High flux rolled EDI assembly, assembly method thereof and desalting method

An assembly method and high-throughput technology, applied in separation methods, chemical instruments and methods, and general water supply conservation, etc., can solve problems such as component scrapping, water leakage of roll-type EDI components, and affecting the desalination effect of components, and achieve cost reduction and mitigation Scaling tendency, effect of reducing cost per ton of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

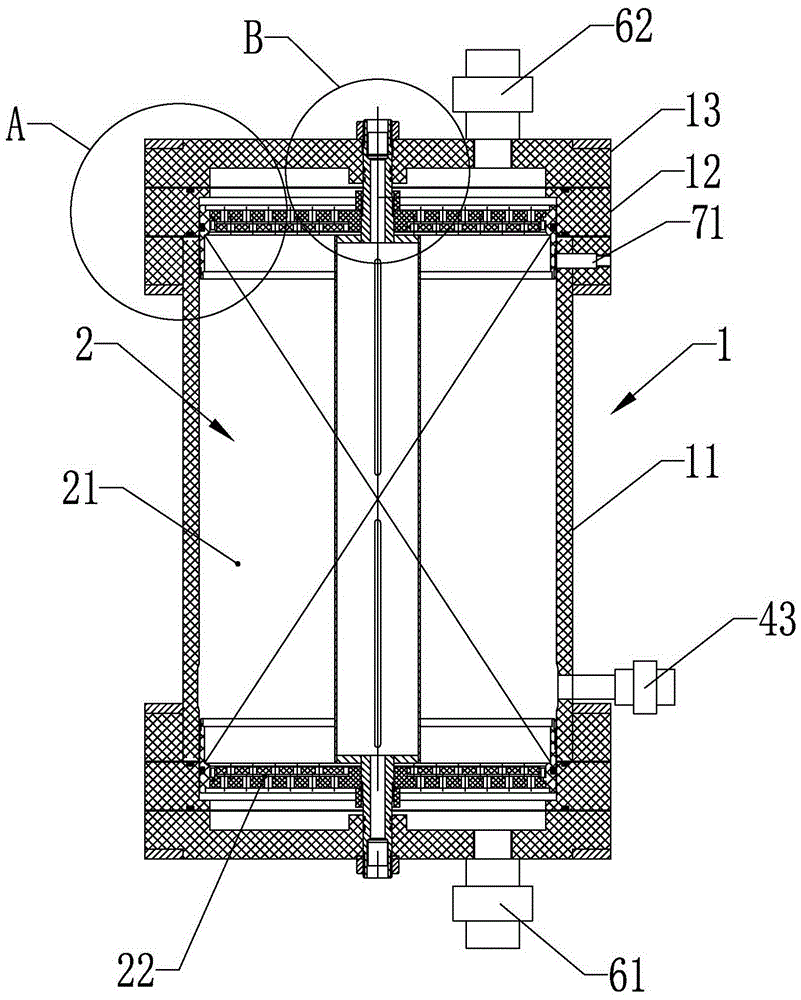

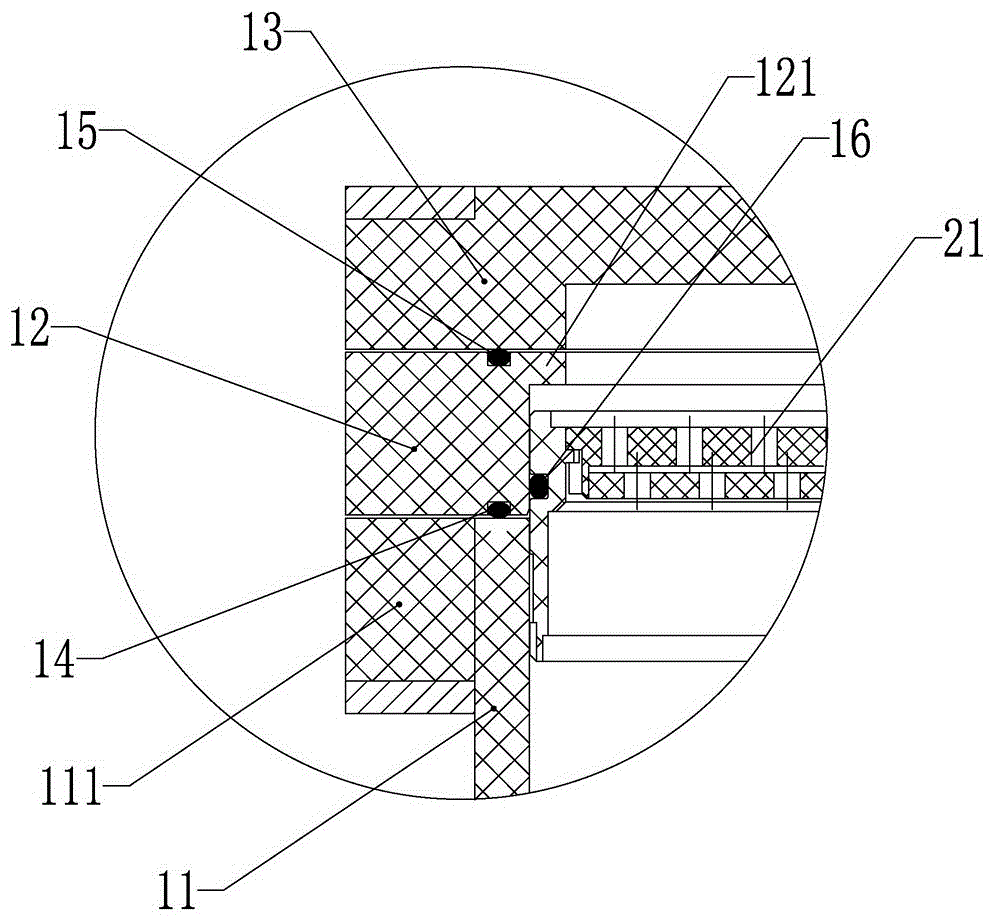

[0044] according to figure 1 , image 3 , Figure 4 As shown, a large-flux roll-type EDI assembly includes: a housing 1 and a membrane core 2. The housing 1 includes an outer shell 11, a sealing sleeve 12 and a cover plate 13. A sealing sleeve 12 and a cover plate 13 form a set Sealing structure, two ends of the outer shell 11 are respectively provided with a set of sealing structures, and the sealing sleeve 12 is arranged between the cover plate 13 and the end of the outer shell 11;

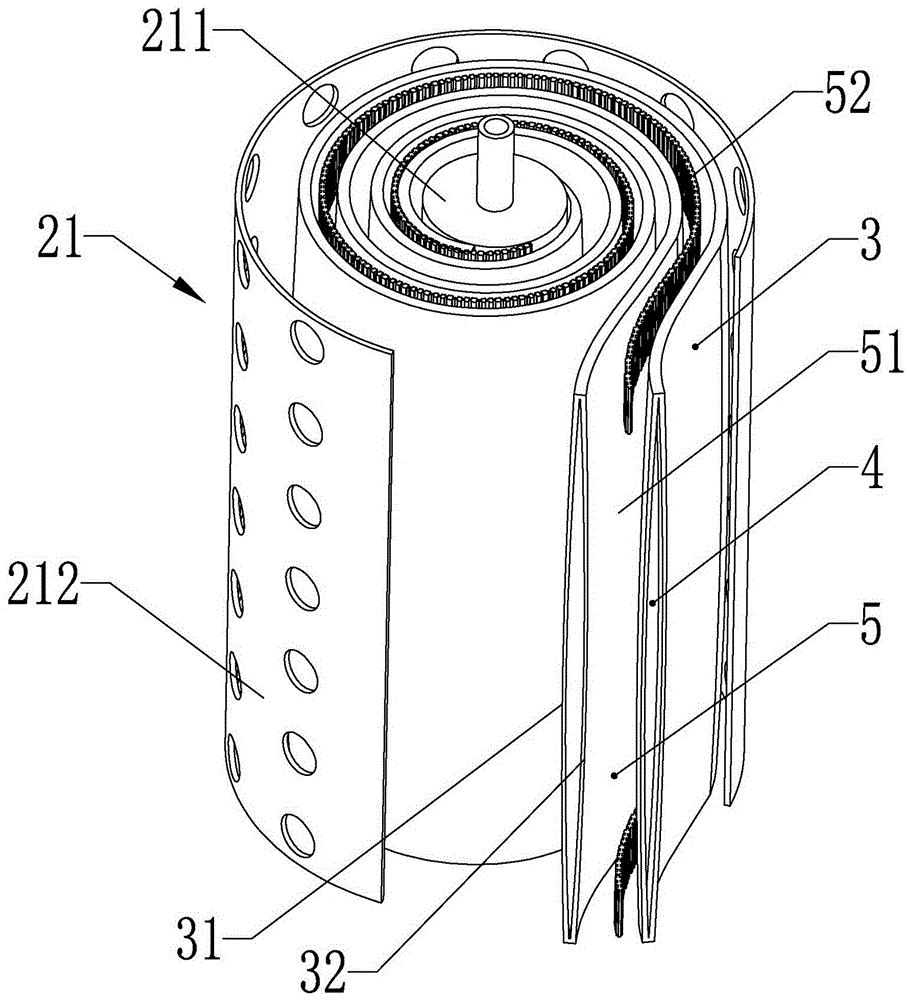

[0045] The membrane core 2 includes a core body 21 and an end cover 22. The core body 21 is set inside the outer shell 11, and the end cover 22 is sleeved inside the joint between the sealing sleeve 12 and the outer shell 11. The core body 21 includes seven sets of uniformly distributed The membrane unit 3.

