Noctilucous coated cloth and preparation method thereof

A luminous coating and coating technology, applied in the field of coated cloth, can solve the problems of reducing the aesthetic effect of imaging, not meeting high output and low cost, wasting time and heating energy, etc., and achieving exquisite patterns, stable lighting, and difficulty in The effect of environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

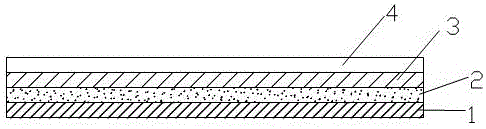

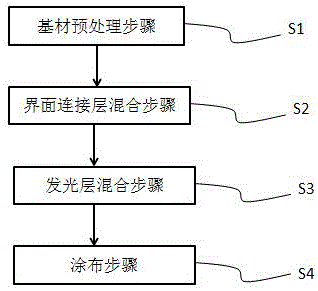

[0032] Refer to attached Figure 1~2 , the luminous coated cloth of the present embodiment, which comprises a substrate 1, an interface connection coating 2, a luminous coating 3 and a protective layer 4, the interface connection coating 2 is coated on the upper surface of the substrate 1 by coating, and the luminous The coating 3 is coated on the upper surface of the interface coating 2 by coating, and the protective layer 4 is coated on the upper surface of the luminous coating 3 .

[0033] In fact, the material of the base material can be cotton cloth, linen cloth, polyester cloth, non-woven fabric or polyester-cotton-linen mixed cloth, etc., which require luminous coating. The base material 1 used in this embodiment is made of polyester-cotton linen.

[0034] To prepare interface coating materials, weigh 30 kg of deionized water, 0.3 kg of dispersant, 0.3 kg of defoamer, 25 kg of titanium dioxide, 20 kg of PVA emulsion, 20 kg of acrylic emulsion, and 5 kg of thickener, and...

Embodiment 2

[0047] The luminous coated cloth of this embodiment includes a substrate 1, an interface connection coating 2, a luminous coating 3 and a protective layer 4. The interface connection coating 2 is coated on the upper surface of the substrate 1 by coating, and the luminous coating The layer 3 is coated on the upper surface of the interface connection coating 2 by coating, and the protective layer 4 is coated on the upper surface of the luminous coating 3 .

[0048] In fact, the material of the base material can be cotton cloth, linen cloth, polyester cloth, non-woven fabric or polyester-cotton-linen mixed cloth, etc., which require luminous coating. The base material 1 used in this embodiment is made of polyester-cotton linen.

[0049] To prepare interface coating materials, weigh 40 kg of deionized water, 0.4 kg of dispersant, 0.4 kg of defoamer, 30 kg of titanium dioxide, 25 kg of PVA emulsion, 25 kg of acrylic emulsion, and 6 kg of thickener, and put them into Mix in a stainl...

Embodiment 3

[0058] The luminous coated cloth of this embodiment includes a substrate 1, an interface connection coating 2, a luminous coating 3 and a protective layer 4. The interface connection coating 2 is coated on the upper surface of the substrate 1 by coating, and the luminous coating The layer 3 is coated on the upper surface of the interface connection coating 2 by coating, and the protective layer 4 is coated on the upper surface of the luminous coating 3 .

[0059] In fact, the material of the base material can be cotton cloth, linen cloth, gray cloth, polyester fiber, non-woven fabric, polyester cotton linen, etc., which require luminous coating. The base material 1 used in this embodiment is made of polyester cotton linen.

[0060] To prepare interface coating materials, weigh 20 kg of deionized water, 0.2 kg of dispersant, 0.2 kg of defoamer, 20 kg of titanium dioxide, 15 kg of PVA emulsion, 15 kg of acrylic emulsion, and 4 kg of thickener, and put them into Mix in a stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com