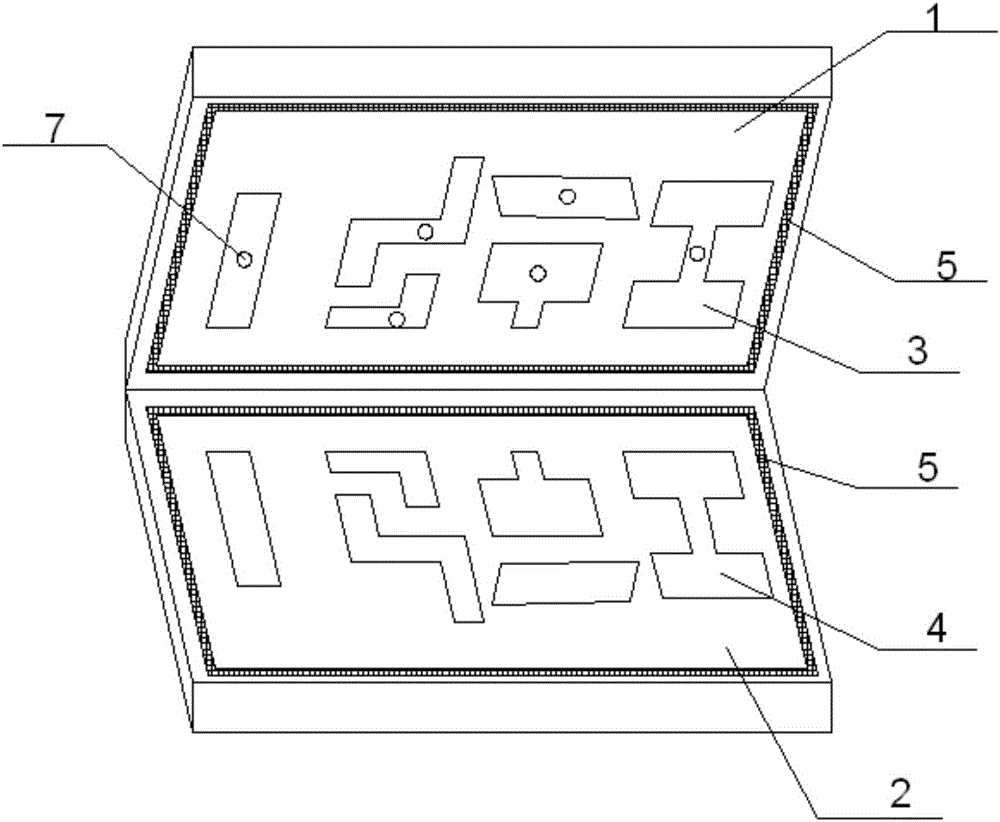

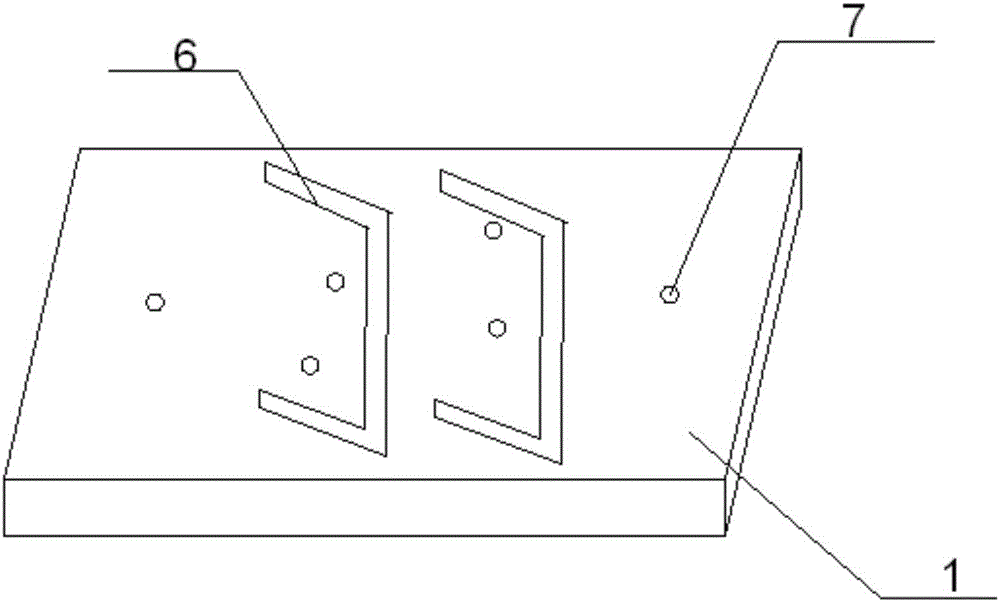

Novel chocolate mould

A chocolate and mold technology, applied in the field of new chocolate molds, can solve the problems of inconvenient chocolate taking out, easily damaged chocolate appearance, inconvenient to carry, etc., and achieves the effects of increasing interaction, improving aesthetics, and weakening water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

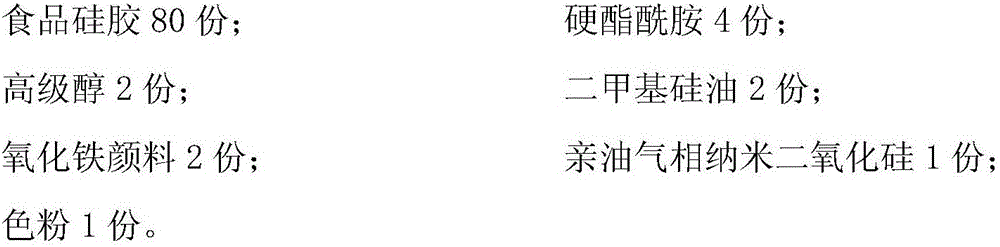

[0040] 1. Weigh the following raw materials in parts by weight:

[0041]

[0042] Among them, the iron oxide pigment is iron red, and the toner is red.

[0043] 2. The preparation method of the upper mold and the lower mold of the mold body of the present invention is the same, wherein, the upper mold is made through the following steps:

[0044] (1) Make the original mold: select the same amount of solid raw material according to the quantity set on the upper groove, and carve the solid material into the shape of the upper groove to obtain the prototype of the upper groove; Smear oil sludge on the surface of the upper groove, and after the oil sludge dries naturally, the prototype of the upper groove is polished, filled with soil, solidified, polished and air-tightness checked in sequence, and the original mold of the upper groove is obtained for subsequent use;

[0045] (2) Raw material processing: fully mix and stir the weighed raw materials until uniform, and then obta...

Embodiment 2

[0049] 1. Weigh the following raw materials in parts by weight:

[0050]

[0051] Among them, the iron oxide raw material is iron zinc yellow, and the toner is yellow.

[0052] 2. The preparation method of the upper mold and the lower mold of the mold body of the present invention is the same, wherein, the upper mold is made through the following steps:

