Nutrition powder for improving flavor of granulated feed, preparation method thereof and production process of granulated feed containing the nutrition powder

A nutritional powder and granular feed technology, applied in animal feed, animal feed, application, etc., can solve problems such as insufficient stimulation, secretion of digestive juice, discounted gastrointestinal motility and feed intake, and low concentration of sweeteners. Achieve the effects of increased feed intake, increased bioavailability, and sufficient sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples.

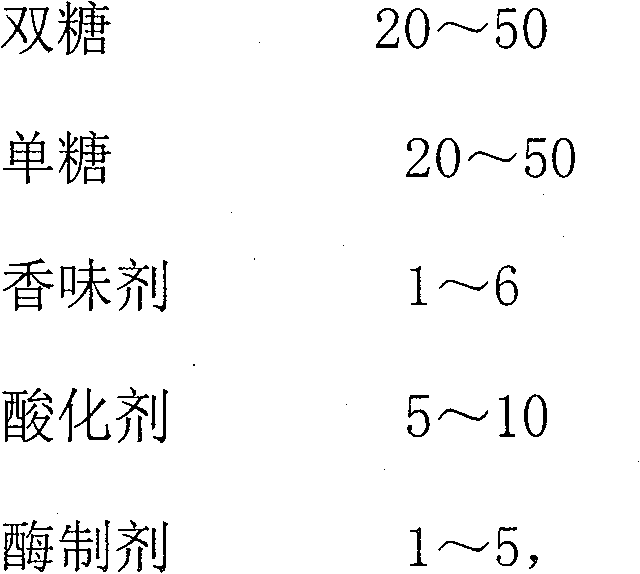

[0025] A nutritional powder for enhancing the flavor of granular feed, which consists of the following components in parts by weight:

[0026] Name of raw material Raw material (parts by weight) Name of raw material Raw material (parts by weight)

[0027] Disaccharides 45 Monosaccharides 40

[0028] Fragrance 5 Acidulant 7

[0029] Enzymes 3

[0030] The raw materials of the present invention can be purchased in the market, and the raw materials are simple and easy to obtain. In order to achieve the best effect, the raw materials can be prepared according to the needs.

[0031] Preferably, the complex enzyme includes phytase, cellulase and xylanase, phytase 5, cellulase 5 and xylanase 10 in parts by weight.

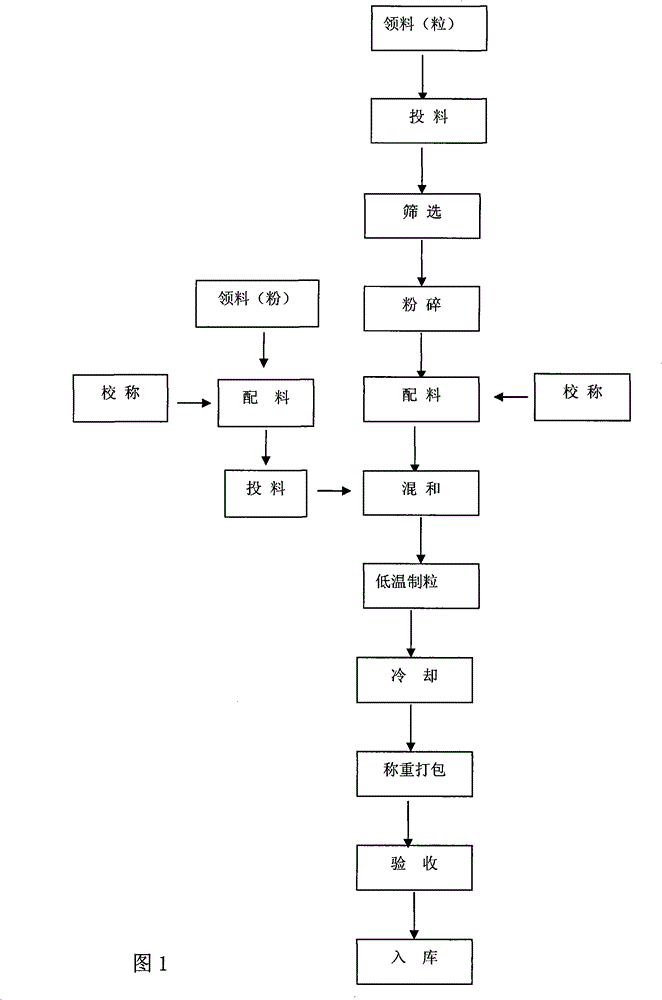

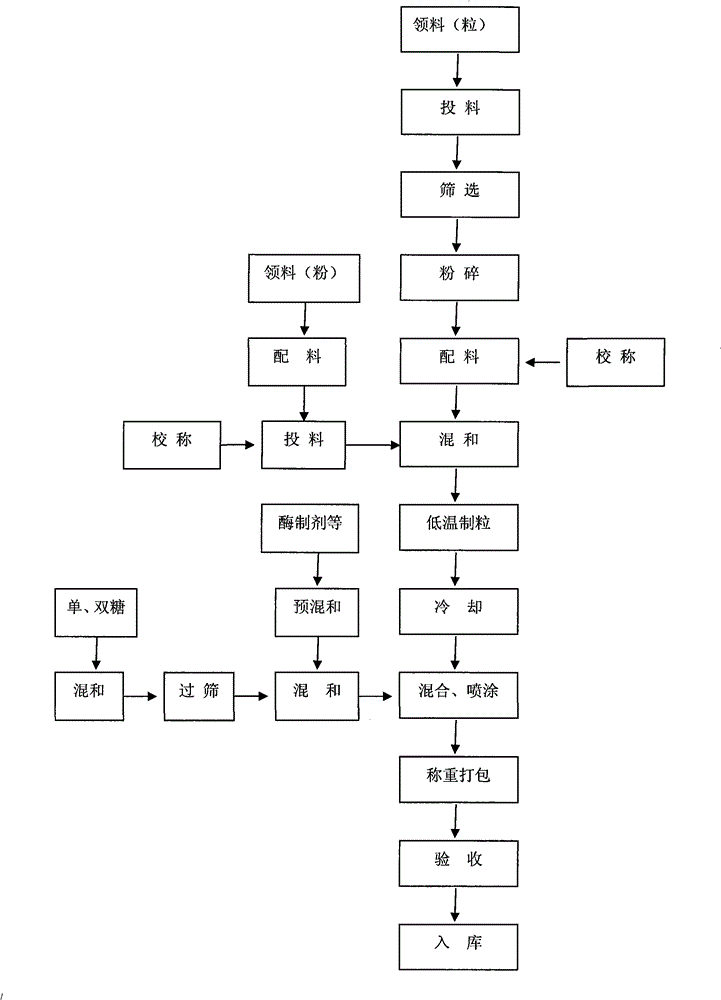

[0032] A kind of production method of the above-mentioned nutrient powder that improves the flavor of granular feed, its technical scheme comprises the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com