A whole bundle of jacking steel wires and hole cleaning method for demolishing old suspenders of arch bridges

A boom and jacking technology, which is applied in bridges, bridge construction, bridge maintenance, etc., can solve the problems of high construction cost, long construction time, large size, and easy jamming of pneumatic picks or pneumatic drills in the gap between steel wires and cable guides. It achieves the effect of low manual work intensity, short construction time and convenient standardized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

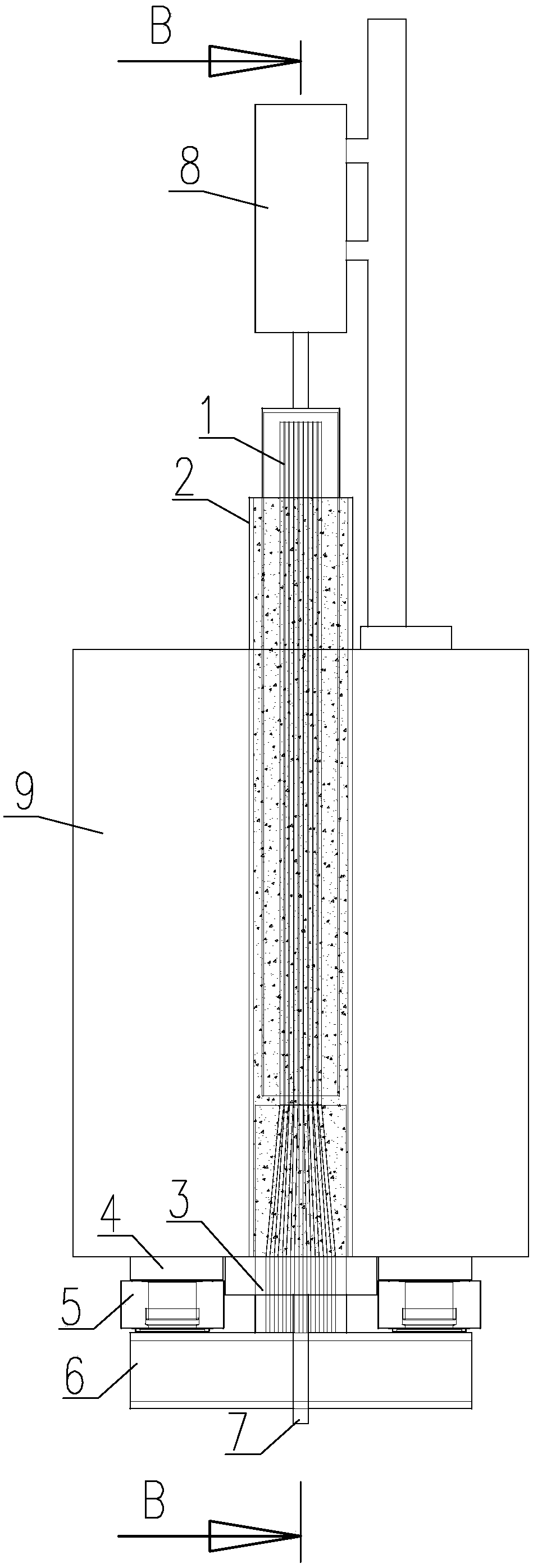

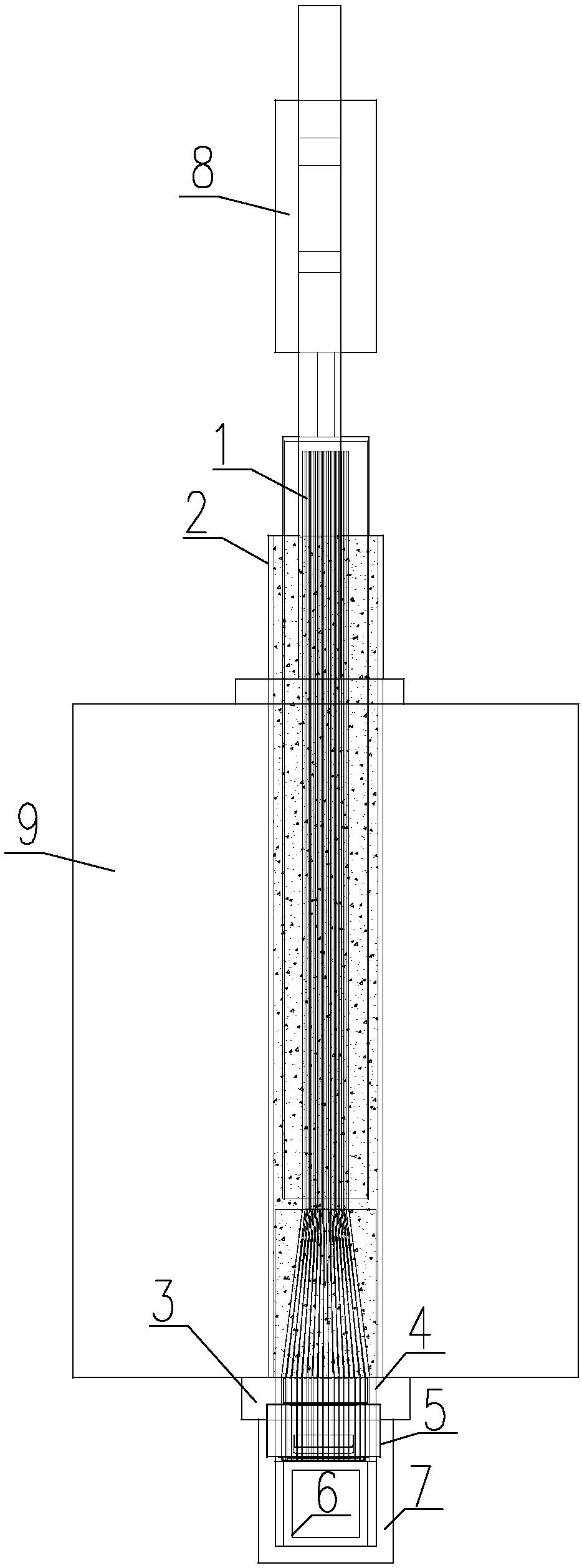

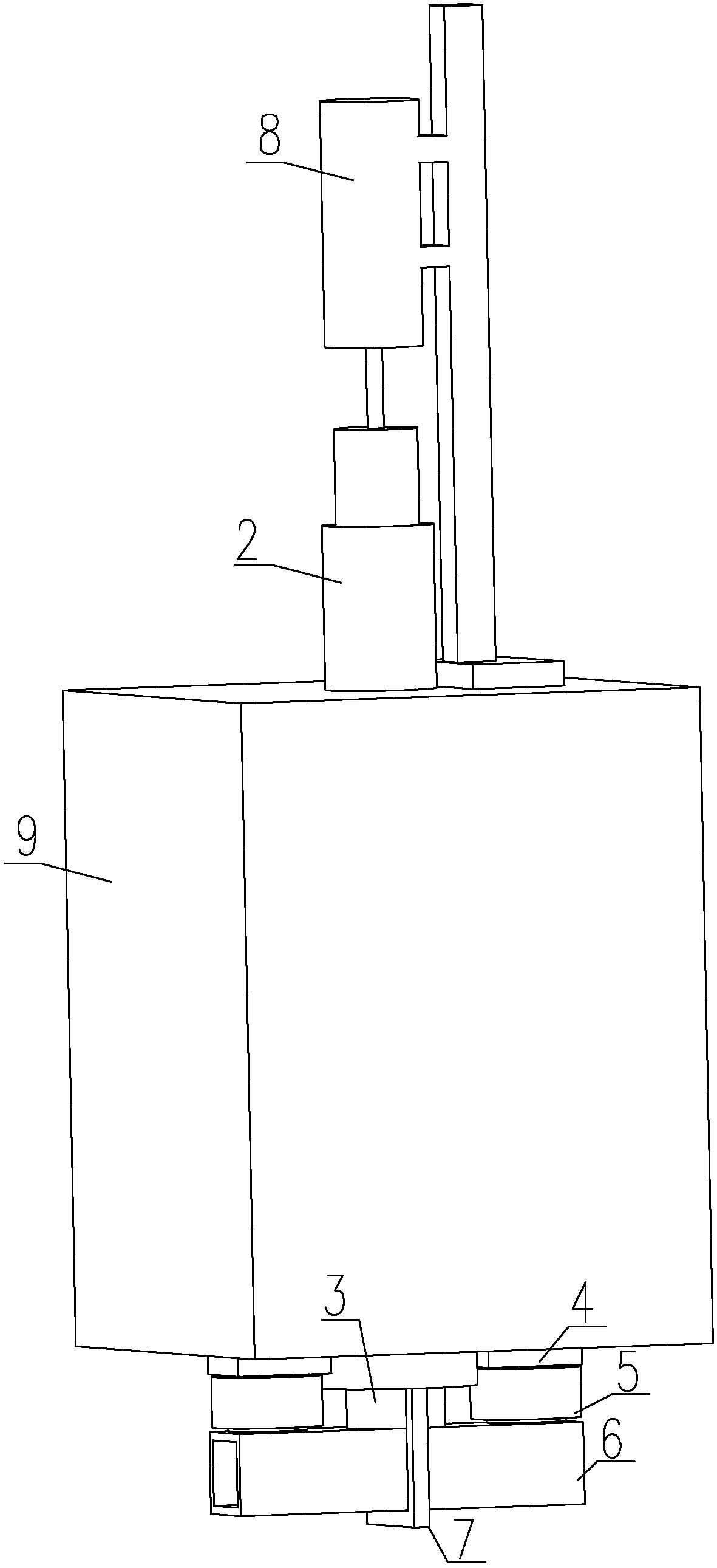

[0027] A complete bundle of jack-up device components for boom replacement and hole cleaning:

[0028] like Figure 1 to Figure 3 As shown, the whole bundle of jacking device components includes U-shaped hoop 7, flat pole steel beam 6, flat jack 5 and steel cushion block 4 installed in sequence;

