Manufacturing process for safety shoe toecap and manufactured safety shoe toecap

A production process and technology for safety shoes, applied in shoe uppers, footwear, applications, etc., can solve the problems of poor static pressure resistance and impact resistance of plastic toe caps, large self-weight of steel toe caps, poor insulation, etc., and achieve accurate internal and external dimensions. control, high impact resistance, good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

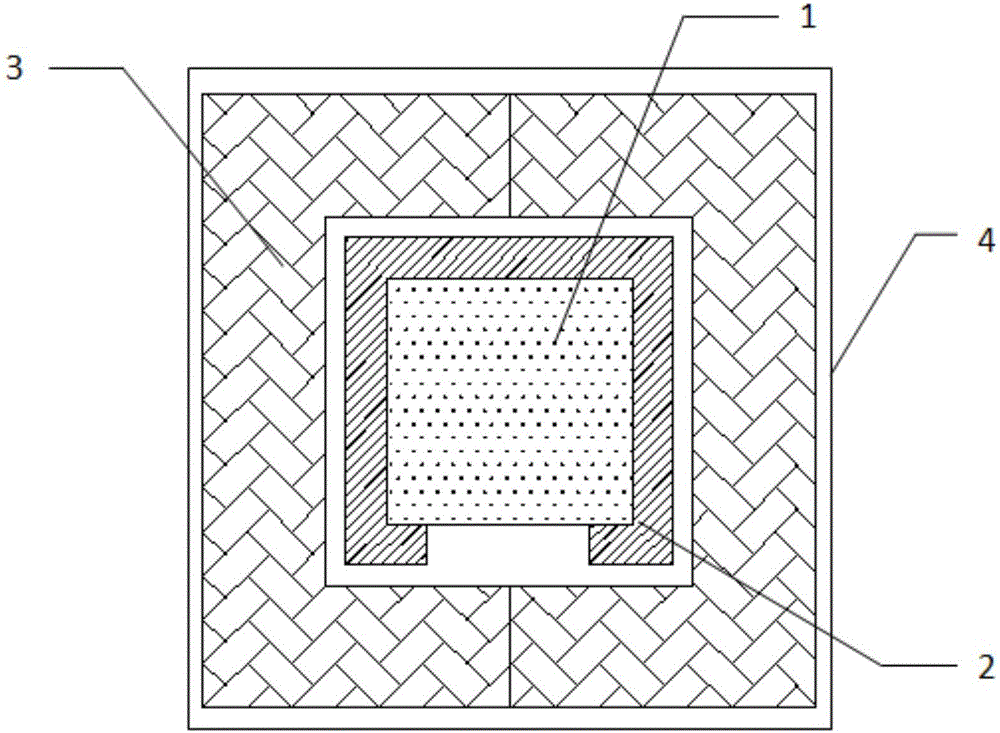

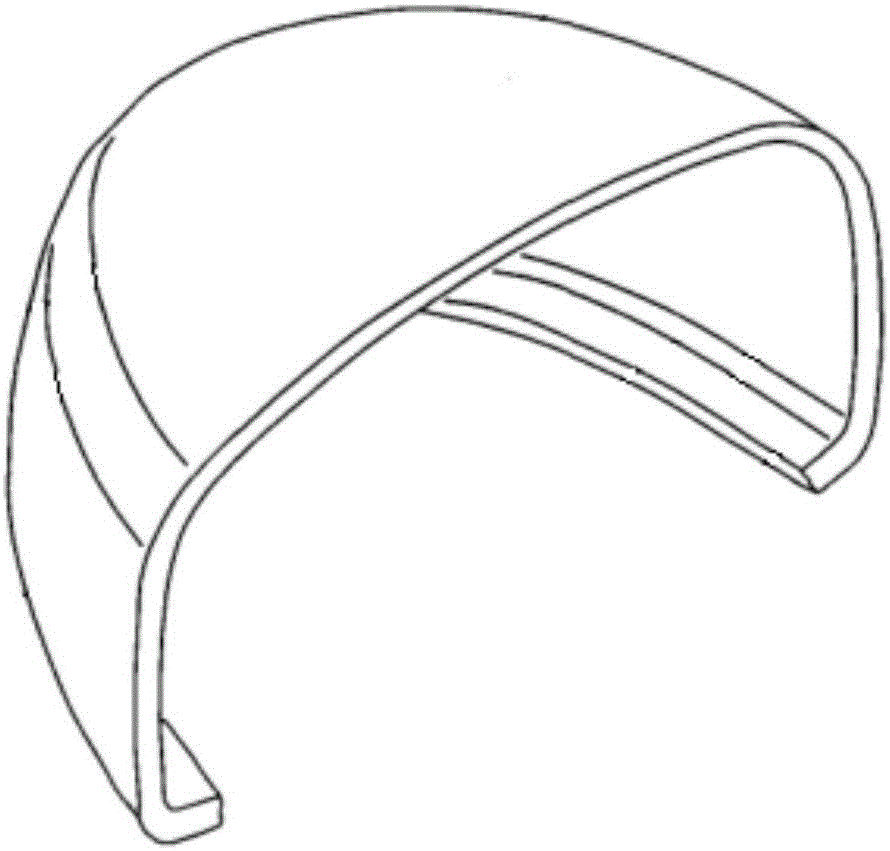

[0025] Such as figure 1 and figure 2 As shown, the present embodiment provides the manufacturing process of safety shoe toe caps, and the carbon fiber prepreg of required size is cut out by an automatic cutting machine (manufacturer: Jiangsu Hengshen, brand: EM101-T-200GSM, resin in carbon fiber prepreg 40% by weight) and glass fiber prepreg (manufacturer: Jiangsu Hengshen, brand: EW250B-900S, the weight percentage of resin in glass fiber prepreg is 40%), mandrel 1 and metal Match the outer mold 3 to form the shape of the toe cap for safety shoes, clean the surface of the core mold 1 and the metal outer mold 3 (ie the outer mold of the toe cap) with acetone, and then evenly coat the inner surface of the metal outer mold 3 with a release agent , the cut carbon fiber prepreg and glass fiber prepreg are placed on the surface of the core mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com