Electromagnetic vacuum annealing furnace

A vacuum annealing furnace, electromagnetic technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of poor magnetic field uniformity, slow heating and cooling rate, low temperature response sensitivity, etc. The effect of fast cooling rate and easy heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

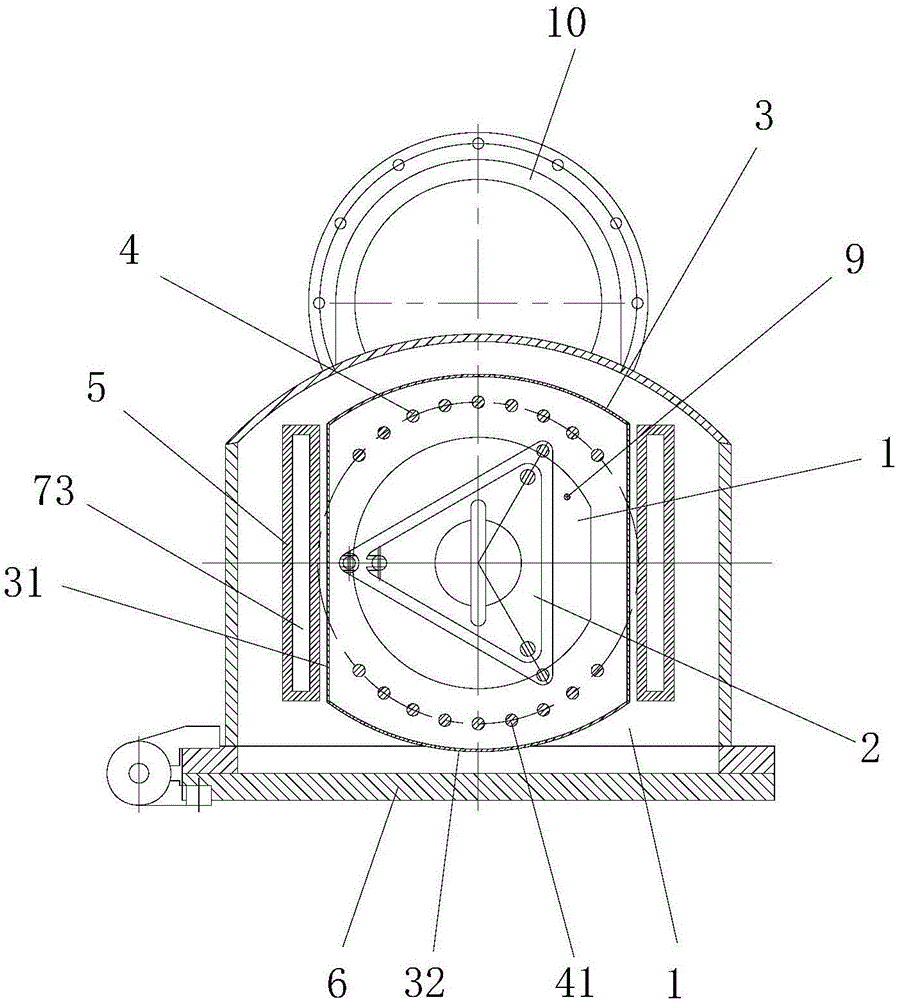

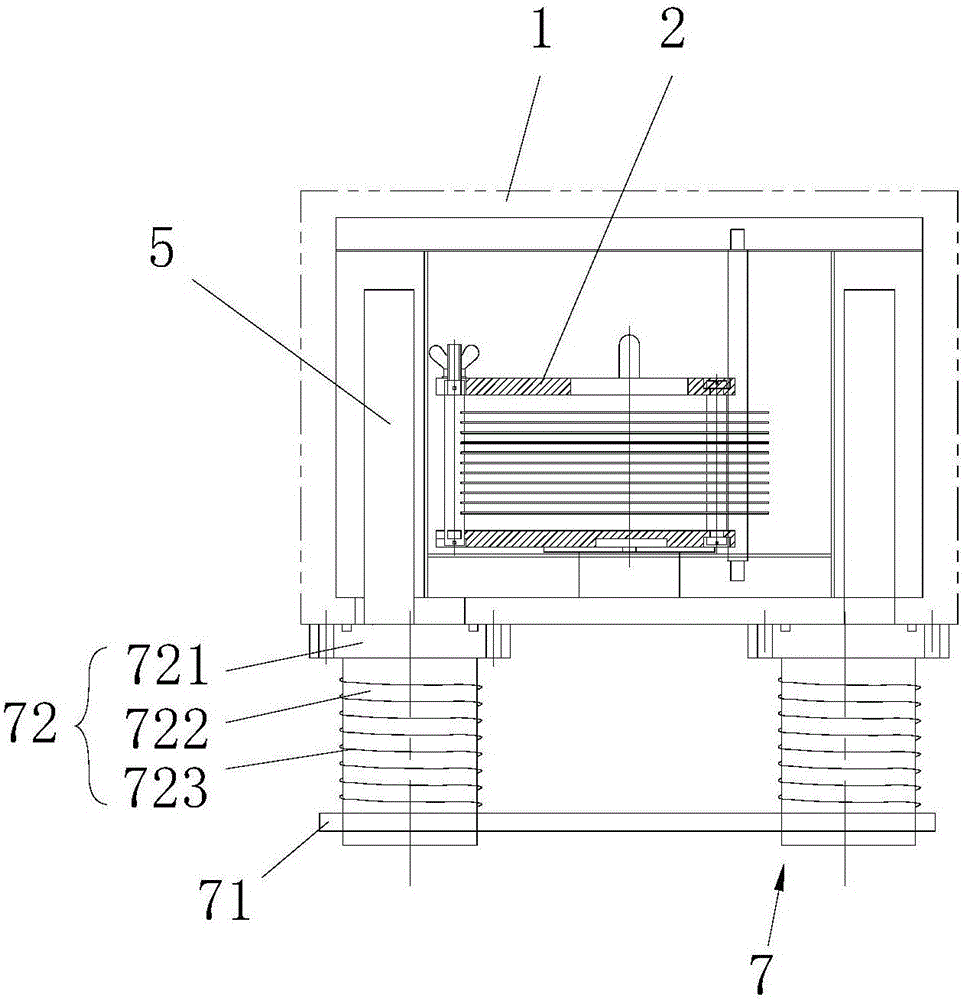

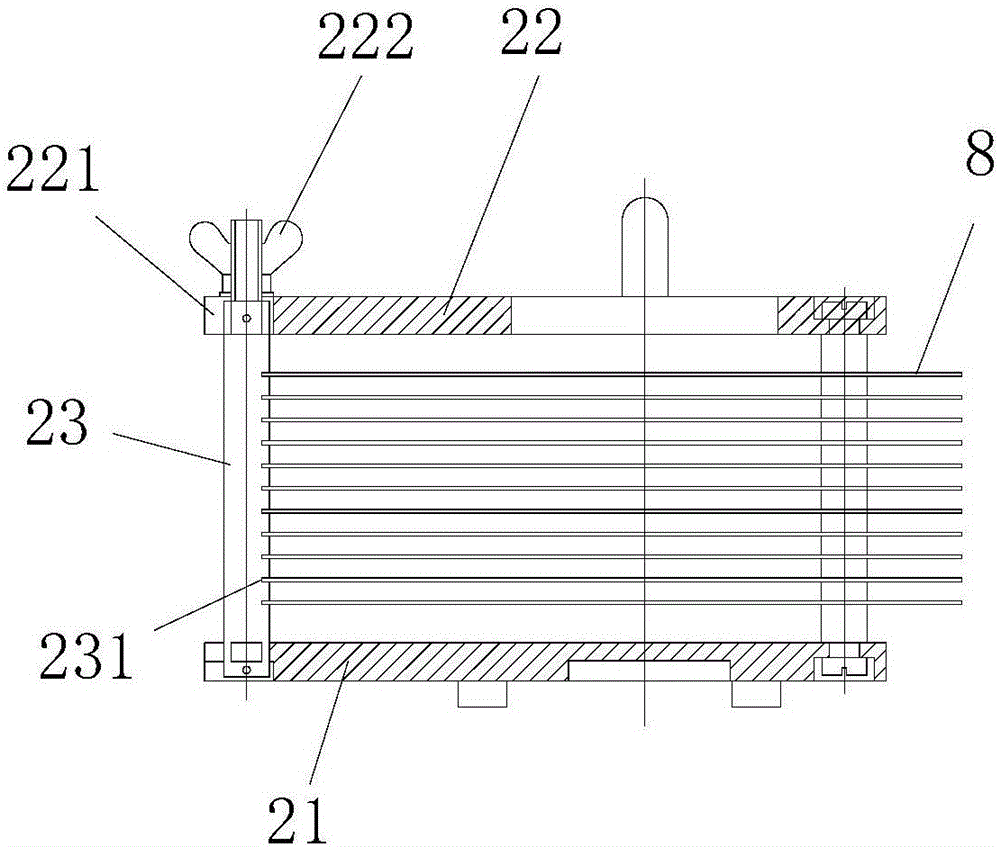

[0024] Such as Figure 1 to Figure 4 As shown, the electromagnetic vacuum annealing furnace of this embodiment includes a vacuum chamber 1 and a sample holder 2 located in the vacuum chamber 1, and also includes a heat shield 3 located in the vacuum chamber 1, and at least one set of infrared lamp assemblies 4 and two magnetic poles 5 for generating a magnetic field, the sample holder 2 and the infrared lamp assembly 4 are located inside the heat shield 3, and the two magnetic poles 5 are located outside the heat shield 3 and symmetrically arranged on both sides of the sample holder 2. The vacuum annealing furnace uses infrared lamp assembly 4 for radiation heating, which is easy to control the heating process, has a fast heating and cooling rate, avoids pollution and complicated winding work, and does not affect the magnetic field di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com