Novel modular plate-type plasma ozone generator

An ozone generator and modular technology, applied in the field of ion ozone generators, can solve the problems of many joints, difficult maintenance, large deformation, etc., and achieve the effects of large plasma volume, large ozone production, and small concentration attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

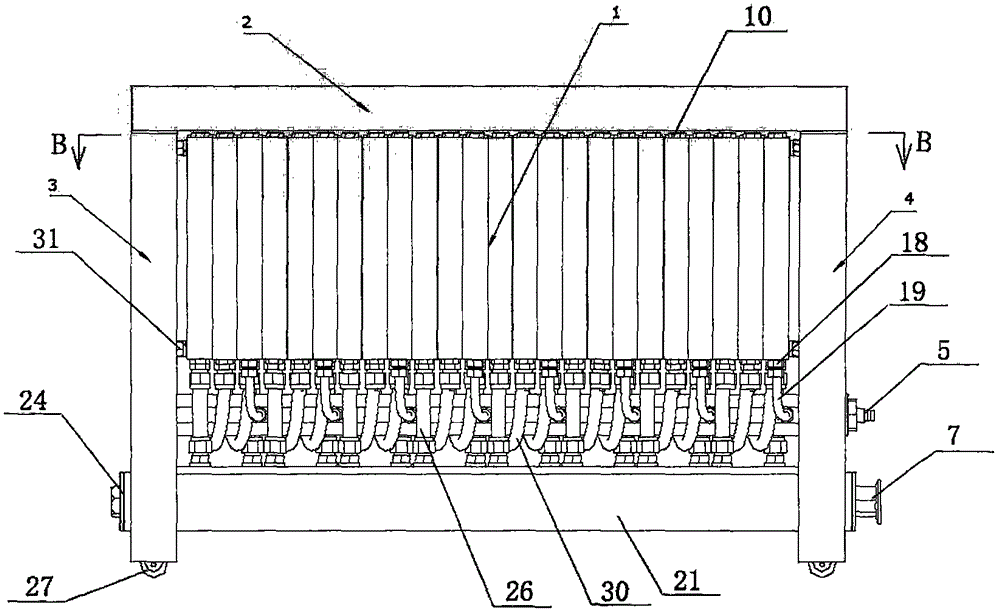

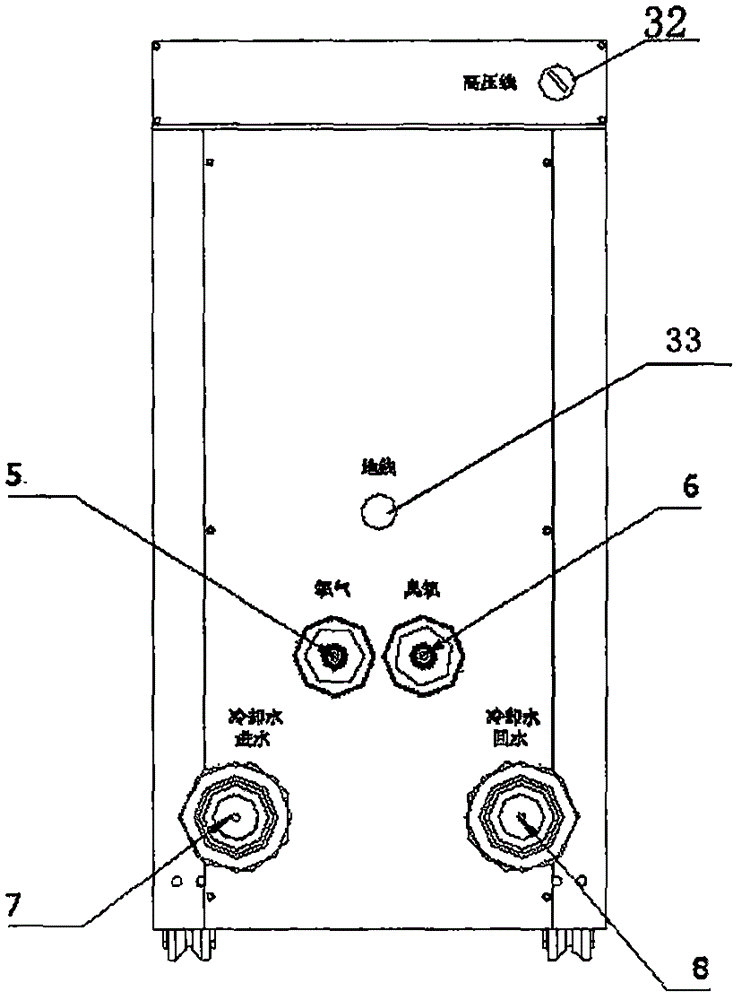

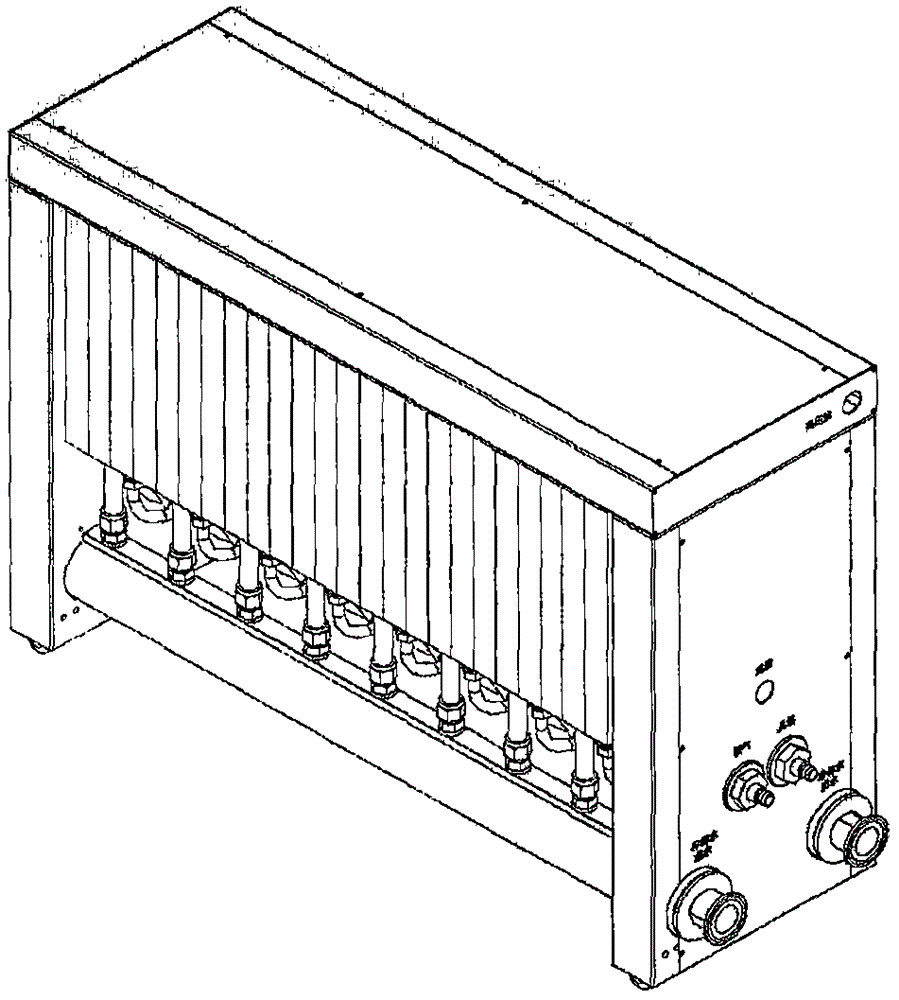

[0018] A new type of modular plate plasma ozone generator, such as Figure 1-Figure 3 It consists of 1: 24 sets of discharge discharge unit assembly, 2: high voltage electrode row assembly, 3) generator front support assembly, 4) generator rear support assembly, 5) oxygen pipeline assembly, 6) ozone pipeline assembly , 7 cooling water inlet pipeline assembly, 8 cooling water return pipeline assembly and other components. The assembly sequence is to first install the 24 sets of discharge unit assemblies. During the assembly process, it must be completed by hydraulic special tooling, and then the generator front support assembly and generator rear support assembly are installed together with the 24 sets of discharge unit assemblies. Fasten it, and then install the oxygen pipeline assembly and ozone pipeline assembly to figure 1 position shown; then install the cooling water inlet pipe assembly and the cooling water return pipe assembly to the figure 1 Position shown; finally f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com