[0053] (1) Make the original mold: select the same amount of solid raw material according to the quantity set on the upper groove, and carve the solid material into the shape of the upper groove to obtain the prototype of the upper groove; Smear oil sludge on the surface of the upper groove, and after the oil sludge dries naturally, the prototype of the upper groove is polished, filled with soil, solidified, polished and air-tightness checked in sequence, and the original mold of the upper groove is obtained for subsequent use;

[0054] (2) Raw material processing: fully mix and stir the weighed raw materials until unifor...

Embodiment 3

[0058] 1. Weigh the following raw materials in parts by weight:

[0059]

[0060] Wherein, the iron oxide raw material is iron orange, and the toner is orange.

[0061] 2. The preparation method of the upper mold and the lower mold of the mold body of the present invention is the same, wherein, the upper mold is made through the following steps:

[0062] (1) Make the original mold: select the same amount of solid raw material according to the quantity set on the upper groove, and carve the solid material into the shape of the upper groove to obtain the prototype of the upper groove; Smear oil sludge on the surface of the upper groove, and after the oil sludge dries naturally, the prototype of the upper groove is polished, filled with soil, solidified, polished and air-tightness checked in sequence, and the original mold of the upper groove is obtained for subsequent use;

[0063] (2) Raw material processing: fully mix and stir the weighed raw materials until uniform, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com