Method for detecting dynamic modulus of each layer of asphalt pavement and adhesion device

A technology for asphalt pavement and dynamic detection, which is applied in the direction of measuring devices, application of repeated force/pulsation force to test material strength, instruments, etc., can solve the problem that asphalt pavement cannot be stratified in the south, and achieve the effect of low equipment transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The dynamic detection method for each layer of asphalt pavement in this embodiment comprises the following steps:

[0048] (1) Specimen preparation: Drill the core on the road to take a 150mm diameter specimen, drill a core sample with a diameter of 100mm in the room, and then use a double-sided saw to cut off each layer of mixture and store it in an environment of 5-27°C , the time should not exceed two weeks;

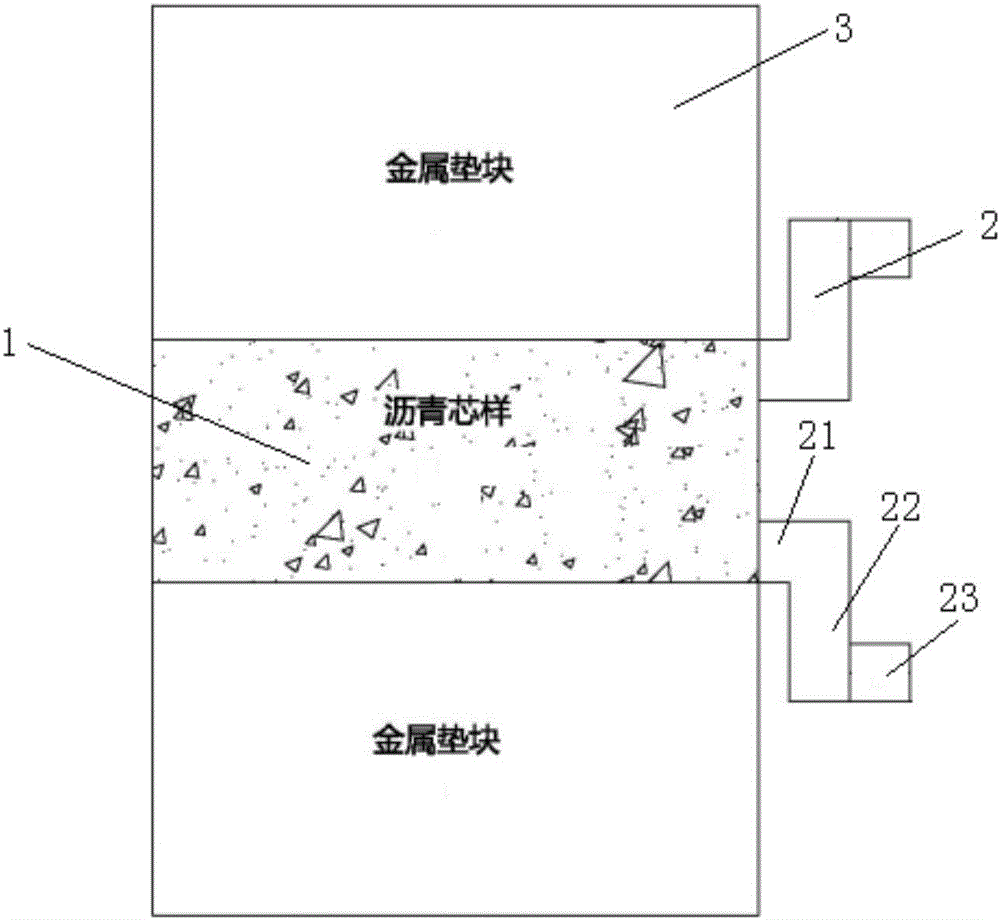

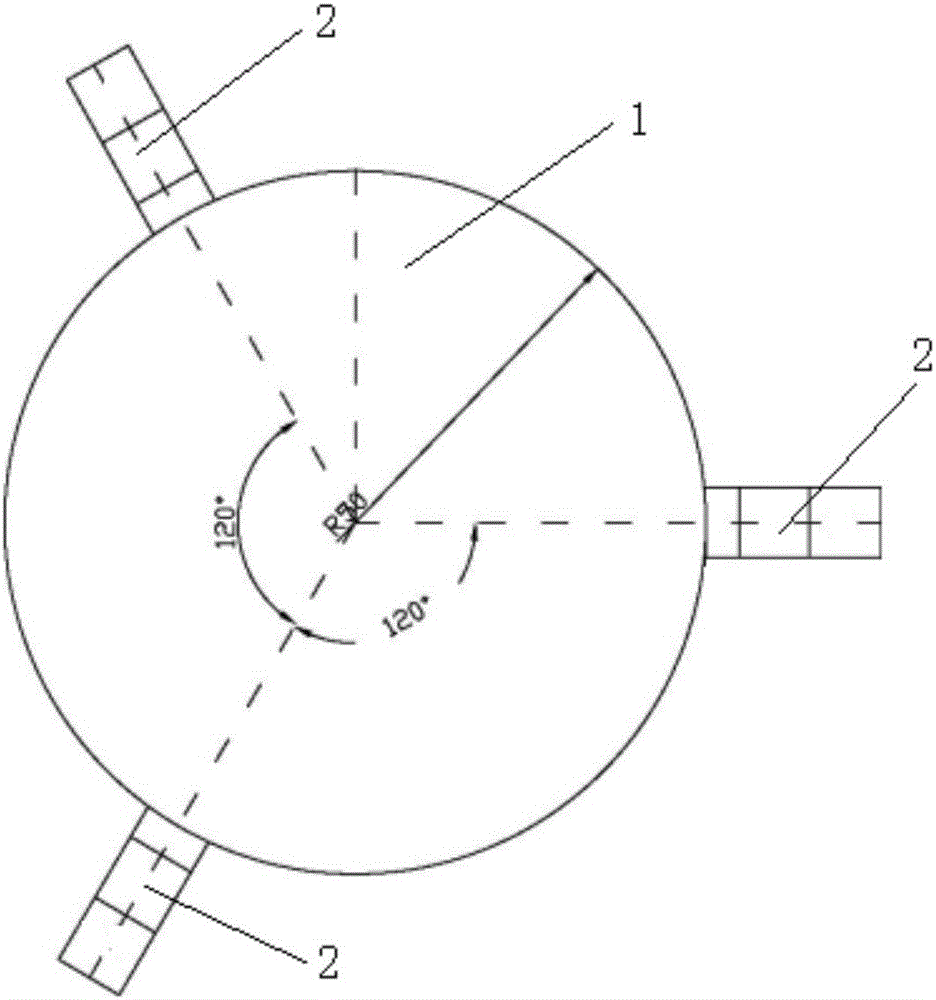

[0049] (2) Paste the Velcro: First, manually attach 6 L-shaped custom-made Velcro (see attached image 3 ) around the core sample, and arrange 3 rows of 6 at equal intervals along the circumference (that is, every 2 rows are 120° apart). Fix the second sticky fasteners on the 6 first sticky buttons with special equipment for sticking sticky buckles, and then place the displacement sensor between each row of sticky buckles so that it is perpendicular to the end face of the test piece, and adjust the displacement sensor so that the measuring range Can measure t...

Embodiment 2

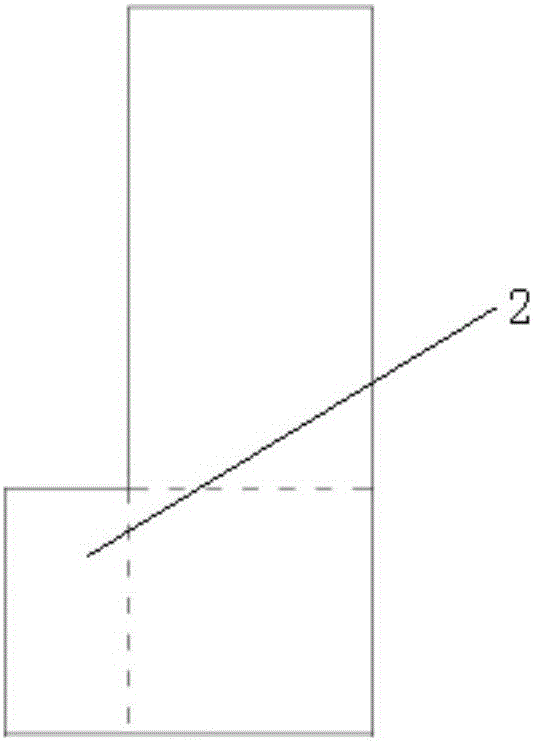

