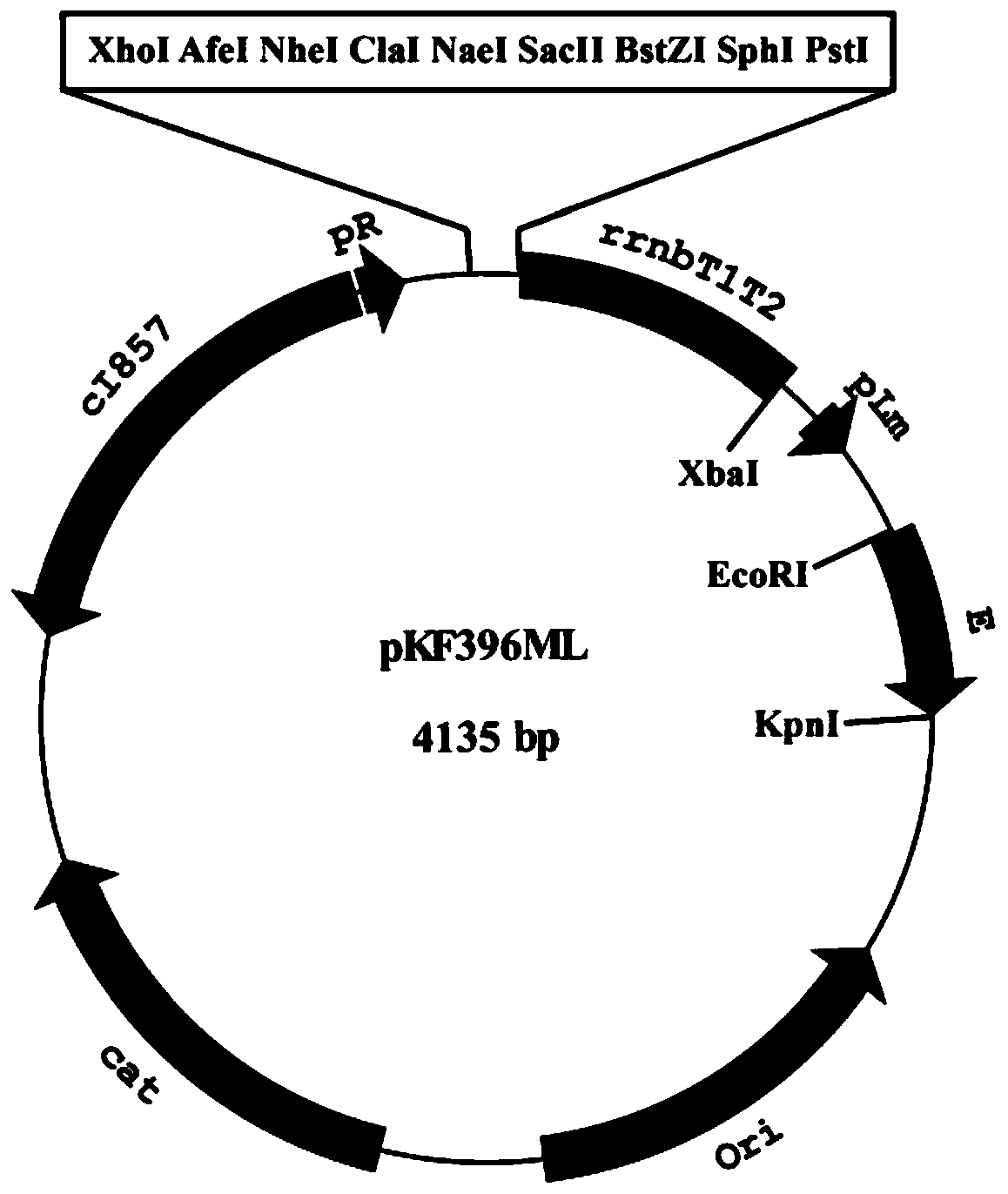

A thermally stable temperature-controlled pyrolysis system based on λci857/pl and its construction method and application

A construction method and technology for cleavage genes, applied in the field of thermally stable temperature-controlled lysis systems, can solve the problems of efficient preparation of unfavorable sloughs, large plasmid volume, and heavy screening tasks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

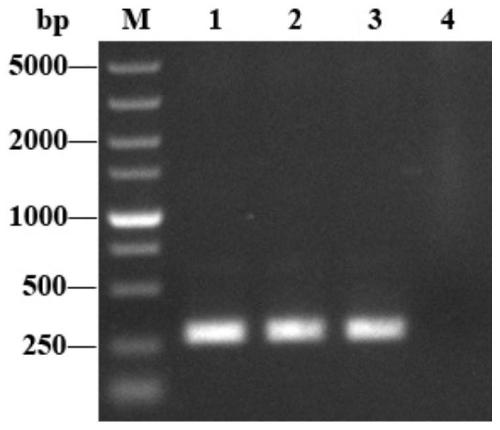

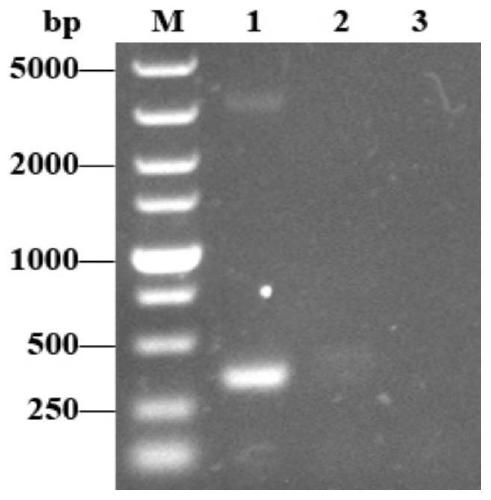

Examples

Embodiment Construction

[0035] In the following examples, various processes and methods not described in detail are conventional methods well known in the art. Meanwhile, the terms used in the present invention generally have the meanings commonly understood by those skilled in the art unless otherwise specified.

[0036] (1) Experimental materials

[0037] 1. Strains and Plasmids

[0038] Escherichia coli DH5α chemically competent cells were purchased from Nanjing Nuoweizan Biotechnology Co., Ltd. (Product No.: C502-02), and E. coli mutant strain ES1578 (CGSC#: 6485) was purchased from Yale University E. coli Genetic Stock Center) courtesy of Dr. Narinder Whitehead. Plasmids pBV220-E, pKF396M-5 were constructed and preserved by this experiment (Fu LX, Lu.CP.A Novel Dual Vector CoexpressingPhiX174Lysis E Gene and Staphylococcal Nuclease A Gene on the Basis of LambdaPromoter pR and pL, Respectively. Mol Biotechnol, 2013, 54( 2): 436-444).

[0039] 2. Main reagents

[0040] Restriction enzyme EcoR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com