Gate driver controlling a collector to emitter voltage variation of an electronic switch and circuits including the gate driver

A gate driver, power electronic switch technology, applied in electronic switches, circuits, regulating electrical variables, etc., can solve the problems of reducing the performance of the commutation unit, long current switching time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

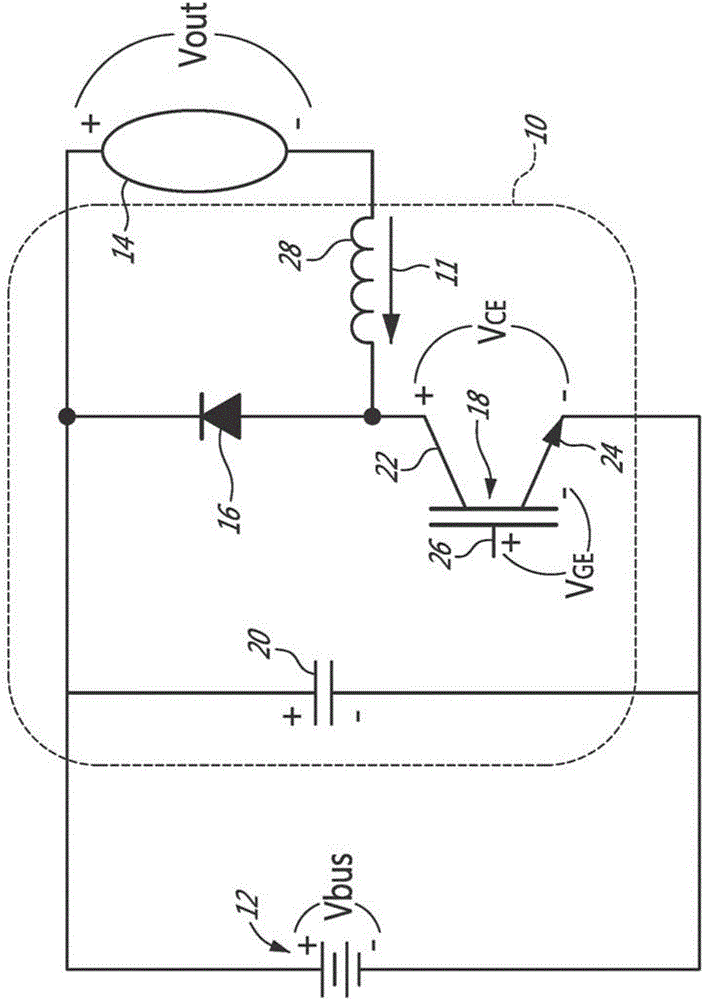

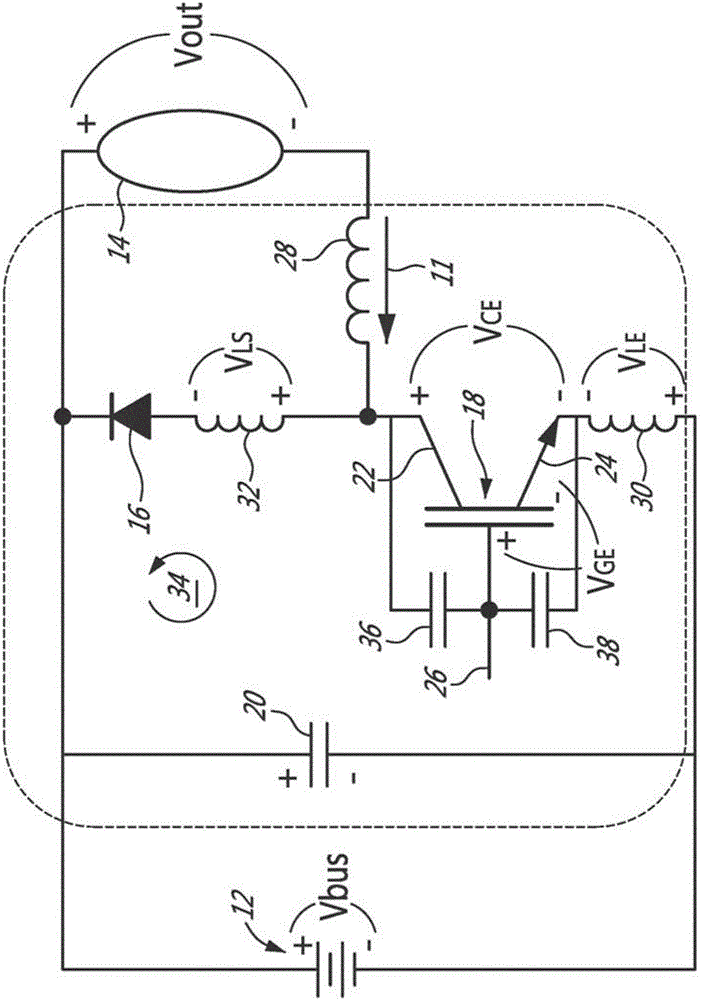

[0044] Aspects of the present disclosure generally address one or more of the problem of overvoltage in the commutation unit when turned off and the problem of excessive recovery current in the commutation unit when it is turned on. In general, it is desirable to reduce the risk of failure