Marinated egg product capable of improving unfreezing layering phenomenon after quick freezing and preparation method of marinated egg product

A technology for marinated eggs and products, which is applied in the field of marinated egg products and marinated egg products that improve the phenomenon of thawing and layering after quick-freezing, and can solve the problems affecting the effect of sensory evaluation, the change of marinated flavor, and the dehydration of egg whites, etc., and achieve good results. Non-specific protective effect, increase viscosity, increase the effect of health care performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

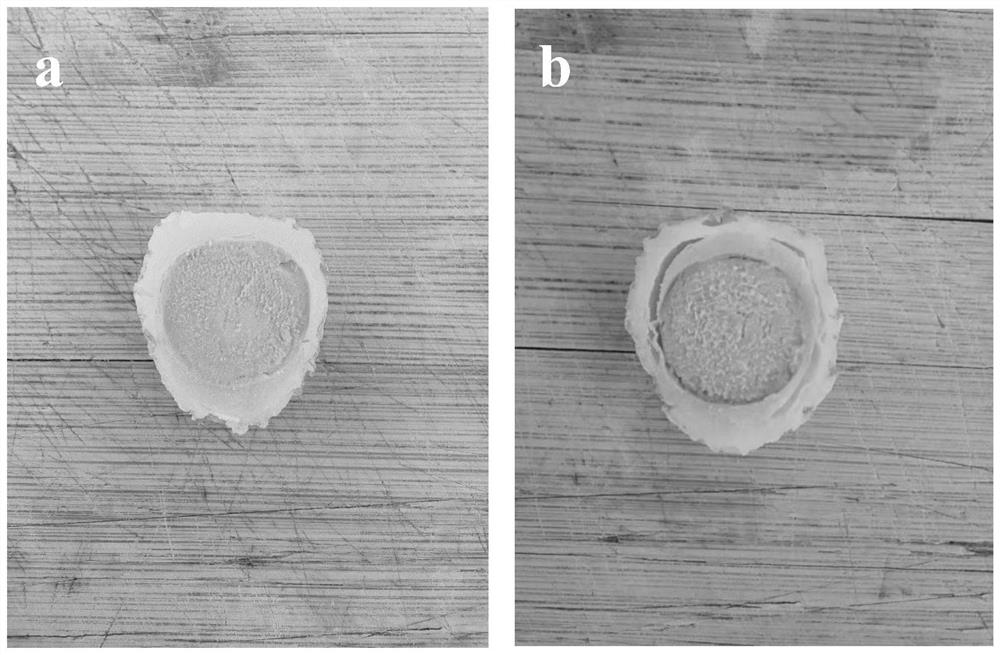

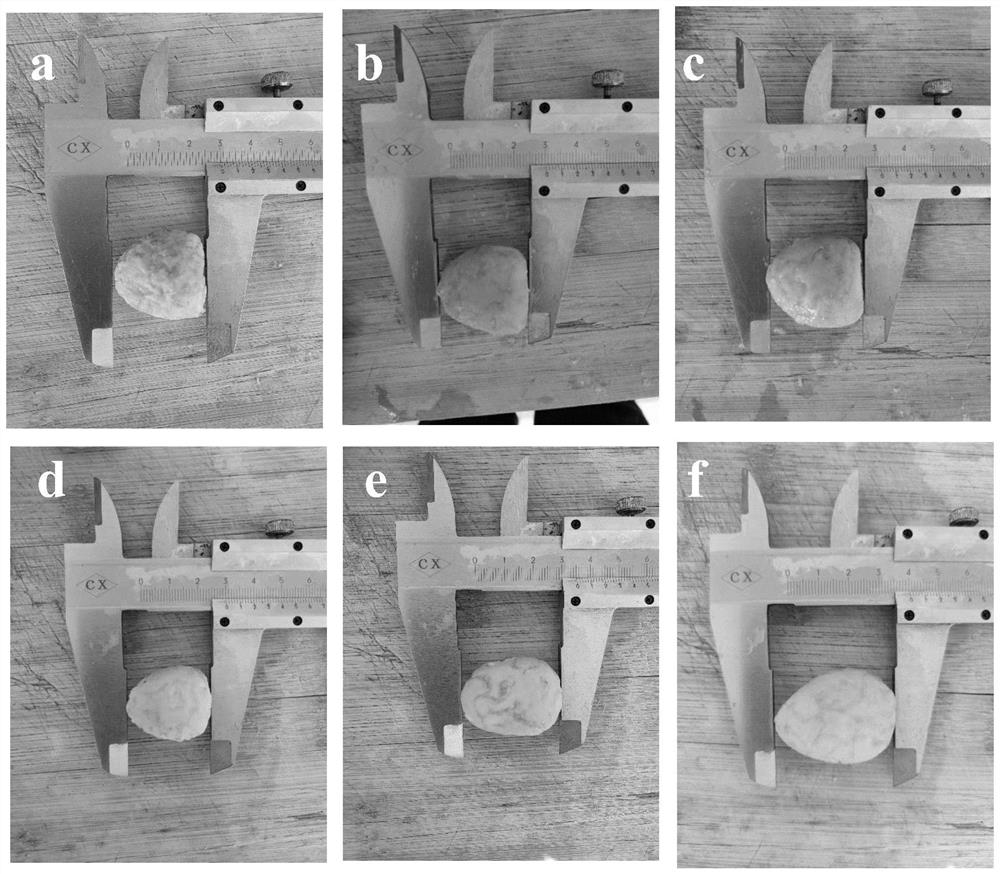

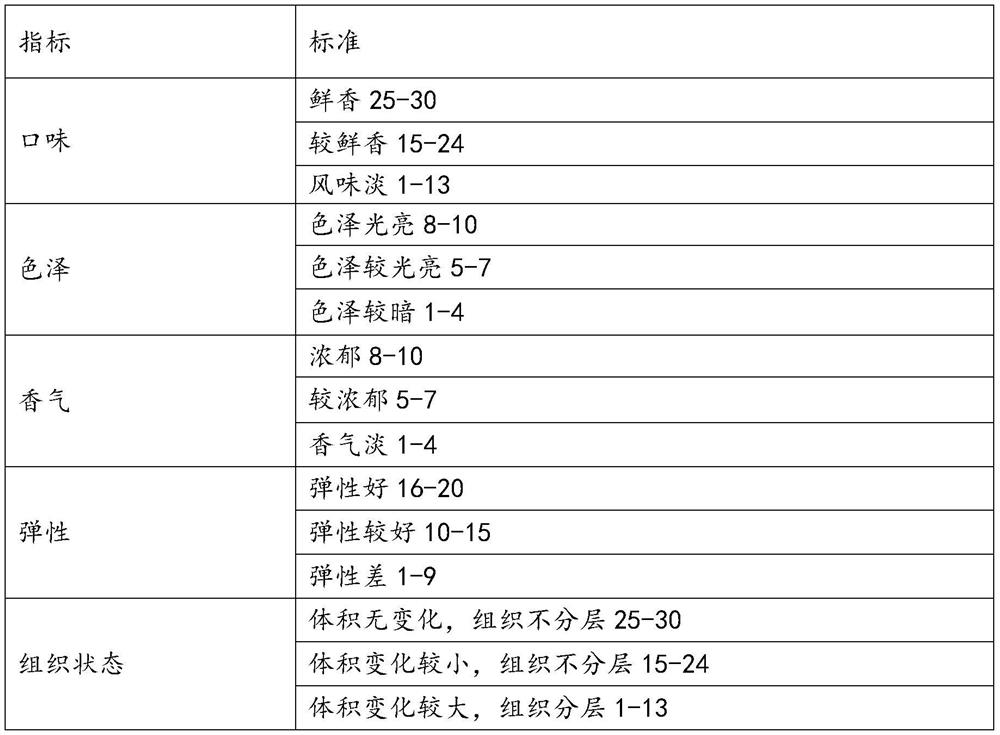

[0039] A marinated egg product that improves the thawing stratification phenomenon after quick-freezing and a preparation method thereof:

[0040] The marinade composition formula: 0.1 parts of xanthan gum, 1.2 parts of trehalose, 1.6 parts of table salt, 1.2 parts of white sugar, 1.8 parts of spices and 110 parts of water.

[0041] Preparation:

[0042] (1) Pretreatment of eggs: select fresh quail eggs that are clean and free of impurities on the surface, wash them and boil them in water at 97°C for 20 minutes, then take them out and place them in cold water at 4°C immediately to remove the shells;

[0043] (2) Stewing: Weigh the composition, mix the pretreated eggs and the composition at a mass ratio of 1:1.5, and cook for 80 minutes at a temperature of 98°C.

[0044] (3) Soaking in cold storage: after marinating, take out the egg product immersed in the marinade composition, and refrigerate for 12 hours at 4°C;

[0045] (4) Quick-freezing: After refrigerating and soaking ...

Embodiment 2

[0047] A marinated egg product that improves the thawing stratification phenomenon after quick-freezing and a preparation method thereof:

