Composite coating with metal corrosion resistance and preparation method thereof

A composite coating and metal corrosion technology, which is applied in the field of metal anti-corrosion, can solve the problems of unstable and uneven coating, achieve the effect of improving anti-corrosion effect, no side effects, and improving the stability of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

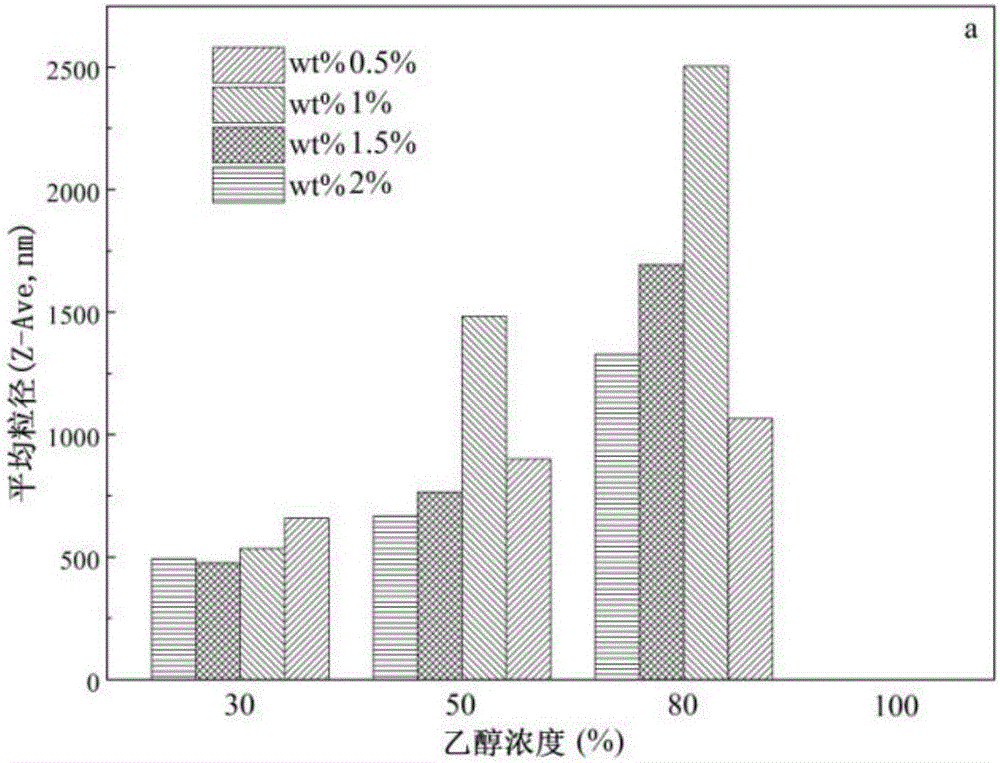

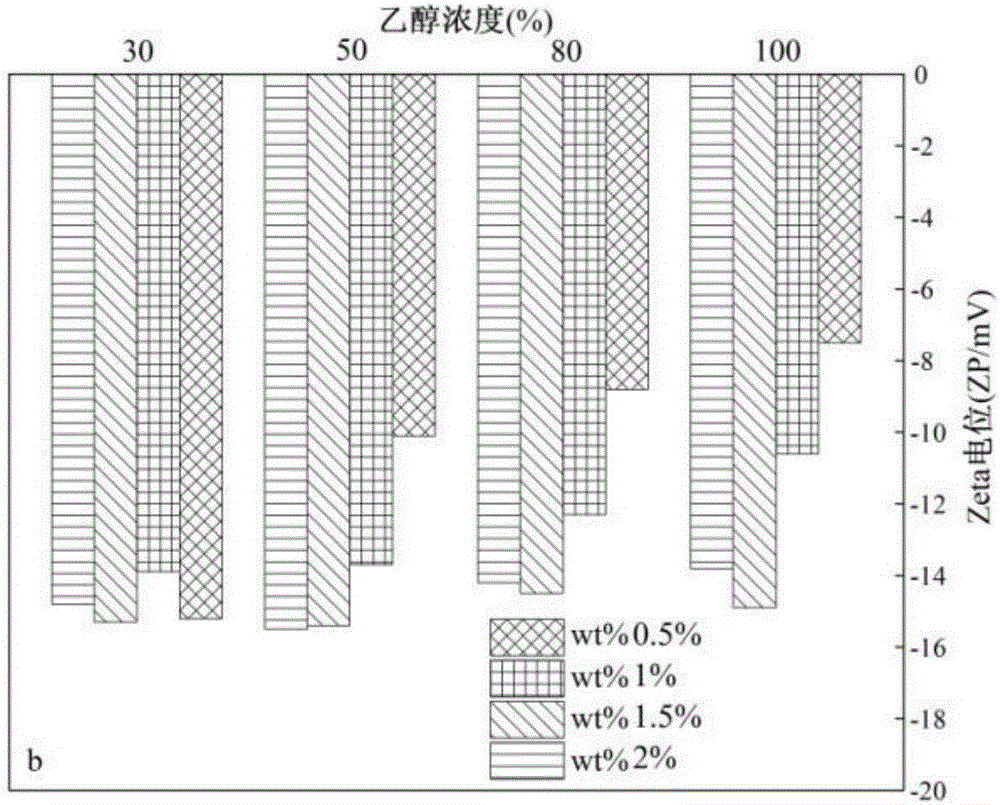

[0046] At room temperature around 25°C, add 0.4685-1.874g of hydrophilic SiO to 100mL ethanol solutions with volume concentrations of 30%, 50%, 80%, and 100%, respectively. 2 Nanoparticle powder, and use an ultrasonic pulverizer to process 5-10min at 20±5°C to prepare 0.5wt%, 1wt%, 1.5wt%, 2wt% SiO 2 Nano solution, each solution is adjusted to pH 8-9 with 1mol / L NaOH solution.

[0047] Prepared SiO 2 Nanoparticle solution testing zeta potential, SiO in solution 2 The average particle size of colloidal particles, the results are shown in Figure 2. The larger the absolute value of the Zeta potential, the more charges on the particle surface, indicating that the nano-SiO 2 The greater the charge, the stronger the electrostatic adsorption. According to Figure 2, comparing the Zeta potential values at the same mass percentage concentration and different ethanol concentrations, it can be found that the potential is the most negative when the ethanol concentration is 30%, and i...

Embodiment 2

[0050] 1) The mass percentage concentration that is configured in the ethanol solution of volume concentration 30% is 1.5% SiO 2 Nanoparticle solution, method is the same as embodiment 1;

[0051] 2) PAH polyallylamine hydrochloride solution: at a room temperature of about 25°C, add 200mg of polyallylamine hydrochloride to 100mL of purified water, stir at room temperature to fully mix and dissolve;

