Corn glutinous rice cake and preparation method thereof

A production method and technology of corn, which is applied in the field of Ciba food, can solve the problems of single material, low energy, shelf life of changing taste, etc., and achieve the effect of delicate and shiny appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

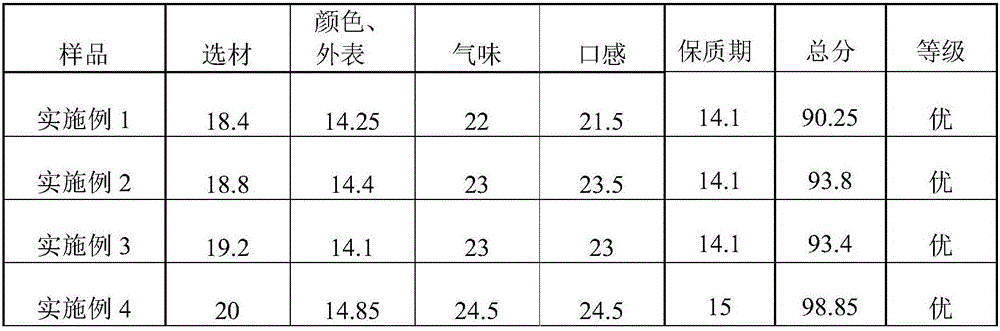

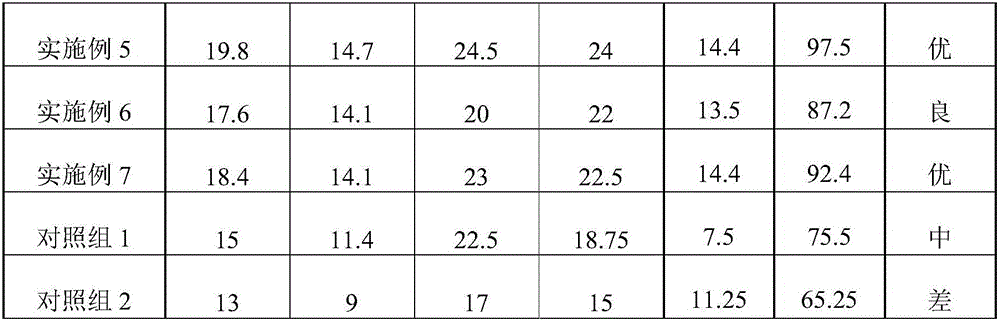

Examples

Embodiment 1

[0057] (1) Take the freshly picked common corn at the stage of milk maturity, peel off, remove the beard and impurities, then clean it, and perform manual threshing.

[0058] (2) Use a pulverizer to pulverize the detached corn kernels into paste particles.

[0059] (3) Put the pulverized pasty particles into egg tart molds and steam them in a steamer. The steaming temperature is 90°C and the steaming time is 6 minutes.

[0060] (4) The steamed corn glutinous rice cake is placed in the packaging bag and vacuumized and sealed. In the vacuum pumping process, the pumping rate of the vacuum pump is 50m / h, and the pumping time is 16s.

[0061] (5) Put the packaged corn glutinous rice cake into an autoclave, wherein the pressure of the sterilization process is set to 1.0 MPa, the temperature is set to 120° C., and the sterilization time is set to 12 minutes.

[0062] The corn glutinous rice cake prepared through the above steps is golden in color, full of corn flavor, and has a shel...

Embodiment 2

[0064] (1) Peel the freshly picked sweet corn in the milk ripening stage, remove the beard and impurities, then clean it and manually thresh it.

[0065] (2) Use a pulverizer to pulverize the detached corn kernels into paste particles.

[0066] (3) Put the pulverized pasty particles into egg tart molds and steam them in a steamer. The steaming temperature is 120°C and the steaming time is 10 minutes.

[0067] (4) The steamed corn glutinous rice cake is placed in the packaging bag and vacuumized and sealed. The pumping speed of the vacuum pump used in the vacuum pumping process is 80m / h, and the pumping time is 20s.

[0068] (5) Put the packaged corn glutinous rice cakes into an autoclave, wherein the pressure of the sterilization process is set to 1.0 MPa, the temperature is set to 130° C., and the sterilization time is set to 20 minutes.

[0069] The corn glutinous rice cake prepared through the above steps has golden color, sweet taste and a shelf life of up to one year.

Embodiment 3

[0071] (1) Peel, remove beard and impurities from freshly picked waxy corn at milk maturity stage, then clean and manually thresh.

[0072] (2) Use a pulverizer to pulverize the detached corn kernels into paste particles.

[0073] (3) Put the pulverized pasty particles into egg tart molds and steam them in a steamer. The steaming temperature is 100°C and the steaming time is 8 minutes.

[0074] (4) Put the steamed corn glutinous rice cake into the packaging bag for vacuuming and sealing. In the vacuuming process, the pumping speed of the vacuum pump is 60m / h, and the pumping time is 18.5s.

[0075] (5) Put the packaged corn glutinous rice cake into an autoclave, wherein the pressure of the sterilization process is set to 1.4MPa, the temperature is set to 126°C, and the sterilization time is set to 16min.

[0076] The glutinous corn glutinous rice cake prepared through the above steps has a shelf life of up to one year, a golden color, a sweet taste, and is ready to eat after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com