[0070] The fastening device of this embodiment is the fastening device used in the dynamic detection method for each layer of asphalt pavement asphalt pavement described in the above-mentioned embodiment 1, and the fastening device is composed of a first fastening fastening and a second fastening fastening, The first Velcro is composed of a horizontal block and a vertical block connected to each other, one end of the horizontal block is connected to the core sample, and the other end is connected to the vertical block, and the second Velcro is a Cubic block structure, the second sticky fastener is connected to the vertical block. The fastening device of this embodiment is an L-shaped structure, see Figures 3 to 5 shown.

[0071] In this embodiment, the cube fastener is pasted on the vertical block by glue. The horizontal block and the vertical block are integrally structured.

[0072] When in use, stick 6 first sticky buttons around the core sample by hand, place 3 rows of...

Embodiment 3

[0074] The fastening device of this embodiment differs from the above-mentioned embodiment 2 only in that the fastening device has a T-shaped structure, see Image 6 .

[0075] In each of the above embodiments, the fastening device is arranged on the cylindrical surface of the core sample, at a position between the distance to the upper surface of 1 / 6 of the height of the core sample and the distance to the lower surface of 1 / 6 of the height of the core sample.

[0076] In each of the above-mentioned embodiments, in order to better realize the connection between the horizontal block and the core sample, the end surface pasted between the horizontal block and the core sample has an arc surface structure, and the structure of the arc surface is consistent with the circle of the core sample. Compatible with curved surfaces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness dimension | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com