of power electronic switches when overvoltage and excessive recovery current are under control. This can be achieved at least in part by keeping the power electronic switches close to their linear region during the commutation process.

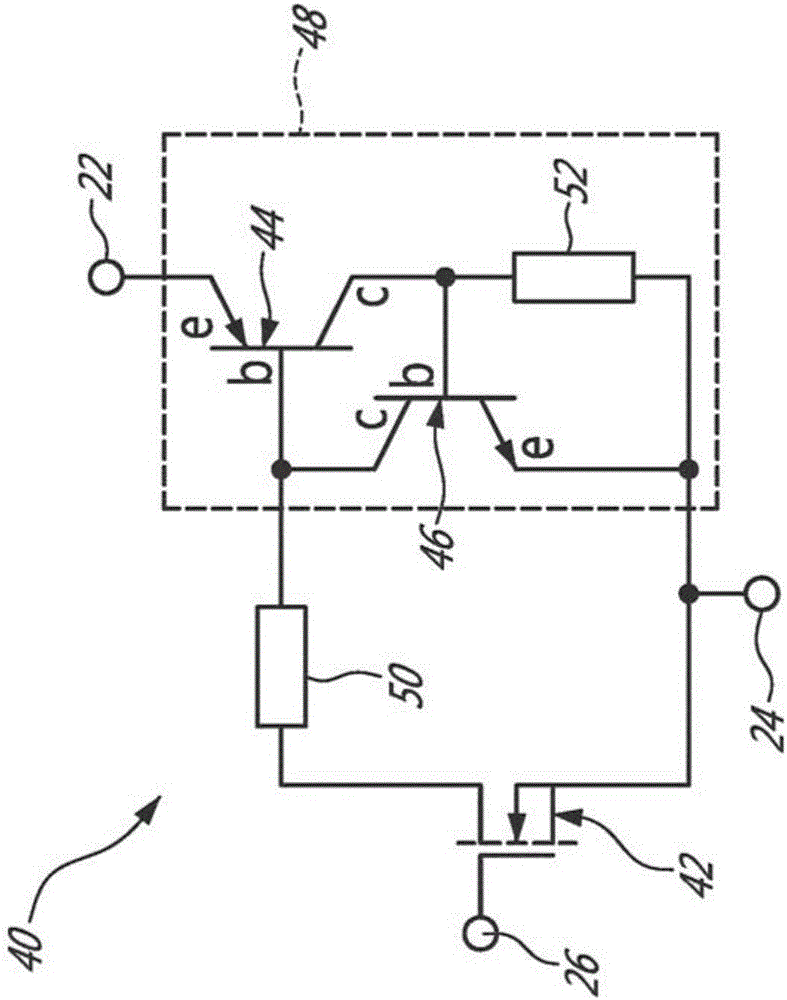

[0045] In one aspect, the present disclosure introduces a gate driver for driving a commutation unit including power electronic switches. A power electronic switch has a collector, a gate and an emitter. The insulation between the collector and the gate forms a parasitic capacitance. The gate driver is configured as a pair of current sources connected to the gate of the power electronic switch, the current sources respectively providing a turn-on current a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com