[0046] A first sealing ring 14 is provided at the end of the sealing sleeve 12 and the outer shell 11 , a second sealing ring 15 is provided between the sealing sleeve 12 and the cover p...

Embodiment 2

[0051] The difference from the above-mentioned embodiment 1 is that, according to figure 2 As shown, the outer side of the core body 21 is covered with an anode cylinder 212, which can effectively ensure the stability of the anode electrification.

Embodiment 3

[0053] The method for assembling the large-volume roll-type EDI assembly of the above-mentioned embodiment 1 comprises the following steps:

[0054] A Assemble the membrane core 2, attach the positive membrane 31 and the negative membrane 32 to form the membrane unit 3, wind multiple sets of membrane units 3 onto the cathode column 211, and line the grid plate 52 between the membrane units 3 during winding, After the winding is completed, assemble the anode cylinder 212 to the outside of the core body 21;

[0055] B Assemble the shell, ① Put the membrane core 2 into the outer shell 11, and then insert the end cap 22 at both ends of the membrane core 2, the end cap 22 is partially inserted into the inside of the outer shell 11, and the two ends of the membrane core 2 are inserted into the end cap At 22 o'clock, put the fourth sealing ring 17 in the first outlet 42 and the cover plate 13; The end is equipped with a first sealing ring 14 and a second sealing ring 15; ③ buckle th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com