[0048] The marinade composition formula: 0.1 parts of xanthan gum, 1.2 parts of trehalose, 1.6 parts of table salt, 1.2 parts of white sugar, 1.8 parts of spices and 110 parts of water.

[0049] Preparation:

[0050] (1) Pretreatment of eggs: select fresh quail eggs that are clean and free of impurities on the surface, wash them, put them in water at 97°C and cook for 20 minutes, then take them out and put them in cold water at 4°C immediately to remove the eggshells;

[0051] (2) Put the eggs that have been treated with cold water and shelled in an oil pan, and fry them at an oil temperature of 160-180°C until the surface of the eggs takes on the shape of tiger skin.

[0052] (3) Stewing: weigh the composition, mix the pretreated eggs and the composition at a mass ratio of 1:1.5, and cook at 98°C for 80 minutes.

[0053] (4) Soaking in ...

Embodiment 3

[0056] A marinated egg product that improves the thawing stratification phenomenon after quick-freezing and a preparation method thereof:

[0057] The marinade composition formula: 0.5 parts of xanthan gum, 1.5 parts of trehalose, 1.6 parts of table salt, 1.5 parts of white sugar, 4 parts of spices and 115 parts of water.

[0058] Preparation:

[0059] (1) Pretreatment of eggs: select fresh quail eggs that are clean and free of impurities on the surface, wash them and boil them in water at 97°C for 20 minutes, then take them out and place them in cold water at 2°C immediately to remove the eggshells;

[0060] (2) Stewing: Weigh the composition, mix the pretreated eggs and the composition at a mass ratio of 1:1, and cook at 98°C for 90 minutes.

[0061] (3) Soaking in cold storage: after marinating, take out the egg product immersed in the marinade composition, and refrigerate for 12 hours at 4°C;

[0062] (4) Quick-freezing: After refrigerating and soaking the marinated eggs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com