[0052] 3) EPS extracellular polymer solution: add 20-40mg of Pseudomonas extracellular polymer powder in 100mL of purified water at room temperature around 25°C, stir at room temperature to fully mix and dissolve;

[0053] Table 1 shows the zeta potential and solute average particle size test results of EPS solution concentrations of 200 and 400 mg / L. Under different concentration conditions, the corrosion mass loss on the second day and the fifth day is as follows: image 3 shown.

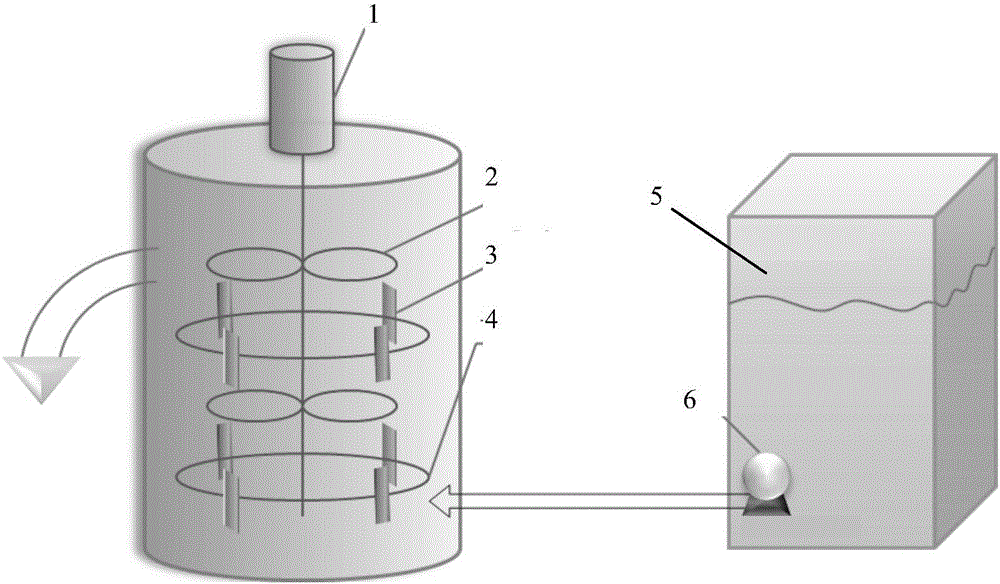

[0054] 4) The paint coating method adopts the LbL layer-by-layer self-assembly method, and the ...

Embodiment 3

[0072] 1) The mass percentage concentration that is configured in the ethanol solution of volume concentration 30% is 1.5% SiO 2 Nanoparticle solution, method is the same as embodiment 1;

[0073] 2) PAH polyallylamine hydrochloride solution: at a room temperature of about 25°C, add 200mg of polyallylamine hydrochloride to 100mL of purified water, stir at room temperature to fully mix and dissolve;

[0074] 3) EPS extracellular polymer solution: the EPS solution concentration is 400 mg / L, and the preparation method is the same as in Example 2.

[0075] 4) The paint coating method adopts the LbL layer-by-layer self-assembly method, and the positive and negative electrolyte solutions are alternately dipped. Dip-coat each layer for 15, 35, and 45 minutes at 4°C, and the dip-coating sequence is as follows: SiO 2 Nano solution / PAH solution / EPS solution / PAH solution / EPS solution / PAH solution / SiO 2 Nano solution, freeze-dried at -50±5°C for 12h (the pre-cooling temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com