Cationic dyeable polyurethane elastic fiber and preparation method thereof

A polyurethane elastic and cationic technology, applied in fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problems of less research on coloring properties, achieve bright color, reduce energy consumption, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

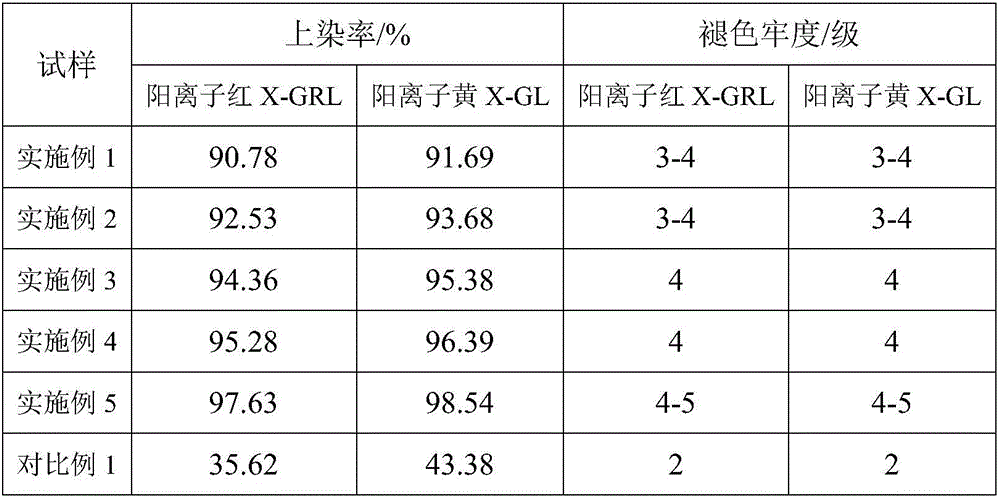

Embodiment 1

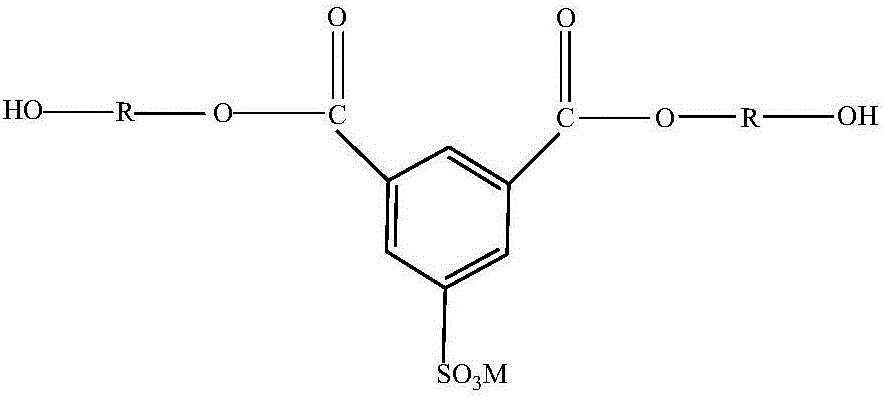

[0026] (1) Combine polytetrahydrofuran ether glycol PTMG (molecular weight 1810) 375.95Kg, small molecule sulfonate-based diol 0.451Kg (sodium dimethyl isophthalate-5-sulfonate and 1,4-butanediol The reactant is equivalent to 1Kg PTMG containing 1200ppm of small molecule sulfonate-based diol) and 87.95Kg of diphenylmethane-4,4'diisocyanate are placed in the reactor and reacted at 86±2℃ for 120min, Obtain an isocyanate group-terminated prepolymer;

[0027] (2) Add 692.8Kg of DMAC to the prepolymer to fully dissolve the prepolymer in DMAC;

[0028] (3) Add to the prepolymer solution an amine mixed solution formed by dissolving 7.841Kg ethylenediamine, 0.509Kg propylenediamine, and 1.522Kg diethylamine in 187.567Kg DMAC to carry out chain extension reaction and chain termination reaction , Get polyurethane urea stock solution;

[0029] (4) Adding matting agent, anti-yellowing agent, ultraviolet absorber, antioxidant and lubricating and relaxing agent to polyurethane urea stock solutio...

Embodiment 2

[0032] The preparation method is the same as in Example 1, the difference is that every 1 Kg of PTMG contains 3500 ppm of small molecule sulfonate-based diol.

Embodiment 3

[0034] The preparation method is the same as that in Example 1, except that every 1 Kg of PTMG contains 7500 ppm of small molecule sulfonate-based diol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com