Rotational molding polyethylene composition and preparation method thereof

A technology of rotomolding and polyethylene, applied in the production of bulk chemicals, etc., can solve the problems of poor rigidity, strength and impact resistance, and achieve the effects of ensuring strength, good plasticization, loading capacity and catalytic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

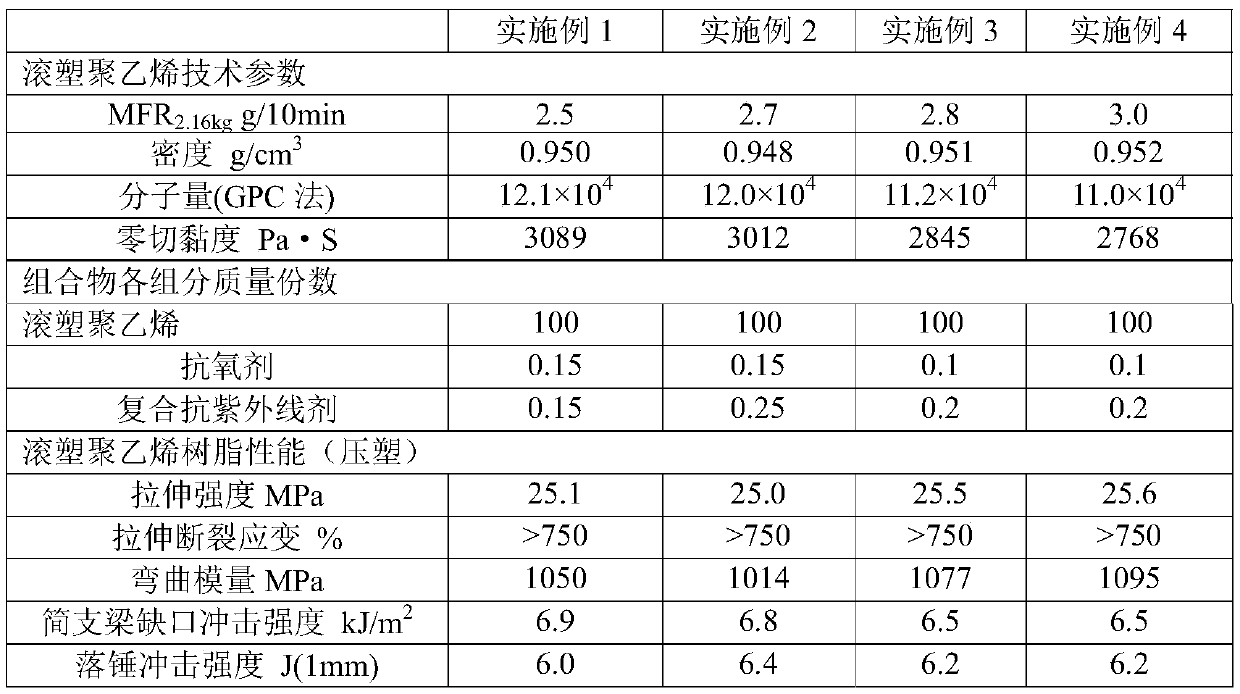

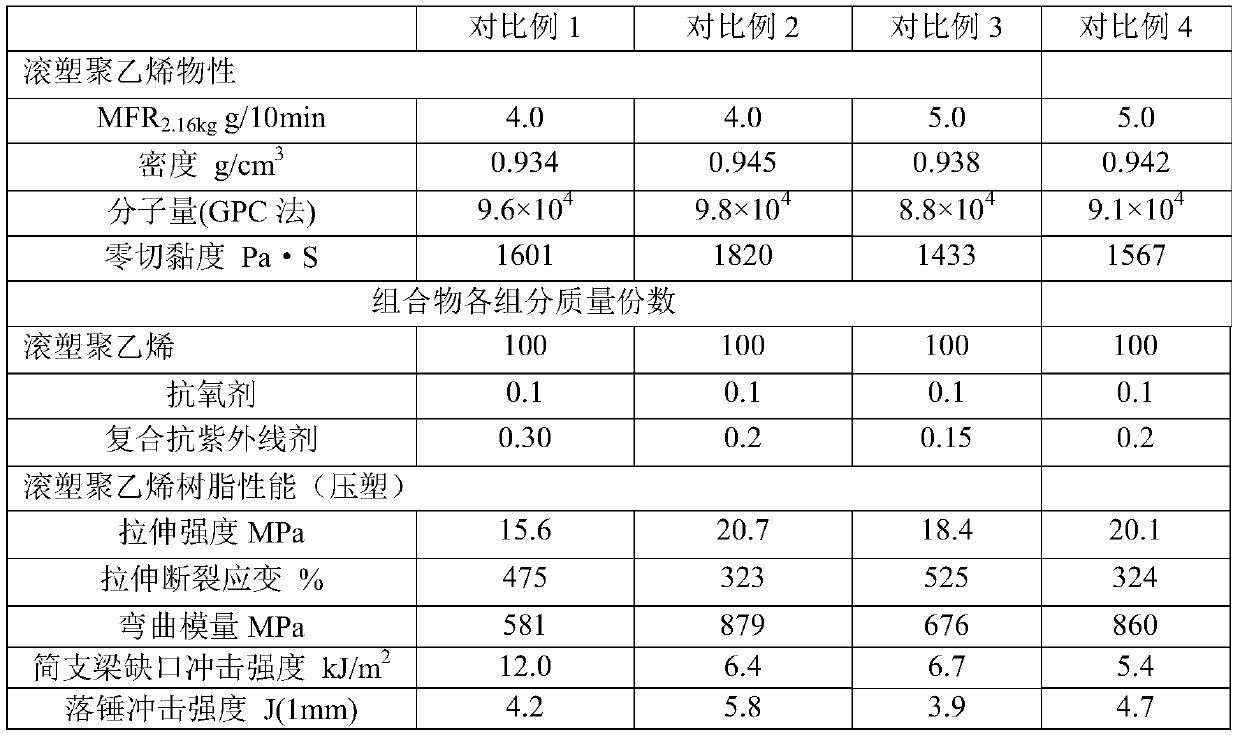

Examples

Embodiment 1

[0035] A. Activate 100kg of carrier silica gel, the activation temperature is 750℃, the activation time is 7h, and the specific surface area of the carrier silica gel is 280m 2 / g;

[0036] B. Add 1000 mol of dichloro-ethyl aluminum diluted with 5000 mol of n-hexane to the silica gel obtained in step A for treatment at a treatment temperature of 82° C., treatment for 4 hours, and dry into powder;

[0037] C. Add pre-mixed 5000mol tetrahydrofuran, 400mol magnesium chloride and 100mol titanium tetrachloride to the powder prepared in step B, the treatment temperature is 80°C, stirring for 30min, and drying;

[0038] D. Add 5000mol of n-hexane, 400mol of dichloro-ethyl aluminum, and 100mol of tri-n-hexyl aluminum to step C, stir for 30 minutes, and dry to obtain TiCl 4 / XROH / MgCl 2 / Et 3 Al titanium-containing catalyst, labeled as titanium-containing catalyst a.

[0039] The above steps are all carried out in a nitrogen atmosphere.

[0040] E. Using the titanium-containing catalyst prepar...

Embodiment 2

[0042] A. Activate 100kg of carrier silica gel, the activation temperature is 600℃, the activation time is 10h, and the specific surface area of the carrier silica gel is 280m 2 / g;

