E-shaped silicon steel sheet and rolling method therefor

A technology of silicon steel sheet and rolling force, applied in the field of silicon steel sheet, E-type silicon steel sheet and its rolling, can solve the problem that it cannot meet the increasingly high requirements of the stator of wind turbines, and can not make good use of materials and silicon steel sheets. The problem of high iron loss value can achieve good economic and social benefits, improve magnetic properties, and reduce iron loss value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

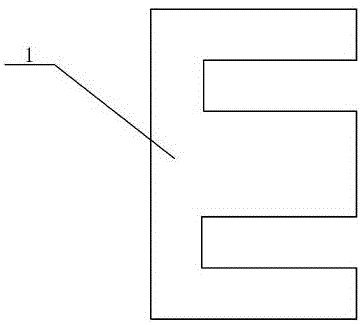

[0020] see figure 1 , the present invention relates to an E-type silicon steel sheet, which includes a silicon steel sheet body 1, the silicon steel sheet body 1 is E-shaped, and the chemical composition of the silicon steel sheet is: C 0.04~0.05wt%, Si 3.20~3.80wt%, Mn 0.06 ~0.07wt%, P 0.010~0.017wt%, S 0.004~0.005wt%, Sn 0.08~0.128wt%, Cu 0.10~0.15wt%, Al 0.05~0.06wt%, and the rest is Fe.

[0021] A rolling method of an E-type silicon steel sheet, the rolling steps of the method are:

[0022] 1) The first rolling pass:

[0023] The silicon steel sheet to be rolled is rolled in the first pass at room temperature by using a 16-roll mill. The mechanical parameters of the first pass are: the left tension is 1.665~1.865KN, the right tension is 2.156~2.356KN, The rolling force is 293.920~303.920KN, and the thickness of the silicon steel sheet after the first rolling is 0.075~0.095mm;

[0024] 2) The second rolling pass:

[0025] The silicon steel sheet rolled in the first pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com