Steel wire-lined hollow high-voltage bare conductor

A steel wire, hollow technology, applied in the direction of power cables, electrical components, single-pipe conductors, etc., can solve problems such as limited capacity and poor ice melting effect, and achieve the effect of enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

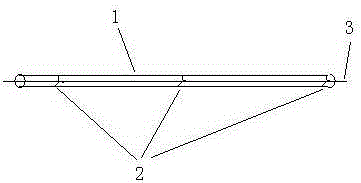

[0017] exist figure 1 In the first embodiment shown, the hollow aluminum tubular high-voltage wire (1) has an outer diameter of 30 mm and a tube wall thickness of 1 mm. The outer surface of the metal tube is exposed without covering any material.

[0018] In the tubular wire, a three-claw bracket made of plastic is arranged every 300mm, so that the steel wire at its center keeps a distance from the metal tube wall of good conductor without contact, and the center opening of all three-claw brackets (2) is 4mm The inner liner steel wire (3) with a diameter of 3 mm passes through the center through hole of the three-claw bracket made of plastic, and all the three-claw brackets made of plastic are evenly distributed.

[0019] In Embodiment 2, the hollow copper tubular high-voltage wire (1) has an outer diameter of 40 mm and a tube wall thickness of 0.5 mm. The outer surface of the metal tube is exposed without covering any material.

[0020] In the same high-voltage transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com