Efficient and energy-saving experimental temperature adjustment system and work method thereof

A technology of temperature adjustment, high efficiency and energy saving, which is applied to the operation mode of the machine, the compression machine with irreversible cycle, the compression machine with reversible cycle, etc., which can solve the problem of slow temperature and test water temperature adjustment speed, slow temperature adjustment speed, and slow temperature cooling and other problems, to achieve the effect of reducing experimental test time, heat recovery and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiment:

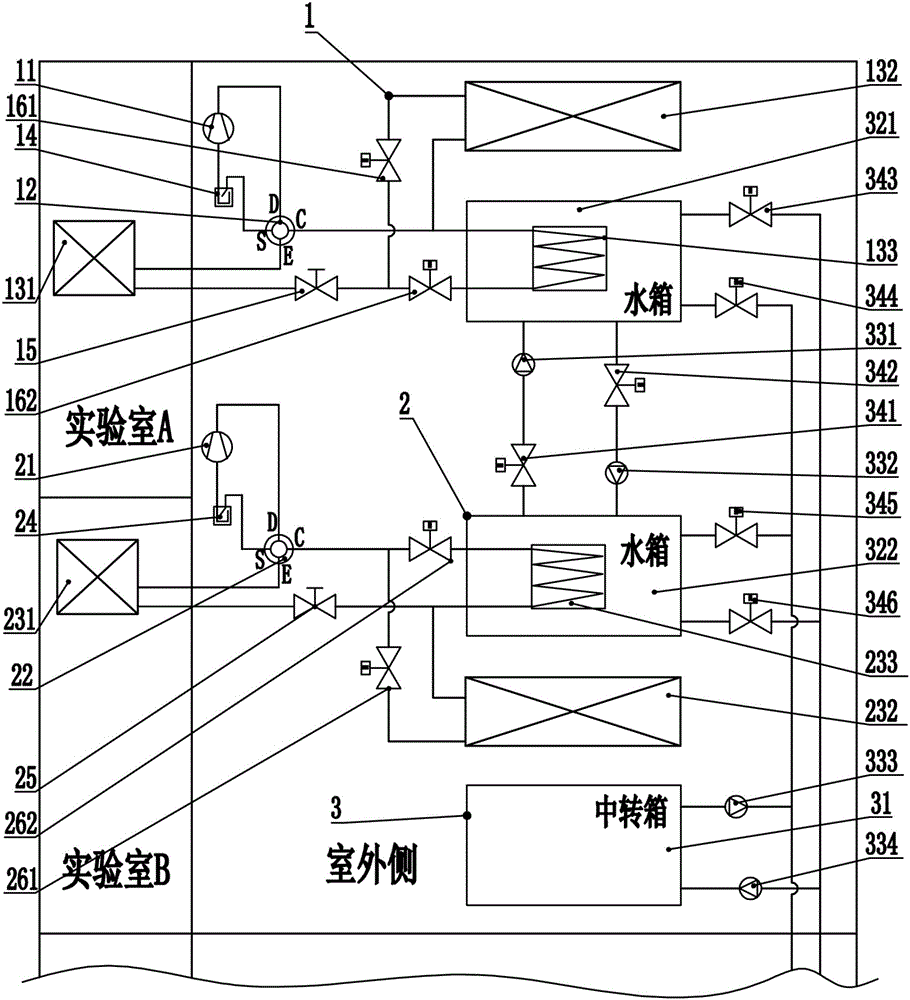

[0020] See attached figure 1 As shown, a high-efficiency and energy-saving experimental temperature adjustment system and its working method include a first refrigeration system 1, a second refrigeration system 2 and an energy storage system 3, wherein the first refrigeration system 1 includes a first compressor 11, a first Four-way valve 12, first heat exchanger 131, second heat exchanger 132, third heat exchanger 133, first gas-liquid separator 14, first throttle member 15, first cut-off valve 161 and second cut-off valve valve 162, the first four-way valve 12 is provided with four ports C, D, E, and S; the second refrigeration system 2 includes a second compressor 21, a second four-way valve 22, a fourth heat exchanger 231, and a fifth Heat exchanger 232, sixth heat exchanger 233, second gas-liquid separator 24, second throttle member 25, third stop valve 261 and fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com