Diesel engine aftertreatment anti-crystallization heating mixing device

A technology of heating, mixing and post-treatment, which is applied to the electric control of exhaust treatment devices, exhaust devices, exhaust treatment, etc. It can solve the problems of reducing conversion efficiency and affecting catalytic reactions, so as to improve uniformity and promote urea heating. The effect of decomposing hydrolysis and improving the catalytic conversion efficiency of NOX

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

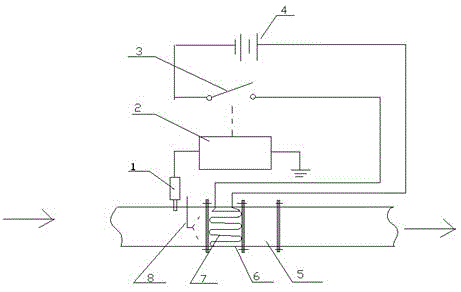

[0008] The present invention will be further described in detail according to accompanying drawing 1 below.

[0009] As shown in Figure 1, a diesel engine post-treatment heating and mixing device includes a temperature sensor 1, a relay 2, a power supply 4, a resistance wire 7, a switch 3, a resistance heating cylinder 6, a mixer 5 and a urea injection nozzle 8, and a resistance wire 7 Fixedly installed on the inner wall circumference of the resistance heating cylinder 6, the temperature sensor 1 is connected to the relay 2, the switch 3, the power supply 4, the resistance wire 7 and the relay 2 are connected in series, the resistance heating cylinder 6 is connected to the mixer 5 and located at the urea injection nozzle 8 within the spray area. Among them, when the switch 3 is closed, the temperature sensor 1, the relay 2, the power supply 4, and the resistance wire 7 form a closed circuit. When the exhaust gas temperature is higher than the set low temperature, the relay 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com