Plunger gas recovery device capable of achieving continuous production of gas well without well shutdown

A technology of plunger and gas recovery, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of long working cycle, complicated ground control mechanism, and large falling resistance, and achieves simple structure and ingenious design , easy to disassemble and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

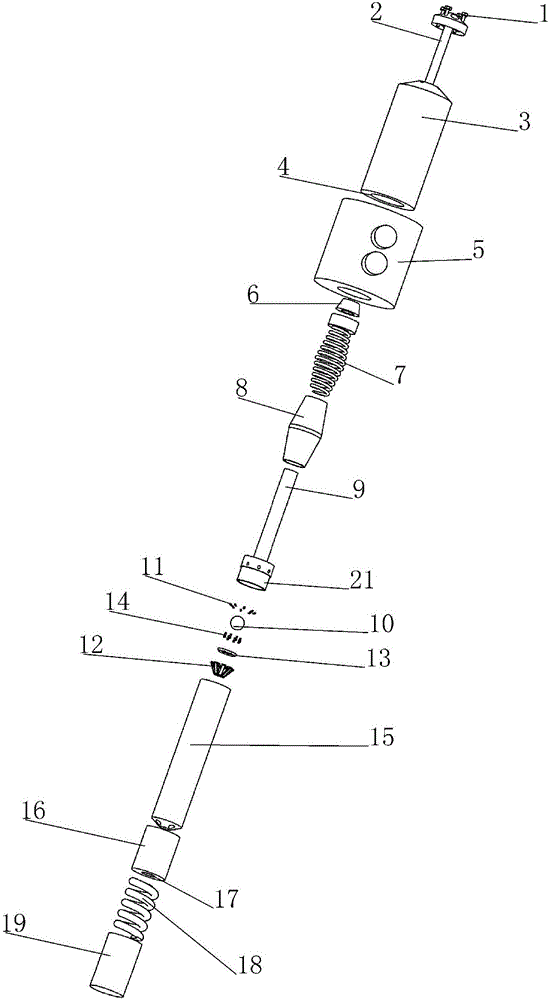

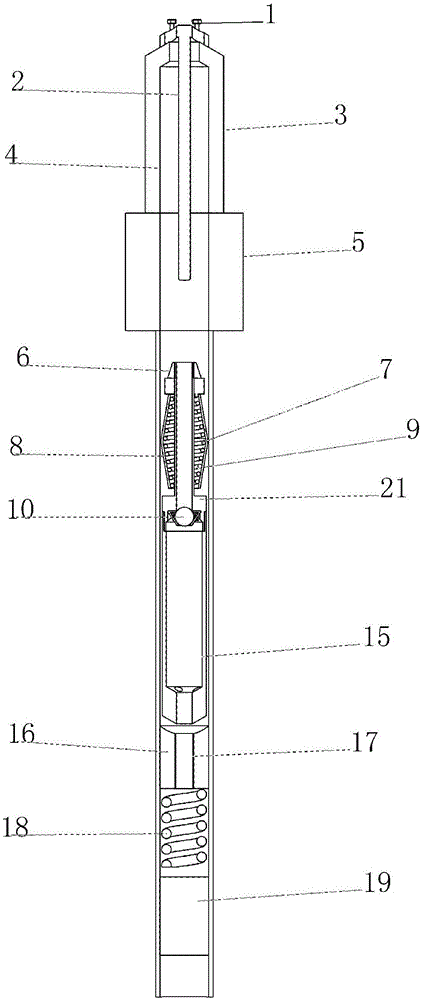

[0038] Depend on Figure 1 to Figure 21 As shown, this kind of plunger gas production device that can realize the continuous production of gas wells without shutting down the wells includes tubing 3, casing 4, blowout preventer 5 and setter 19. Casing 4 is located in tubing 3, and the An annular gap is left, and the blowout preventer 5 is connected to the upper end of the oil pipe 3 and the casing 4, and the seater 19 is located at the bottom of the casing 4. Its unique features are:

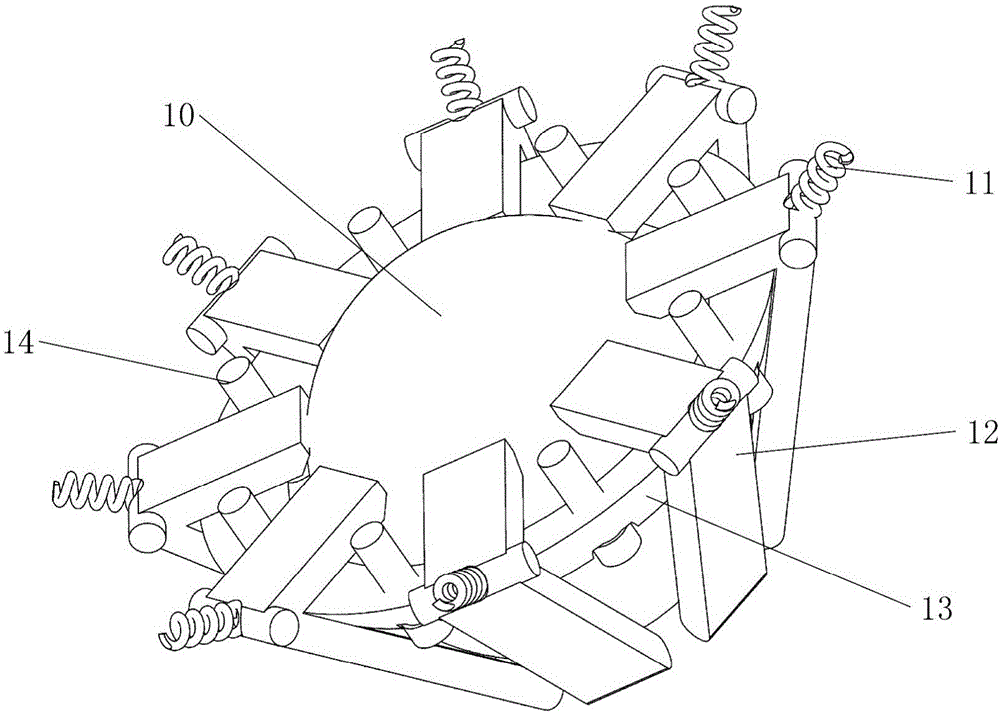

[0039] The plunger gas extraction device also includes a push rod 2 located in the casing 4, an upper plunger body 21 with an upper plunger body hollow shaft 9, a special-shaped spring fixing device 6, a special-shaped spring 7, a special-shaped spring rubber sleeve 8, Steel ball 10, small ball fixing splint 12, splint supporting spring 11, splint fixing ring 13 and fixing ring supporting bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com