Mechanical and electrical integrated glassware former

A technology of glassware and forming machines, applied in blown glass forming machines, glass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

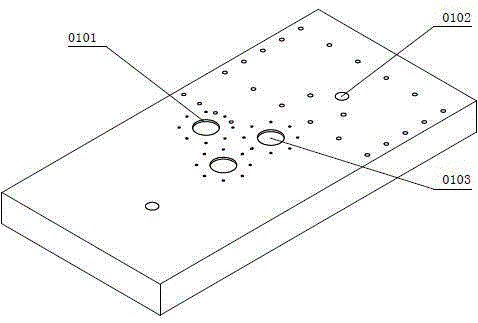

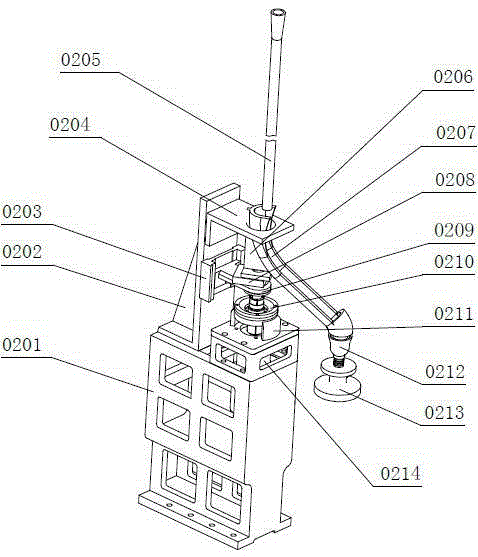

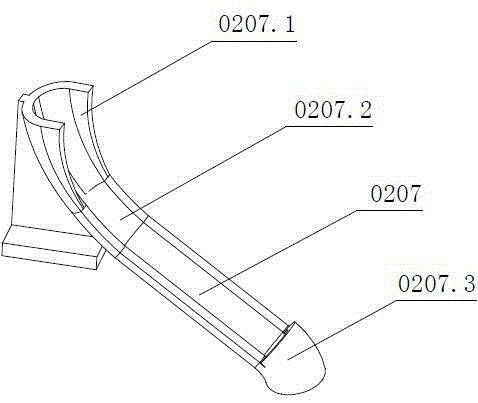

[0065] As shown in the figure: 1. An electromechanical integrated glassware forming machine. The common chassis is provided with 0-station positioning hole 0101, turntable center positioning hole 0102, 1-station positioning hole 0103, and 0-station positioning hole 0101 as the center point. Connect the 0-station bracket for reference positioning, set a feeding tube 0207 on the bracket, the feeding tube 0207 can swing around the axis of its feeding end, the feeding end of the feeding tube 0207 is matched with the discharging end of the feeding tube 0205, and the feeding tube 0207 is discharged The swing path at the end covers the 0212 feed port of the 1-station prototype mold. Feeding tube 0207 is a smooth arc tube. The feed pipe 0207 includes a feed end, a guide groove 0207.2, and a discharge end. The feed end and the guide groove 0207.2 are open above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com