[0043] B. Add 1000 mol of dichloro-ethyl aluminum diluted with 5000 mol of n-hexane to the silica gel obtained in step A for treatment at a treatment temperature of 82° C., treatment for 4 hours, and dry into powder;

[0044] C. Add premixed 5000mol of tetrahydrofuran, 500mol of magnesium chloride and 100mol of titanium tetrachloride to the powder prepared in step B, the treatment temperature is 80°C, stirring for 30min, and drying;

[0045] D. Add 5000mol of n-hexane, 1000mol of dichloro-ethyl aluminum, and 500mol of tri-n-hexyl aluminum to step C, stir for 30 minutes, and dry to obtain TiCl 4 / XROH / MgCl 2 / Et 3 Al titanium-containing catalyst, labeled as titanium-containing catalyst b.

[0046] The above steps are all carried out in a nitrogen atmosphere.

[0047] E. Using the titanium-containing catal...

Embodiment 3

[0049] A. Activate 100kg of carrier silica gel, the activation temperature is 750℃, the activation time is 7h, and the specific surface area of the carrier silica gel is 280m 2 / g;

[0050] B. Add 1000 mol of dichloro-ethyl aluminum diluted with 5000 mol of n-hexane to the silica gel obtained in step A for treatment at a treatment temperature of 82° C., treatment for 4 hours, and dry into powder;

[0051] C. Add pre-mixed 5000mol tetrahydrofuran, 400mol magnesium chloride and 100mol titanium tetrachloride to the powder prepared in step B, the treatment temperature is 80°C, stirring for 30min, and drying;

[0052] D. Add 5000mol of n-hexane, 1000mol of dichloro-ethyl aluminum, and 500mol of tri-n-hexyl aluminum to step C, stir for 30 minutes, and dry to obtain TiCl 4 / XROH / MgCl 2 / Et 3 Al titanium-containing catalyst, labeled as titanium-containing catalyst c.

[0053] The above steps are all carried out in a nitrogen atmosphere.

[0054] E. Using the titanium-containing catalyst c pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com