Stranding machine

A technology for making a stranding machine and a frame, which is used in textiles, papermaking, textile cables, etc., can solve the problems of complex structure, single function, unstable operation, etc., and achieve the effect of stable operation and simple operation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

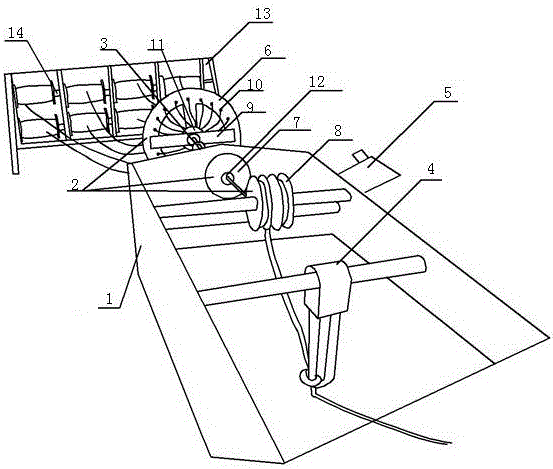

[0011] A strand making machine, comprising a frame 1, a twisting and plying device 2 arranged on the frame 1, a pulley 3, a winding device 4 and a motor 5, the twisting and plying device 2 is composed of a carrier plate 6, a crimping wheel 7 and a ply wheel 8, the carrier plate 6 is provided with a fixed column 9 and a conductor coil 10, the other end of the frame 1 is provided with a twister 11, and the crimping wheel 7 is horizontally arranged on the frame 1 , one end of the crimping wheel 7 is horizontally provided with a main shaft 12, the motor 5 drives the rotating main shaft 12, and the twister 11 is connected with the transmission of the main shaft 12; one end of the twisting and plying device 2 is provided with at least Ten groups of lead frames 13 are provided with lead rolls 14 arranged on the lead frames 13 , and the lead rolls 14 are neatly distributed along the vertical direction of the lead frame 1 . The motor 5 is a frequency conversion speed regulating device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com