Clean poly-film drilling fluid used for coal bed methane and preparation method thereof

A technology of drilling fluid and coalbed methane, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as pollution, gel-breaking coal seam, coal seam collapse and block, etc., to achieve fast gel-breaking, excellent performance, and small damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Measure 360mL of clear water and place it in the slurry cup of the mixer, adjust the stirring speed of the mixer to 73r / min, and add 20g of film-forming agent, 8g of film-fixing agent, 8g of degradable film-strengthening agent, 8g of degradable Emulsion fluid loss reducer, stir for 10 minutes;

[0023] 2) Under the condition of a stirring speed of 73r / min, add 4g of coal seam cleaner with a shear pump and stir for 30min;

[0024] 3) Under the condition of a stirring speed of 73r / min, add 40g of inert inorganic salt with a shear pump, and stir for 1 hour to obtain the poly-film drilling fluid for cleaning coalbed methane according to the present invention.

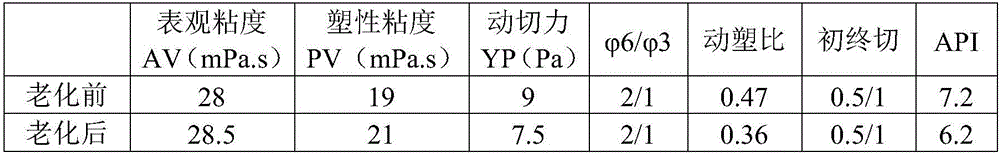

[0025] The rheological parameters of the polymembrane drilling fluids used for coalbed methane cleaning prepared according to the above method after aging at room temperature and high temperature are respectively measured below.

[0026] High temperature aging method: Put the drilling fluid prepared by the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com