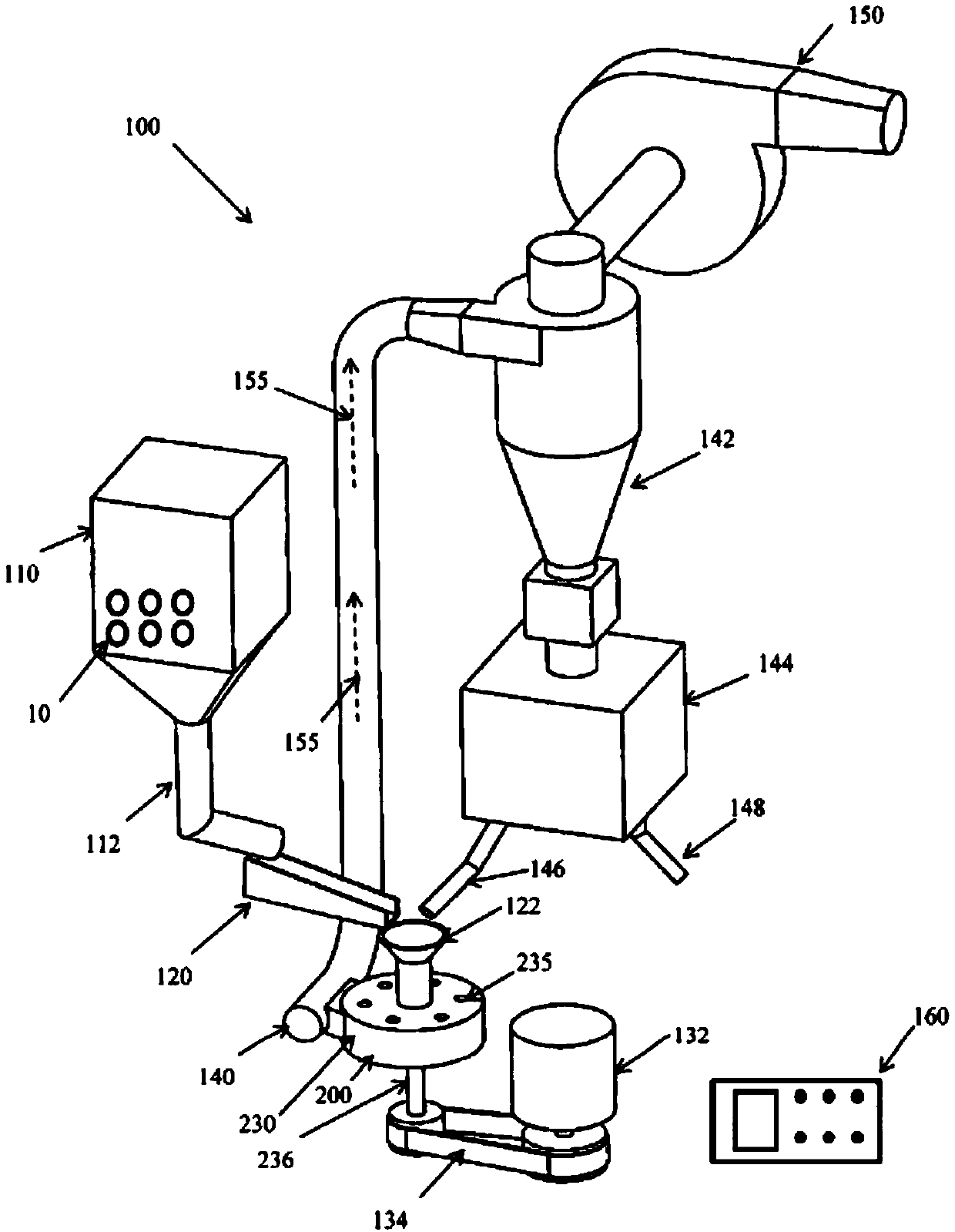

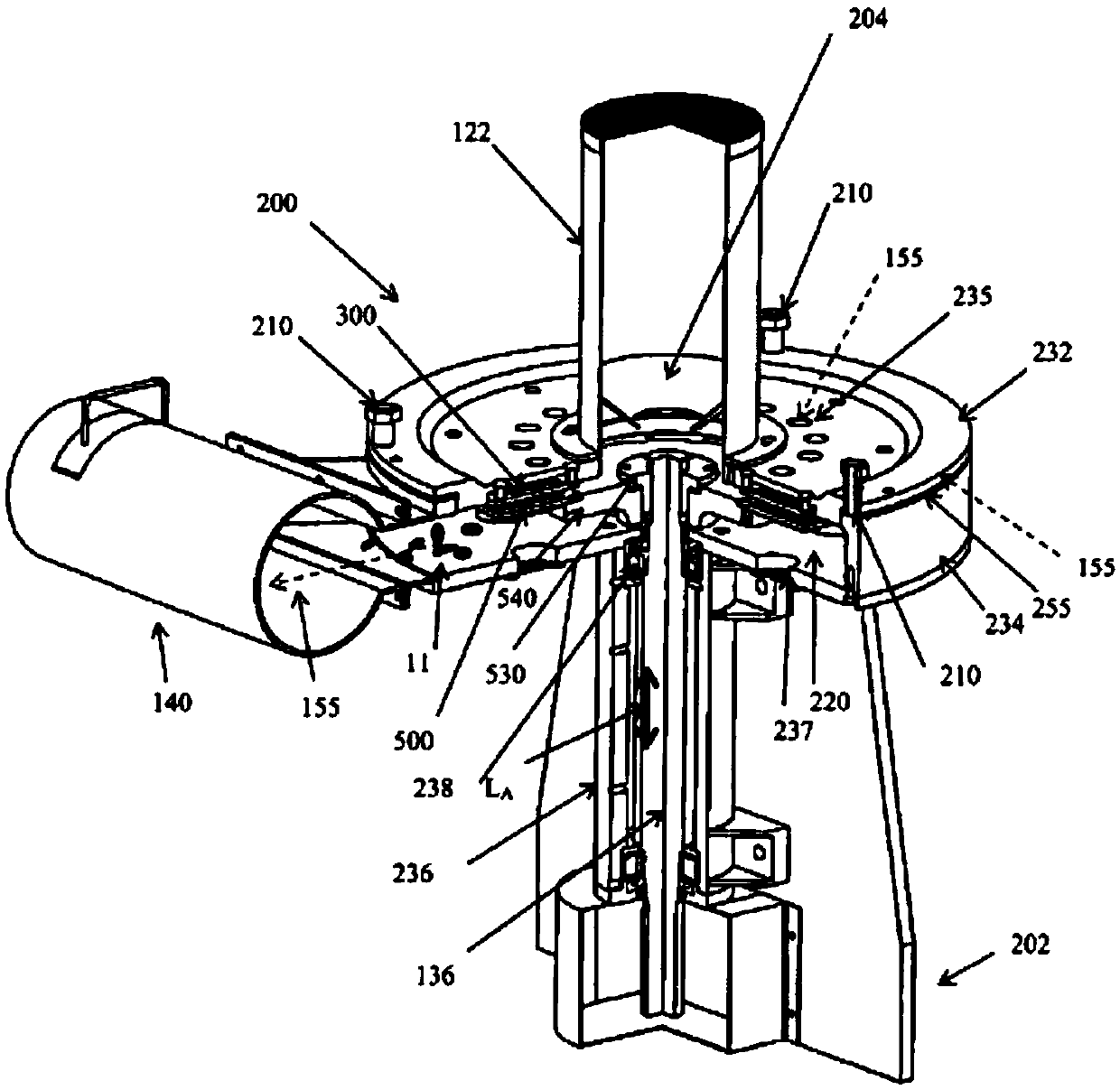

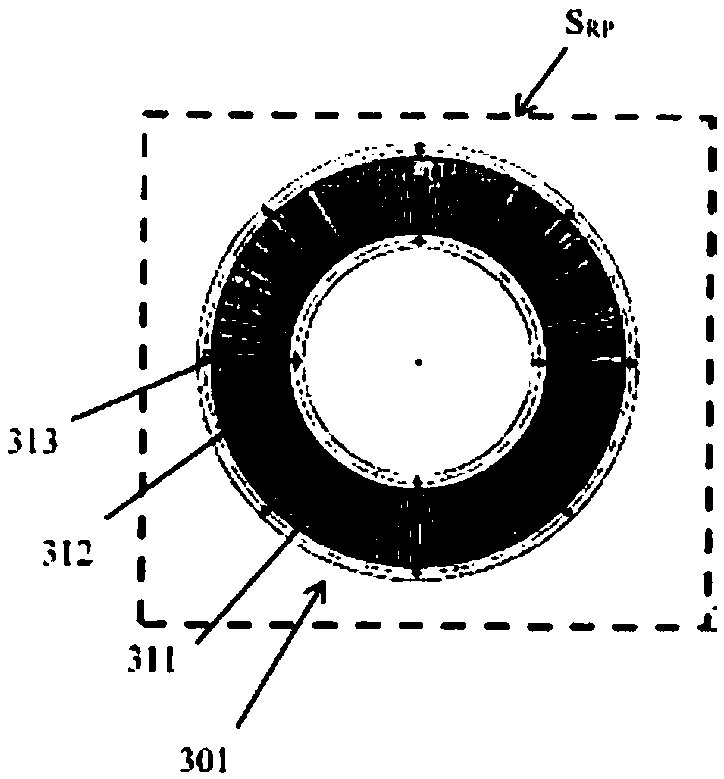

[0056] Such as figure 1 As shown, in one embodiment of the present invention, there is provided a shredder or system, generally indicated by the reference numeral 100 , for pulverizing an input material, generally indicated by the reference numeral 10 . The input material 10 is generally held in a hopper 110 having an input chute 112 leading to a tray 120 which allows the input material 10 to fall into the hopper 122 . The funnel 122 is connected to the mill assembly, generally indicated by reference numeral 200 . Milling assembly 200 comprises, accommodates fixed disc 300 and rotating disc 500 (in figure 1 Not shown in the mill shell 230 of).

[0057] Shredder 100 also includes motor 132 for rotating shaft 136 by means of belt 134 or any other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com