Nickel-metal hydride battery positive electrode slurry, nickel-metal hydride battery positive electrode plate and nickel-metal hydride battery

A technology for nickel-hydrogen battery and positive electrode slurry, which is applied in the field of nickel-hydrogen battery positive electrode sheet and nickel-hydrogen battery and nickel-hydrogen battery positive electrode slurry, can solve the problems of increasing electrode impedance, shortening battery cycle life, and easy sedimentation of the slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

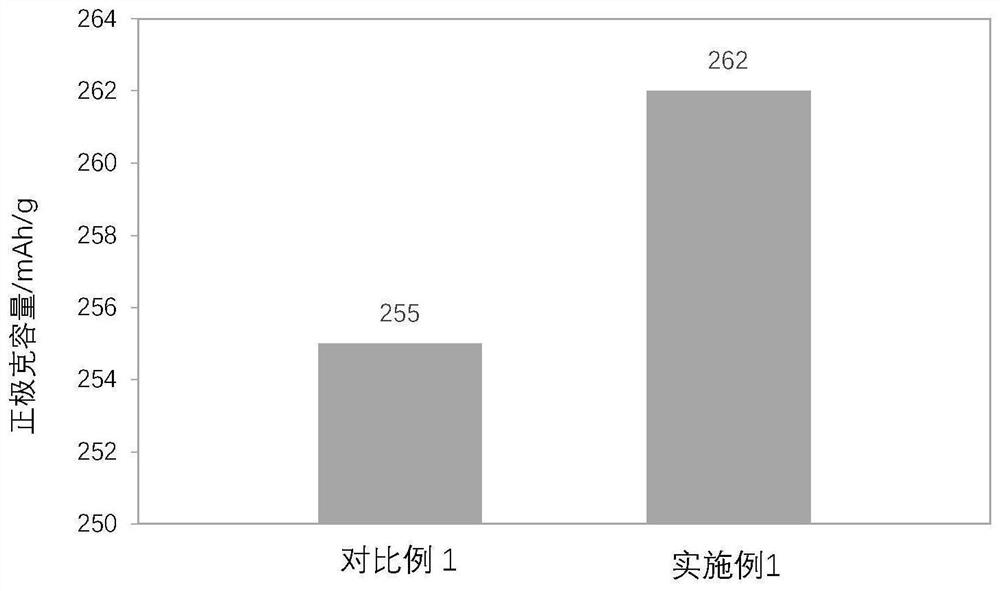

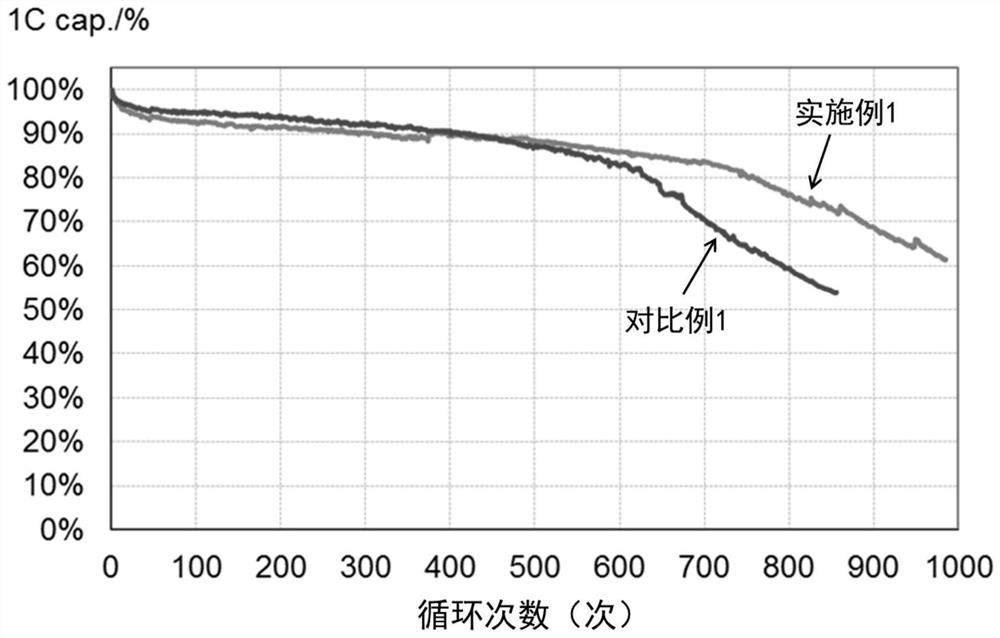

Embodiment 1

[0030] This embodiment provides a nickel-hydrogen battery cathode slurry, a nickel-hydrogen battery cathode sheet, and a nickel-hydrogen battery.

[0031] The positive electrode slurry for the nickel-hydrogen battery includes 100 parts by mass of nickel hydroxide (positive electrode active material), 2 parts by mass of yttrium oxide (additive), 1 part by mass of super P conductive carbon black (conductive agent), 0.03 parts by mass of fixed You gum, 0.04 parts by mass of carboxymethyl cellulose, and 0.5 parts by mass of polytetrafluoroethylene emulsion (PTFE solid content 60 wt%).

[0032] The nickel-hydrogen battery cathode sheet is prepared by coating the above-mentioned nickel-hydrogen battery cathode slurry on a foamed nickel current collector.

[0033] The nickel-hydrogen battery comprises a nickel-hydrogen battery negative electrode sheet, a polypropylene diaphragm, an electrolyte and the above-mentioned nickel-hydrogen battery positive electrode sheet.

[0034] The pre...

Embodiment 2

[0052] This embodiment provides a positive electrode slurry for a nickel-metal hydride battery. The difference from Embodiment 1 lies in that the content of Diutan gum is 0.04 parts by mass, and the content of carboxymethyl cellulose is 0.1 parts by mass. The positive electrode slurry of the nickel-hydrogen battery has good positive electrode active material utilization rate and battery cycle life of the battery.

Embodiment 3

[0054] This embodiment provides a positive electrode slurry for a nickel-metal hydride battery. The difference from Embodiment 1 is that the content of Diutan gum is 0.01 parts by mass, and the content of carboxymethyl cellulose is 0.092 parts by mass. The positive electrode slurry of the nickel-hydrogen battery has good positive electrode active material utilization rate and battery cycle life of the battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com