Aeration and medicine throwing all-in-one machine for fishpond

An all-in-one machine and drug technology, applied in applications, fish farming, motor vehicles, etc., can solve the problems of short service life of the hull, restricting the development of fishery, and short service life, so as to simplify equipment, improve anti-corrosion effect, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

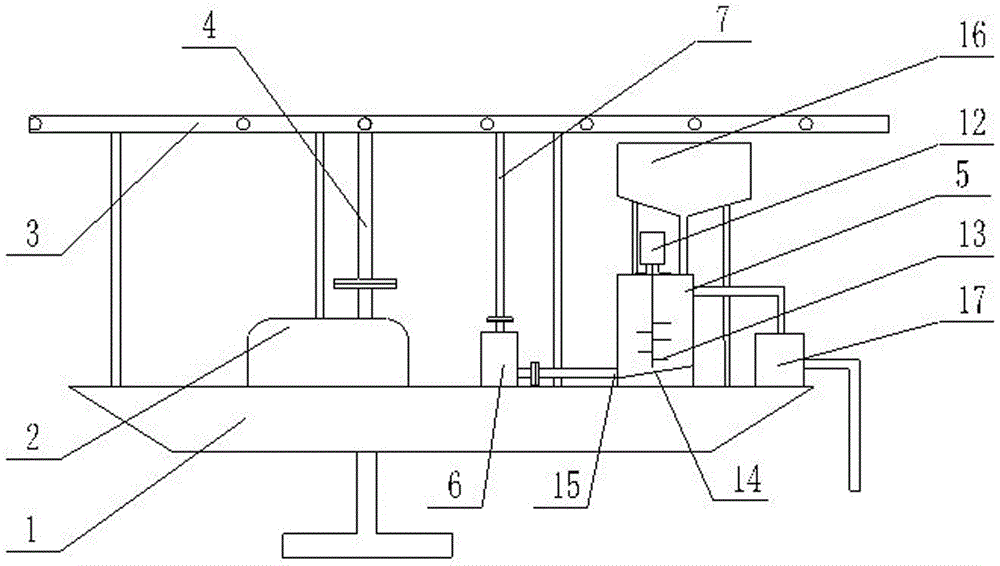

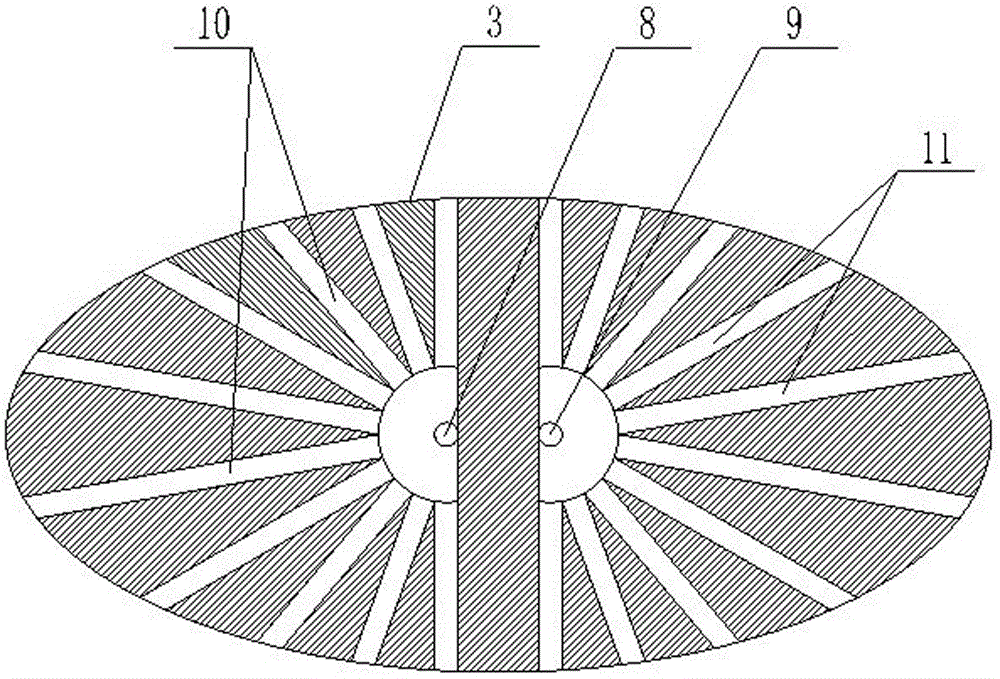

[0029]This embodiment provides an all-in-one machine for spraying oxygen-increasing medicines for fish ponds, including a hull 1, the upper end of the hull 1 is sequentially provided with a water suction pump 2, a second water pump 6 and a tank body 5 along its length direction, and the input end of the water suction pump 2 is worn Pass the hull 1 and extend into the water. An aeration plate 3 is arranged above the water suction pump 2. The aeration plate 3 is connected to the output end of the water suction pump 2 through a connecting pipe 4. The input end of the second water pump 6 is connected to the tank body 5. The second water pump The output port of 6 is provided with branch pipe 7, and branch pipe 7 is connected with aeration plate 3, and aeration plate 3 is elliptical, and aeration plate 3 is provided with the first inlet 8 that is connected with connecting pipe 4 and the first inlet 8 that is connected with branch pipe 7. Two inlets 9, the aeration plate 3 is provided...

Embodiment 2

[0039] This embodiment provides an all-in-one machine for sprinkling oxygen-increasing medicines for fish ponds. The structure is exactly the same as that in Embodiment 1, wherein the outer surface of the hull 1 is coated with a corrosion-resistant metal coating, and the composition of the corrosion-resistant metal coating is By mass percentage: C: 0.05%, Mn: 0.18%, Cr: 4.79%, Ni: 0.15%, Cu: 0.25%, Mo: 0.65%, W: 0.15%, V: 0.28%, Al: 0.20%, Ti: 0.15%, B: 0:050%, S: 0.001%, P: 0.002%, the balance is Fe;

[0040] The treatment process of corrosion-resistant metal coating is carried out in the following steps:

[0041] Step 1: Put C, Mn, Cr, Ni, Cu, Mo, W, V, Al, Ti, B, S, P and Fe into the smelting furnace, increase the temperature to 560°C, keep it for 3 hours, and then Increase the temperature to 1480°C, keep it warm for 4 hours, then use air cooling, cool to 534°C at a cooling rate of 17°C / s, and then air cool to room temperature to obtain a metal body;

[0042] Step 2: Put ...

Embodiment 3

[0047] This embodiment provides an all-in-one machine for sprinkling oxygen-increasing medicines for fish ponds. The structure is exactly the same as that in Embodiment 1, wherein the outer surface of the hull 1 is coated with a corrosion-resistant metal coating, and the composition of the corrosion-resistant metal coating is By mass percentage: C: 0.04%, Mn: 0.17%, Cr: 4.78%, Ni: 0.13%, Cu: 0.24%, Mo: 0.63%, W: 0.14%, V: 0.27%, Al: 0.19%, Ti: 0.14%, B: 0030%, S: 0.0008%, P: 0.001%, the balance is Fe;

[0048] The treatment process of corrosion-resistant metal coating is carried out in the following steps:

[0049] Step 1: Put C, Mn, Cr, Ni, Cu, Mo, W, V, Al, Ti, B, S, P and Fe into the smelting furnace, increase the temperature to 558°C, keep it for 2 hours, and then Increase the temperature to 1470°C, keep it warm for 3 hours, then use air cooling to cool to 532°C at a cooling rate of 16°C / s, and then air cool to room temperature to obtain a metal body;

[0050] Step 2: Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com