Method of sterilizing or inactivating heat-resistant spore-forming bacteria

A treatment method and heat-resistant technology, applied in heating, heating preservation of seeds, heating preservation of meat/fish, etc., can solve the problems of inability to obtain sufficient sterilization effect and difficulty in practical application, and achieve simple equipment, low income, and low price low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] Specific embodiments of the present invention will be described based on the drawings.

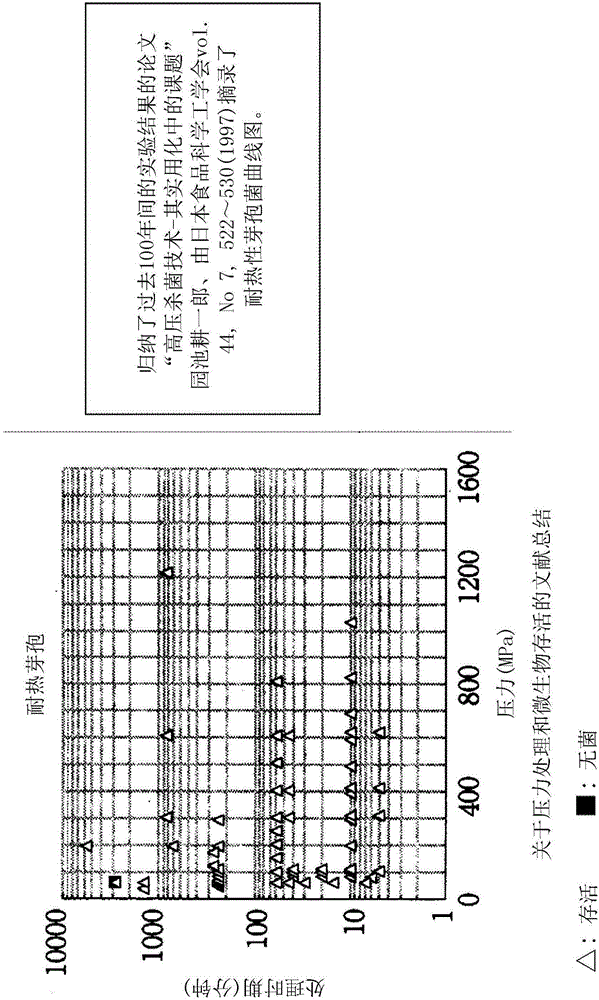

[0075] figure 1As mentioned above, a part of the paper published by Koichiro Sonoike on the bactericidal effect of high-pressure treatment on heat-resistant spores in the past 100 years is shown. The result that high pressure cannot be sterilized.

[0076] Regarding the sterilization of microorganisms by high-pressure treatment, the effects differ greatly between non-thermostable bacteria and thermostable bacteria.

[0077] That is, for non-heat-resistant bacteria, the effect of high-pressure treatment is remarkable, and it was also confirmed that heating during pressurization is more effective.

[0078] Thus, for example, in the case of most vegetative cells, Gram-negative bacteria, molds / yeasts, killed bacterial species are more observed.

[0079] However, as described above, heat-resistant spores have been shown to be difficult to sterilize at a pressure of 400 MPa or more, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com