Method for processing anti-aging, cold-resistant, antibacterial and high-moisture-penetrability raincoat fabric

A processing method and anti-aging technology, applied in the direction of biochemical fiber treatment, liquid-repellent fibers, fiber types, etc., can solve the problems of high moisture permeability, high water pressure, and non-environmental protection, and achieve environmental protection of fabrics, convenient operation, Good effect of cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

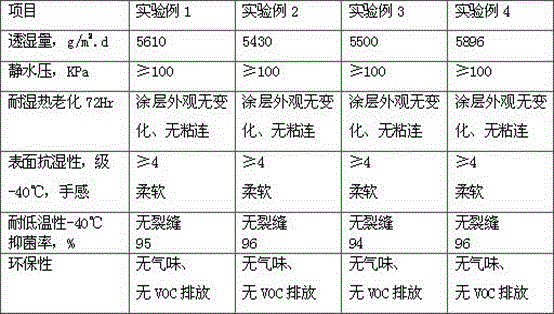

Examples

Embodiment 1

[0039] 1) Preparation of coating glue

[0040] A. Preparation of bottom coating glue:

[0041] Water-based waterproof and high moisture-permeable polyurethane adhesive 100, anionic or nonionic fluorine-based waterproofing agent 5, hydroxyl-terminated polydimethylsiloxane emulsion 5, polymethylurea resin 3, mix and stir evenly, and then add appropriate amount of water to adjust The viscosity is at 10000mPa.s, and the bottom coating glue is obtained.

[0042] B. Preparation of surface coating glue:

[0043] Water-based polyurethane adhesive 100, microporous lignocellulose 5 with d=30 μm, and antibacterial and deodorant finishing agent 6 are mixed and stirred evenly, then add isocyanate crosslinking agent 1, and add an appropriate amount of water to adjust the viscosity at 7000mPa.s to obtain a top coat layer glue.

[0044] 2) Pre-treatment of the base fabric: Water-repellent treatment is carried out on polyester, nylon and polyester-nylon blended fabrics.

[0045] 3) Fabric pr...

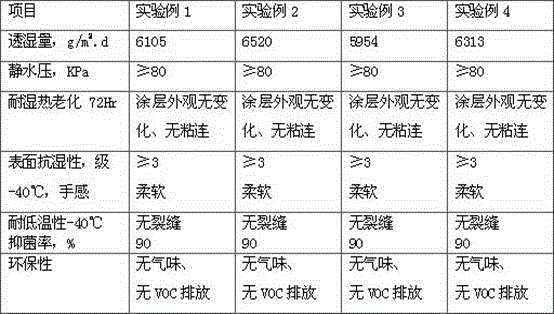

Embodiment 2

[0049] 1) Preparation of coating glue

[0050] A. Preparation of bottom coating glue:

[0051] Water-based waterproof and high moisture-permeable polyurethane adhesive 100, anionic or nonionic fluorine-based waterproofing agent 7, hydroxyl-terminated polydimethylsiloxane emulsion 6, polymethylurea resin 4, mix and stir evenly, and then add appropriate amount of water to adjust The viscosity is at 12000mPa.s, and the bottom coating glue is obtained.

[0052] B. Preparation of surface coating glue:

[0053] Water-based polyurethane adhesive 100, microporous lignocellulose 6 with d=30 μm, and antibacterial and deodorant finishing agent 7 are mixed and stirred evenly, then add isocyanate crosslinking agent 2, add an appropriate amount of water to adjust the viscosity at 7300mPa.s, and obtain the surface coating layer glue.

[0054] 2) Pre-treatment of the base fabric: Water-repellent treatment is carried out on polyester, nylon and polyester-nylon blended fabrics.

[0055] 3) ...

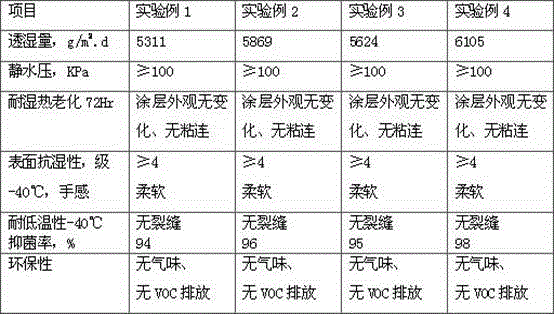

Embodiment 3

[0059] 1) Preparation of coating glue

[0060] A. Preparation of bottom coating glue:

[0061] Water-based waterproof and high moisture-permeable polyurethane adhesive 100, anionic or nonionic fluorine-based waterproofing agent 8, hydroxyl-terminated polydimethylsiloxane emulsion 7, polymethylurea resin 3, mix and stir evenly, and then add appropriate amount of water to adjust The viscosity is at 13000mPa.s, and the bottom coating glue is obtained.

[0062] B. Preparation of surface coating glue:

[0063] Water-based polyurethane adhesive 100, microporous lignocellulose 8 with d=15 μm, and antibacterial and deodorant finishing agent 7 are mixed and stirred evenly, then add isocyanate crosslinking agent 2.5, add an appropriate amount of water to adjust the viscosity at 7500mPa.s, and obtain the top coat layer glue.

[0064] 2) Pre-treatment of the base fabric: Water-repellent treatment is carried out on polyester, nylon and polyester-nylon blended fabrics.

[0065] 3) Fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com