A self-healing coating with photothermal effect and its preparation and application method

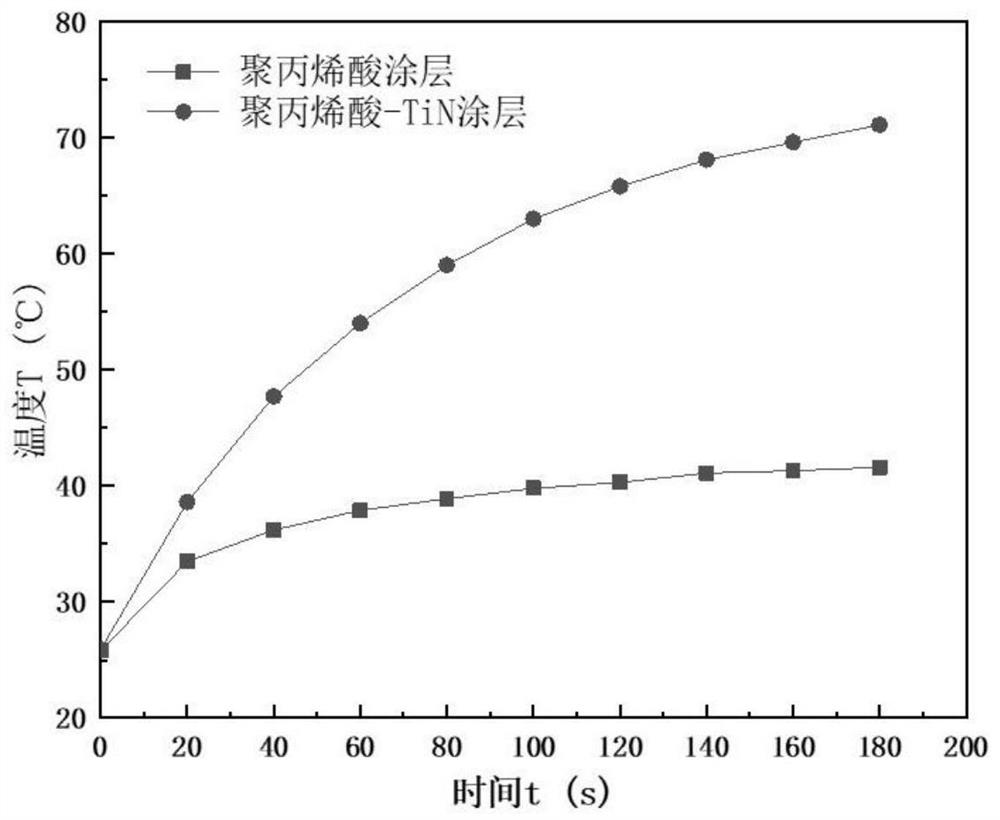

A technology of photothermal effect and application method, which is applied in the direction of coating, anti-corrosion coating, epoxy resin coating, etc., can solve the problems of increasing coating preparation cost, etc., and achieve low production cost, recovery protection ability, corrosion resistance and self-healing good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Polish the stainless steel sheet with sandpaper, then ultrasonically clean it with acetone, alcohol, and deionized water in sequence and dry it;

[0018] 2. Disperse titanium nitride nanoparticles with a particle size of 20nm in tetrahydrofuran: take 0.006g of nano-titanium nitride and add it to 2g of tetrahydrofuran, and stir magnetically for 30min at a speed of 600rpm;

[0019] 3. Dissolve 2g of polyacrylic acid in 6g of tetrahydrofuran, and dissolve it at 80°C and 400rpm to form a homogeneous solution;

[0020] 4. Mix titanium nitride with polyacrylic acid solution, and disperse evenly at 90°C and 800rpm for 20 minutes to ensure that the mass fraction of titanium nitride solvent after volatilization is 0.3%;

[0021] 5. Apply the titanium nitride-polyacrylic acid composite solution evenly on the surface of the stainless steel sheet by the bar coating method;

[0022] 6. Dry in an oven at 80°C for 12 hours, and the thickness of the coating after curing is 50 μm. ...

Embodiment 2

[0027] 1. Polish the aluminum alloy sheet with sandpaper, then ultrasonically clean it with acetone, alcohol, and deionized water in sequence, and dry it;

[0028] 2. Disperse titanium nitride nanoparticles with a particle size of 30nm in tetrahydrofuran: take 0.06g of nano-titanium nitride and add it to 2g of tetrahydrofuran, and stir magnetically for 30min at a speed of 600rpm;

[0029] 3.3g of polystyrene powder was dissolved in 50mL of tetrahydrofuran for use;

[0030] 4. Mix the titanium nitride and polystyrene solution, and stir at 70rpm to reach a certain viscosity, and ensure that the mass fraction of the titanium nitride solvent after volatilization is 2.0%;

[0031] 5. Spray the titanium nitride-polystyrene composite solution on the surface of the aluminum alloy sheet, and use a spray gun to spray the composite solution evenly on the aluminum alloy sheet at 0.6 MPa, and the nozzle is 10 to 15 cm from the surface of the sample;

[0032] 6. Dry in an oven at 60°C for ...

Embodiment 3

[0036] 1. Grind the carbon steel sheet with sandpaper, then ultrasonically clean it with acetone, alcohol, and deionized water in sequence, and dry it;

[0037] 2. Disperse titanium nitride nanoparticles with a particle size of 80nm in N,N-dimethylformamide: take 0.08g of nano-titanium nitride and add it to 1gN,N-dimethylformamide, at a speed of 600rpm Next, magnetically stir for 30min;

[0038] 3. Dissolve 2g of polyurethane in 7g of N,N-dimethylformamide, and dissolve it into a homogeneous solution at 90°C and 800rpm;

[0039] 4. Mix titanium nitride and polyurethane solution, and disperse evenly at 90°C and 800rpm for 20 minutes to ensure that the mass fraction of titanium nitride solvent is 4.0% after volatilization;

[0040] 5. Spin-coat the titanium nitride-polyurethane composite solution on the surface of the carbon steel sheet at a speed of 300rpm for 20s;

[0041] 6. Curing in an oven at 55°C for 24 hours, the coating thickness after curing is 100μm.

[0042]7. Use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com