Chemical mechanical grinding device and method

A chemical machinery and grinding device technology, applied in grinding devices, abrasive surface adjustment devices, grinding machine tools, etc., can solve problems such as separation of new and old grinding fluids, reduce usage, improve grinding efficiency and quality, and improve uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

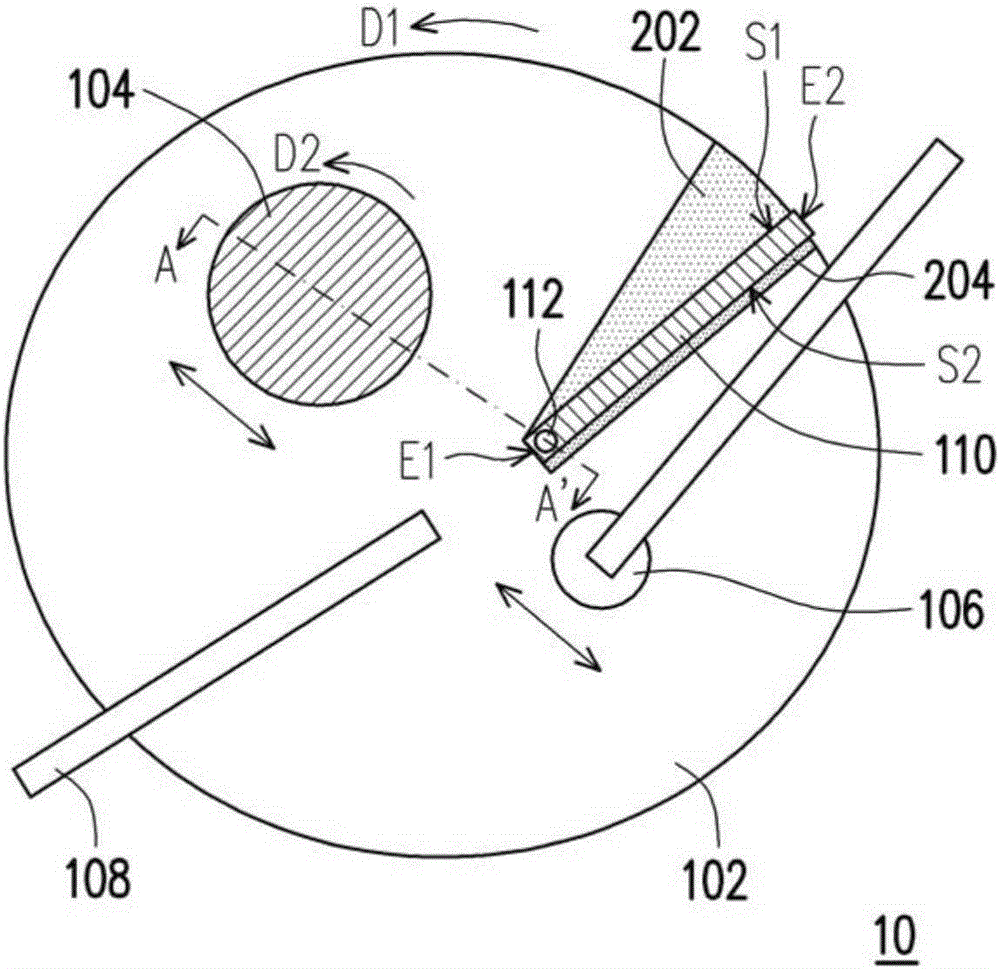

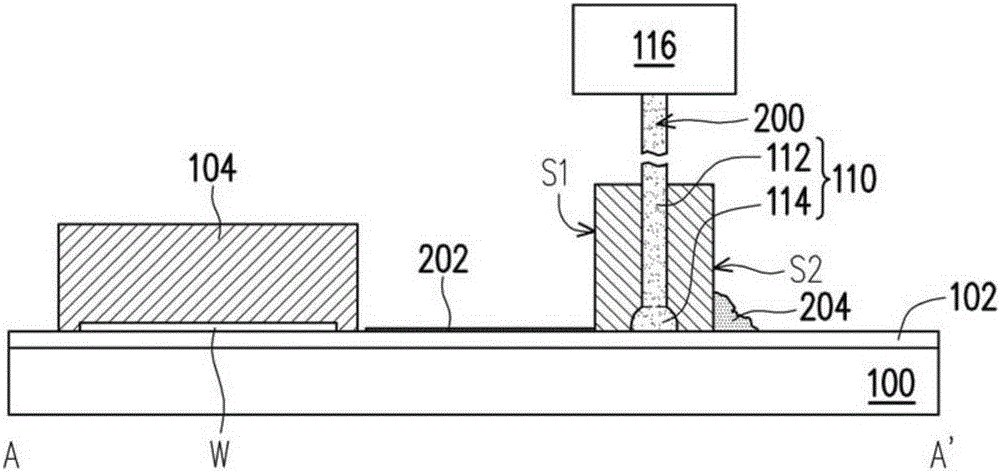

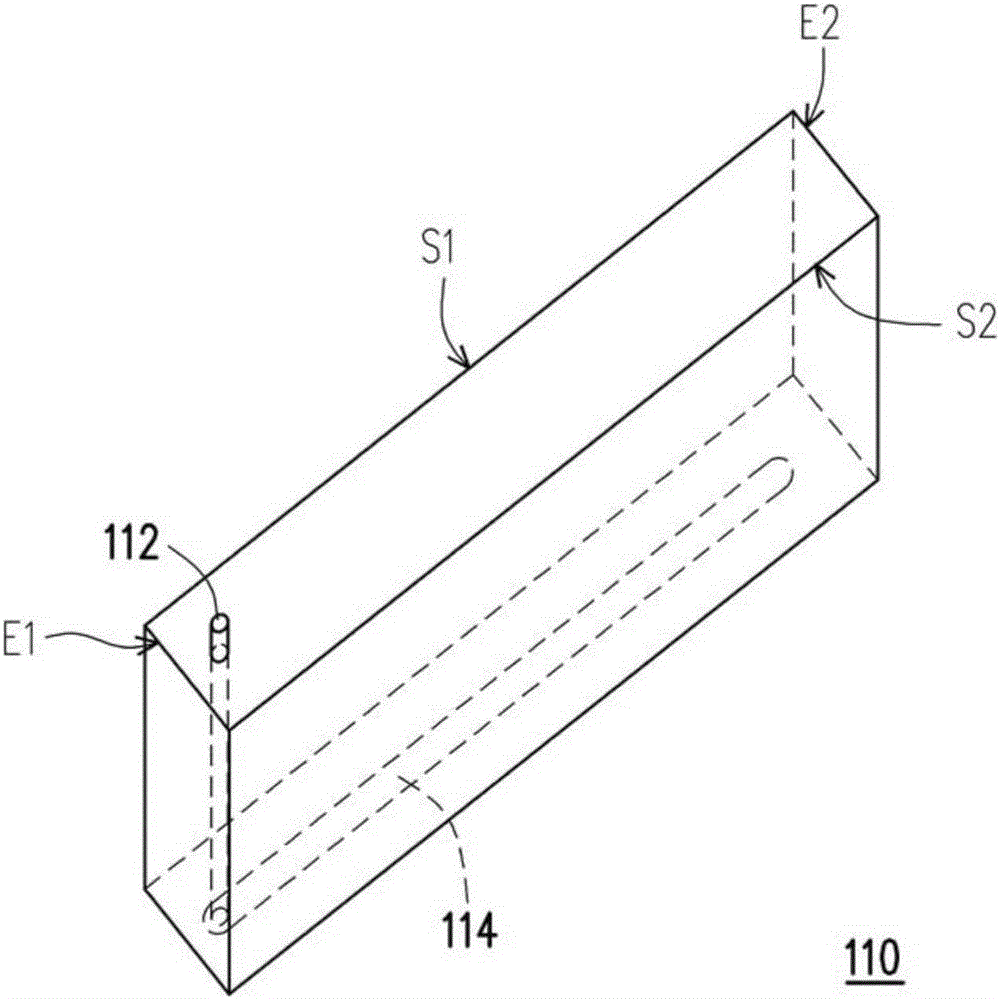

[0041] figure 1 It is a schematic top view of a chemical mechanical polishing device according to an embodiment of the present invention. figure 2 for figure 1 A schematic cross-sectional view of line A-A'. image 3 for figure 1 Schematic perspective view of the separator. Figure 4 for image 3 A schematic perspective view of the second surface of .

[0042] Please refer to figure 1 and figure 2 , the present embodiment provides a chemical mechanical polishing device 10 comprising: a polishing table 100 , a polishing pad 102 , a polishing head 104 , a regulator 106 , a polishing liquid supply device 116 and a separator 110 . The polishing pad 102 is disposed on the polishing table 100 for polishing the wafer W. The polishing table 100 drives the polishing pad 102 to rotate along the first direction D1 through a rotating shaft (not shown), and is equipped with various polishing liquids to planarize the wafer W or semiconductor manufacturing process. Structure, chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com