Non-settling glycol based magnetorheological fluids

一种磁流变流体、二醇的技术,应用在磁性物体、磁性液体、磁性材料等方向,能够解决泡沫等问题,达到低起泡性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

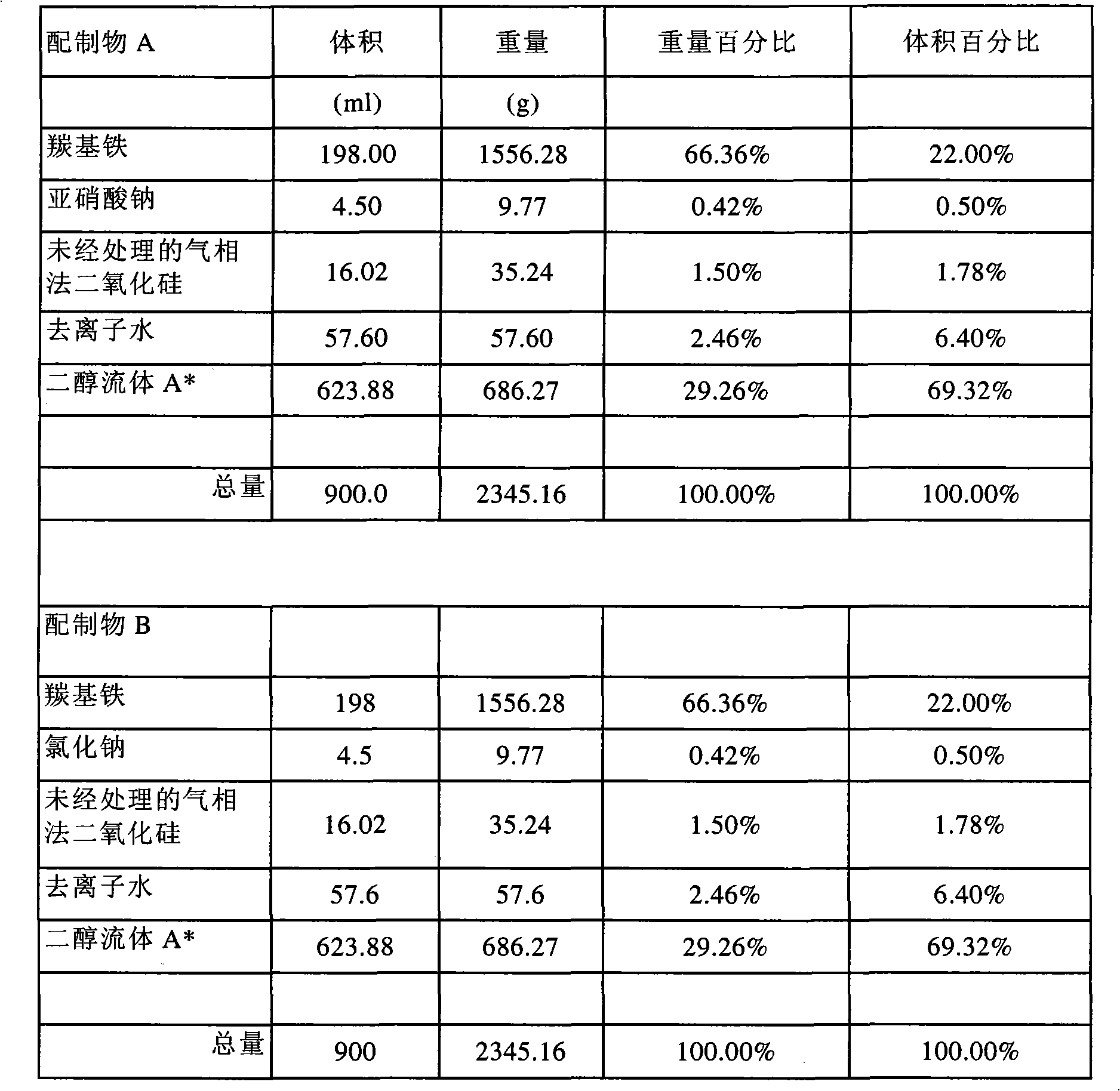

Embodiment 1

[0047]

[0048] *Glycol Fluid A comprises a glycol mixture formed from ethylene glycol to propylene glycol in a 70 / 30 ratio with an alkyl alkanolamine additive.

[0049] The formulations described in Examples 1 and 2 yielded fluids that did not develop a clear layer after standing overnight without stirring, but had a thick yogurt-like consistency.

[0050] The fluid flows easily after shaking by hand briefly, and continues to flow easily for at least 10 minutes after agitation.

Embodiment 2

[0052] Table 1: Effect of different types of thickeners

[0053]

Preparation

thickener

specific surface area

(m 2 / g)

24 hours

1

200

0

[0054]

Preparation

thickener

specific surface area

(m 2 / g)

24 hours

2

150

0

3

380

4

4

n / a

14

5

Treated Fumed Silica

225

7

6

Treated Fumed Silica

125

24

7

Treated Fumed Silica

100

3

[0055] All formulations described above were prepared with 66% by weight iron carbonyl, 2.45% by weight water, 1.5% by weight thickener and 0.83% by weight sodium chloride as ionic thixotropic additive. The settling properties of the above formulations were checked by allowing them to stand undisturbed for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com