Cutting system, system for obtaining sample of plant material comprising the same, and method

A cutting system and cutting element technology are applied in the field of systems for obtaining plant material samples, and can solve problems such as inability to realize automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

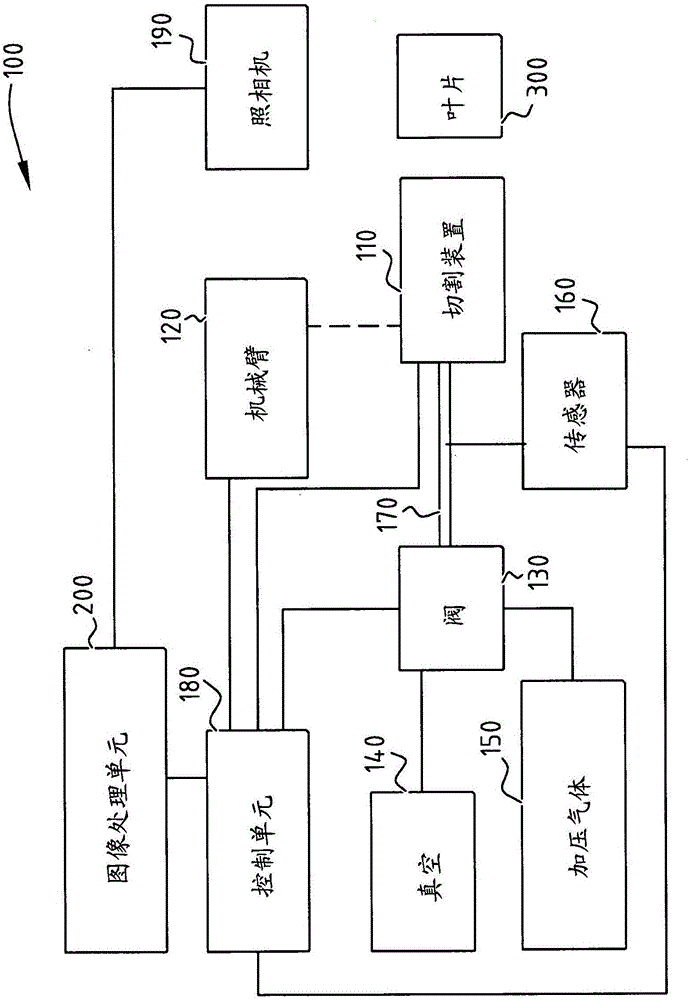

[0044] figure 1 A system 100 according to the invention is shown. The system includes a cutting device 110 . The system is connected to a robotic arm 120 on which the cutting device 110 is mounted. A vacuum source 140 and a pressurized gas source 150 are employed to obtain suction and thrust, respectively. A valve unit 130 is used to switch between the two sources. The sensor 160 is used to measure the pressure in the conduit 170 between the cutting device 110 and the valve unit 130 .

[0045] The system 100 also includes a control unit 180 to control the operation of the robot arm 120 , control the switching operation of the valve unit 130 , and control the driving unit of the cutting device 110 .

[0046] In addition, the system 100 includes one or more optical cameras 190 , and the image output from the optical cameras 190 is processed by the image processing unit 200 . The image output from the image processing unit 200 is output to the control unit 180 .

[0047] Ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com