Adaptive Hermetic Sealing System for Flat Glass Panel Assemblies

An air-tight, flat element technology, applied in parallel glass structures, climate change adaptation, building components, etc., can solve the problems of wrinkling, leaking, and breaking of chaff, and achieve the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

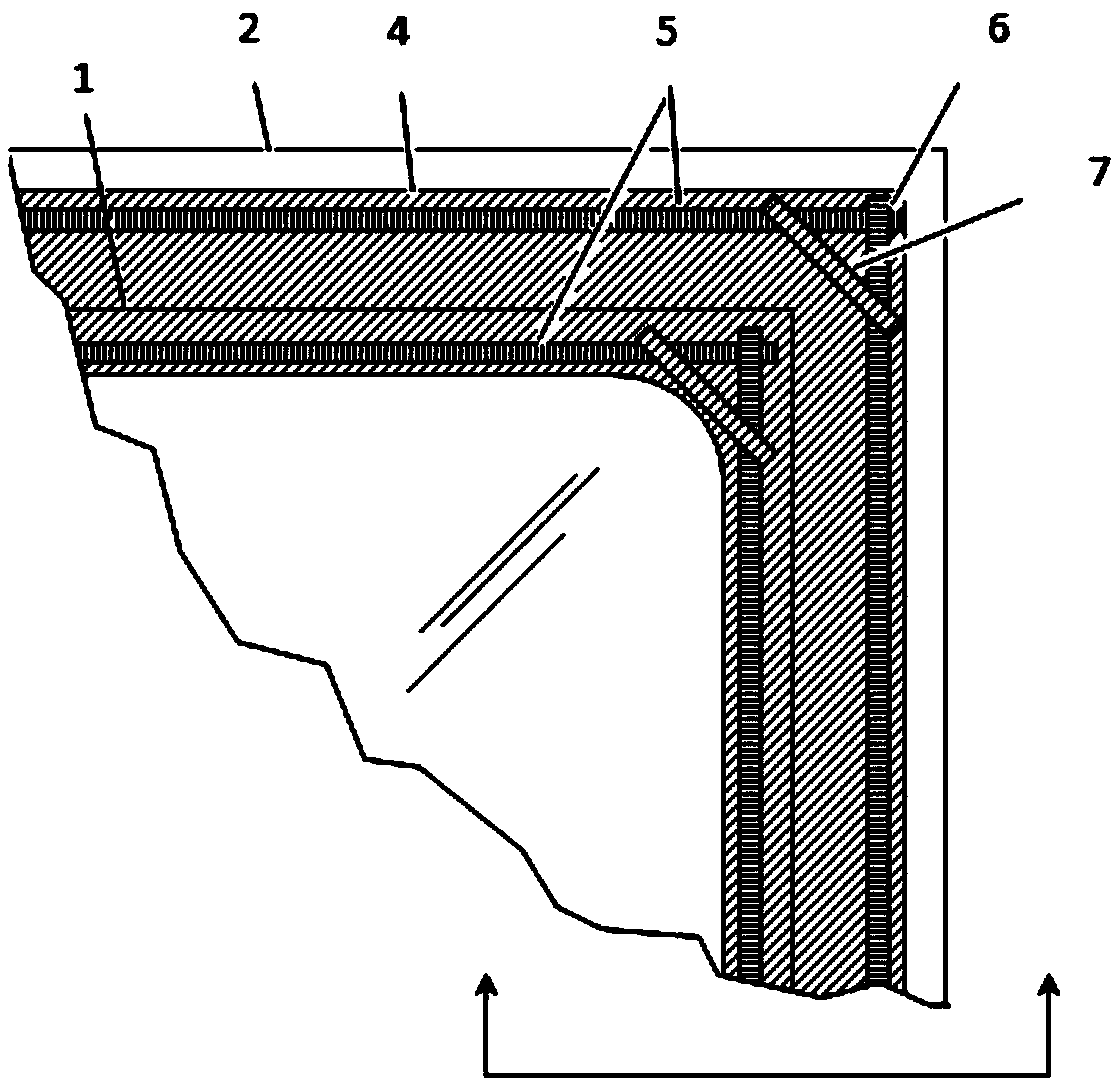

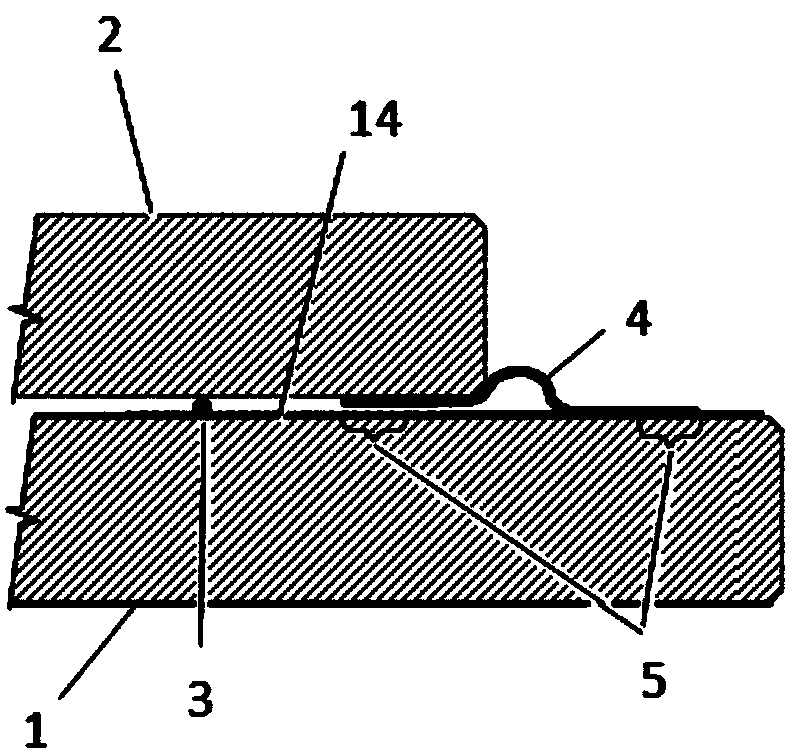

[0066] Example 1: Square pieces of aluminum window screen were cut 9 inches by 9 inches and mounted concentrically on clean, untempered 10 inches by 10 inches soda lime glass such that these square Almost have a common center. Two layers of 1100 series aluminum foil, a 2 mil layer and a 1 mil layer, were placed together so that they could be simultaneously cut into 12" x 12" squares.

[0067] The double foil assembly is mounted on top of the screen with a common center to create equal foil overhang at each pane edge. The annular area of the glazing that is only covered by the foil but not the screen can be used to provide a location for the weld line. This stacked assembly was mounted on the table top (used as an anvil) of a custom designed 100 watt ultrasonic seam welder.

[0068] A single continuous weld line is manufactured to weld the foil to the side glass surface adjacent the edge of the glazing, the weld line following a straight weld path except at the corners wher...

