Water-diluent phenolic resin adhesive and preparation method thereof

A technology of phenolic resin and adhesive, which is applied in the direction of aldehyde/ketone condensation polymer adhesive, adhesive type, polymer adhesive additive, etc., which can solve the problem of over-curing or under-curing of phenolic resin and the difficulty of phenolic resin Evenly mixed, poor solubility of phenolic resin, etc., to achieve excellent performance, unique rheological properties, and solve the effect of glue sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

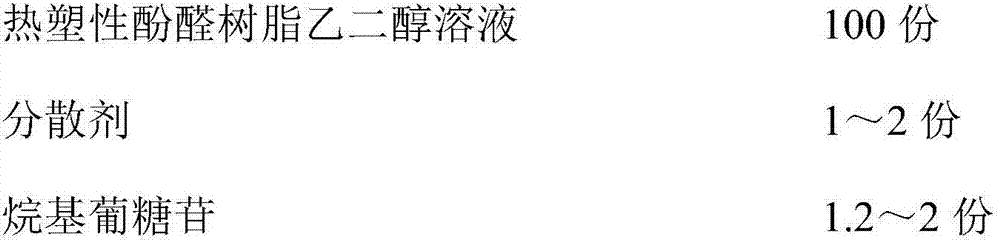

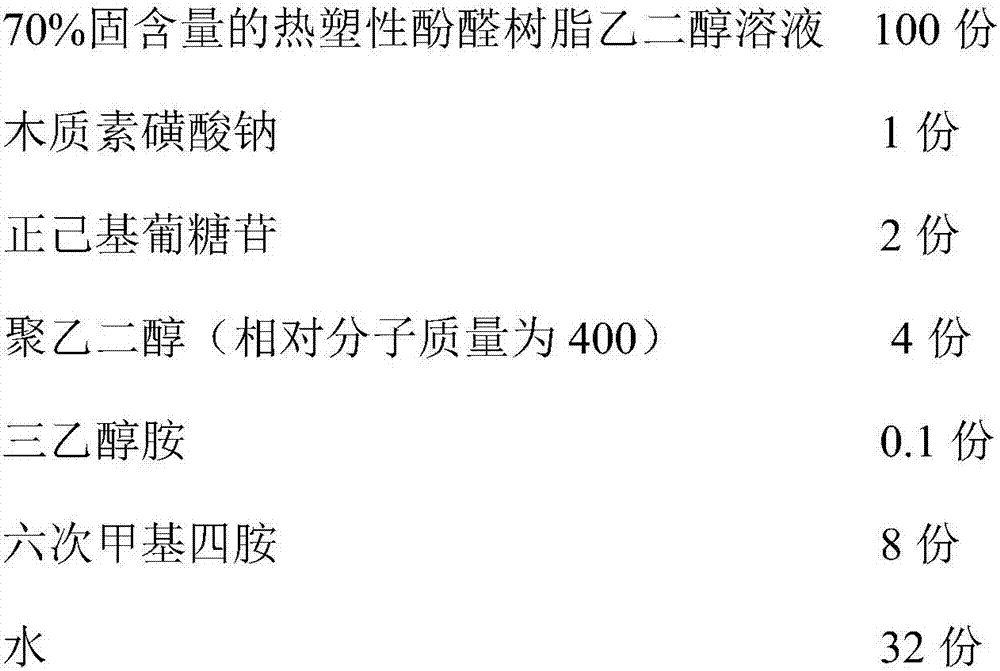

[0020] The parts by weight ratio of each component in the water-diluted phenolic resin binder is as follows:

[0021]

[0022] Follow the steps below to prepare a water-reducible phenolic resin adhesive:

[0023] (1) Weigh sodium lignosulfonate, n-hexyl glucoside, polyethylene glycol, triethanolamine, hexamethylenetetramine and water in sequence according to the formula requirements, stir to dissolve, and mix evenly to obtain a water phase mixture material.

[0024] (2) Add the water phase mixture material prepared by step (1) into the thermoplastic phenolic resin ethylene glycol solution with 70% solid content required by the formula metering, stir while adding, and get water-diluted phenolic resin after mixing evenly Resin binder.

Embodiment 2

[0026] The parts by weight ratio of each component in the water-diluted phenolic resin binder is as follows:

[0027]

[0028] Follow the steps below to prepare a water-reducible phenolic resin adhesive:

[0029] (1) Weigh sodium lignosulfonate, isooctyl glucoside, polyethylene glycol, hexamethylenetetramine and water sequentially according to the formula requirements, stir to dissolve and mix evenly to prepare a water phase mixture material.

[0030] (2) Add the water phase mixture material prepared by step (1) into the thermoplastic phenolic resin ethylene glycol solution with 70% solid content required by the formula metering, stir while adding, and get water-diluted phenolic resin after mixing evenly Resin binder.

Embodiment 3

[0032] The parts by weight ratio of each component in the water-diluted phenolic resin binder is as follows:

[0033]

[0034]

[0035] Follow the steps below to prepare a water-reducible phenolic resin adhesive:

[0036] (1) Weigh calcium lignosulfonate, isooctyl glucoside, polyethylene glycol, hexamethylenetetramine and water sequentially according to the formula requirements, stir to dissolve and mix evenly to obtain a water phase mixture material.

[0037] (2) Add the water phase mixture material prepared by step (1) into the thermoplastic phenolic resin ethylene glycol solution with 70% solid content required by the formula metering, stir while adding, and get water-diluted phenolic resin after mixing evenly Resin binder.

[0038] Two, the preparation of organic solvent type phenolic resin binder reference sample (comparative example)

[0039] The parts by weight ratio of each component in the organic solvent type phenolic resin binder is as follows:

[0040] 70%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com