[0029] In the use state: the U-shaped hoop 7 and the wire anchor head 3 to be pulled out are fixedly connected by welding, the flat pole steel beam 6 is installed between the wire anchor head 3 to be pulled out and the bottom of the U-shaped hoop 7, and the flat jack 5 is installed on the bridge Between the bottom surface of the lower beam 9 and the top surface of the end of the steel beam 6 of the flat pole, the steel block 4 as the height adjustment block of the flat jack is installed between the bottom surface of the boom beam 9 and the top of the flat jack 5, and drives the flat jack 5 to reverse the flat pole The steel beam 6 and the U-shaped hoop 7 realize the whole bunch of to...

Embodiment 2

[0032] A whole bundle of top-drawing steel wires used for dismantling old hangers of arch bridges and method for cleaning holes

[0033] The method is to use the whole bundle of jacking device components for replacing the hanger rod described in the first embodiment to remove the old hanger rod of the arch bridge and implement the whole bundle of jacking wire and hole cleaning method, that is, first use a concrete core drilling machine Drill holes from top to bottom on the bridge deck to the anchor head section of the old boom, and then use the whole bundle of jacking device components to use hydraulic flat jacks to lift the steel wire or steel strand anchor head of the old boom of the arch bridge. The specific method and steps of hole cleaning are:

[0034] A. Drilling: Use the concrete core drilling rig 8 to drill from top to bottom on the bridge deck to the old boom anchor section;

[0035] B. Install the whole bundle of jack-up device components used for the replacement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com