example 2

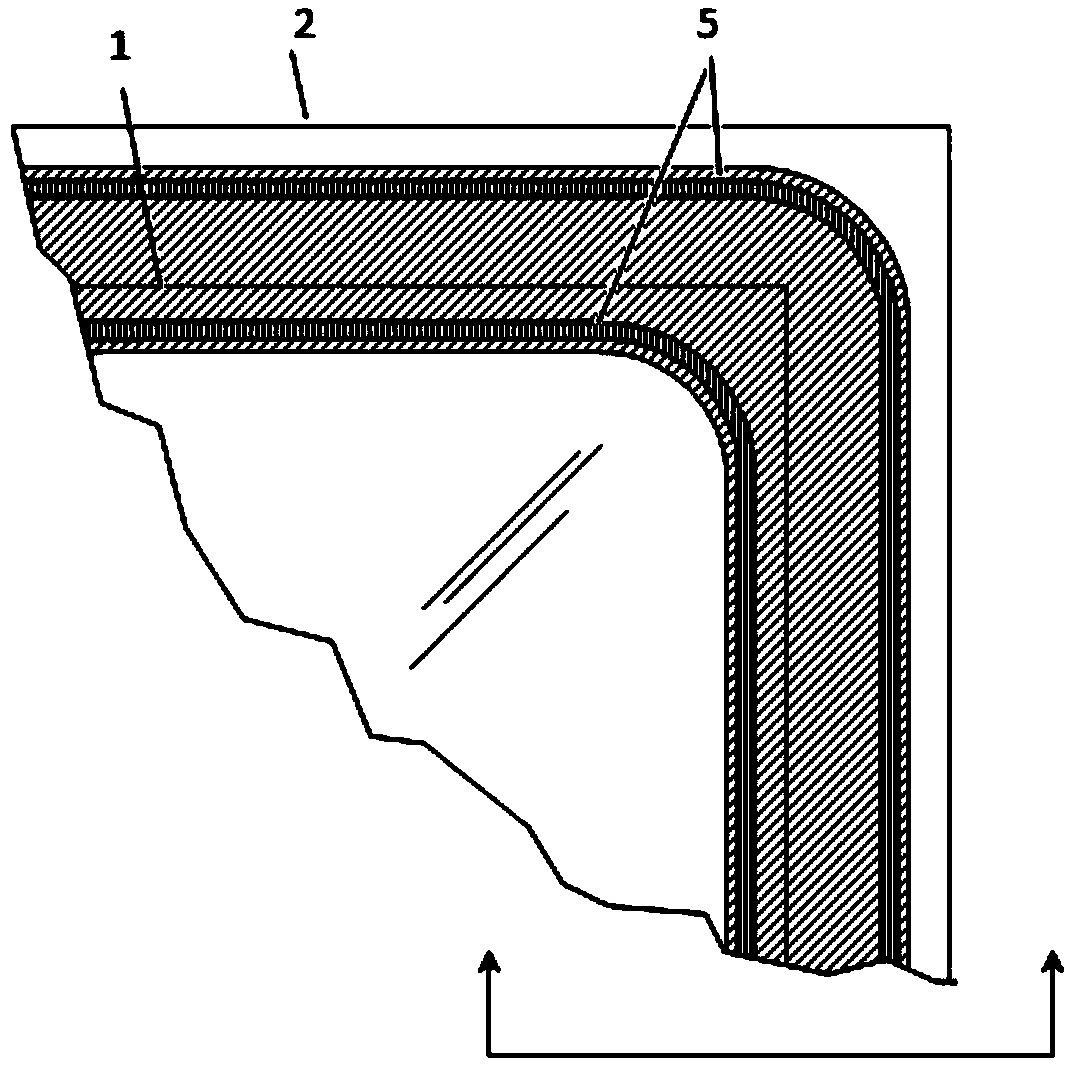

[0070] Example 2: From the test assembly produced in Example 1, the foil and screen were removed from the inside area of the closed circular weld, leaving only a continuous and jointless double layer of foil welded to the outside edge of the 10 inch square window pane strip. According to a co-pending patent application, a clean 12-inch by 12-inch soda-lime glazing with a low-E coating sputtered on one side is disposed on its coated surface about 125 microns thick and arranged in a 20 mm by 20 Several metal spacers in a grid pattern of millimeters. The 10 inch square glass and foil assembly is laid on top of the spacer of the 12 inch square windowpane with the foil sandwiched between the double panes so that the two panes have a common center, and Creates an equal amount of foil overhang on each pane edge. The annular area of this larger pane can be used to provide a location for the weld seam. The stacked assemblies were joined together using the equipment and technique...

example 3

[0073] Example 3: Reference Figure 13 , forming a highly airtight seal around a rectangular neutron detector airtight container of 1 m x 1 m x 1 cm. The airtight container is used to fill the argon and induction device. The airtight container comprises two parallel panes 1, 2, a seal and a glass edge spacer 41. An uncoated transparent soda-lime pane of 1 m x 1 m is used for pane 1, while an uncoated soda-lime pane of 0.975 m x 0.975 m is used. Coated transparent soda-lime glazing is used for window pane 2. Four glass edge spacers 41 (e.g., 0.965 meters long and having a 1 cm x 1 cm cross-section) are rigidly and hermetically bonded to the window pane 2 with solder glass 42, each spacer adjacent to one of the window panes 2. edge. Similarly, the corner joints between the four glass spacers 42 are filled with solder glass to form a highly hermetic seal when heated to 450°C.

[0074] After cooling, the excess solder glass weld path on the corner joints that protrudes intenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com