A modular building component and building component forming machine and construction method thereof

A technology of building components and modularization, applied in building components, building structures, buildings, etc., can solve the problems that can only be used in vegetable greenhouses, mobile houses, light wall panels cannot bear load, and the area of production line workshops is large, etc., to achieve The effect of improving the safety level of earthquake resistance and windproof, low labor intensity of workers, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

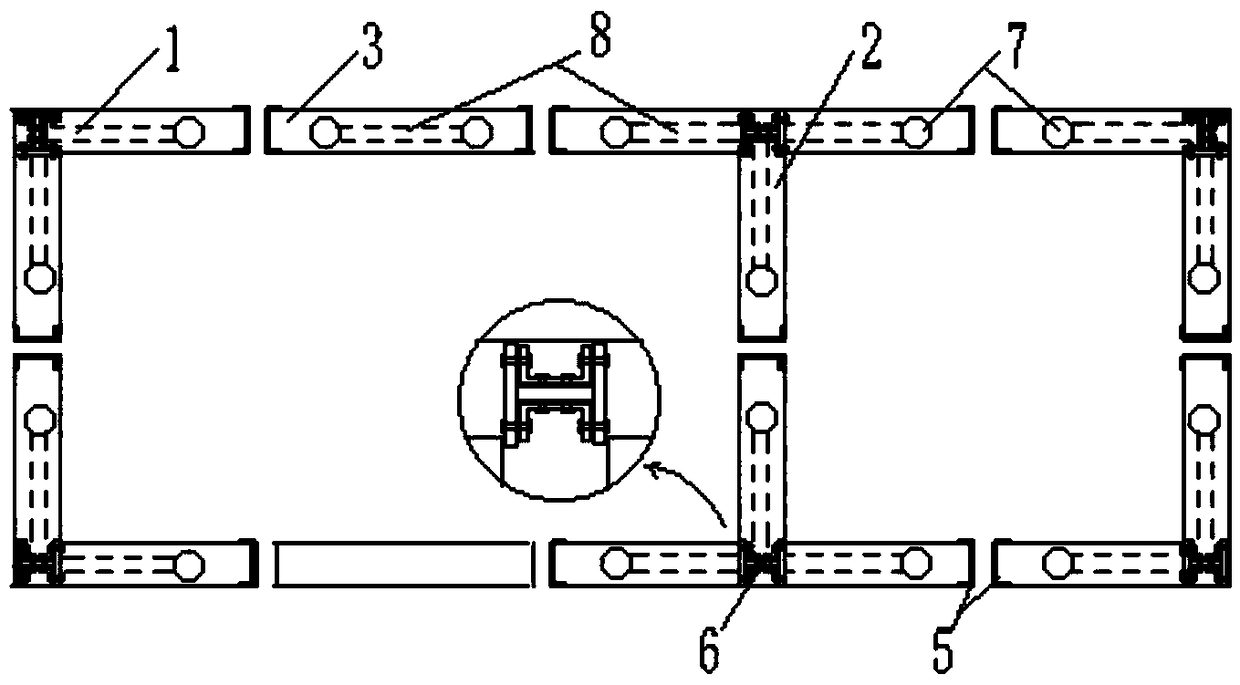

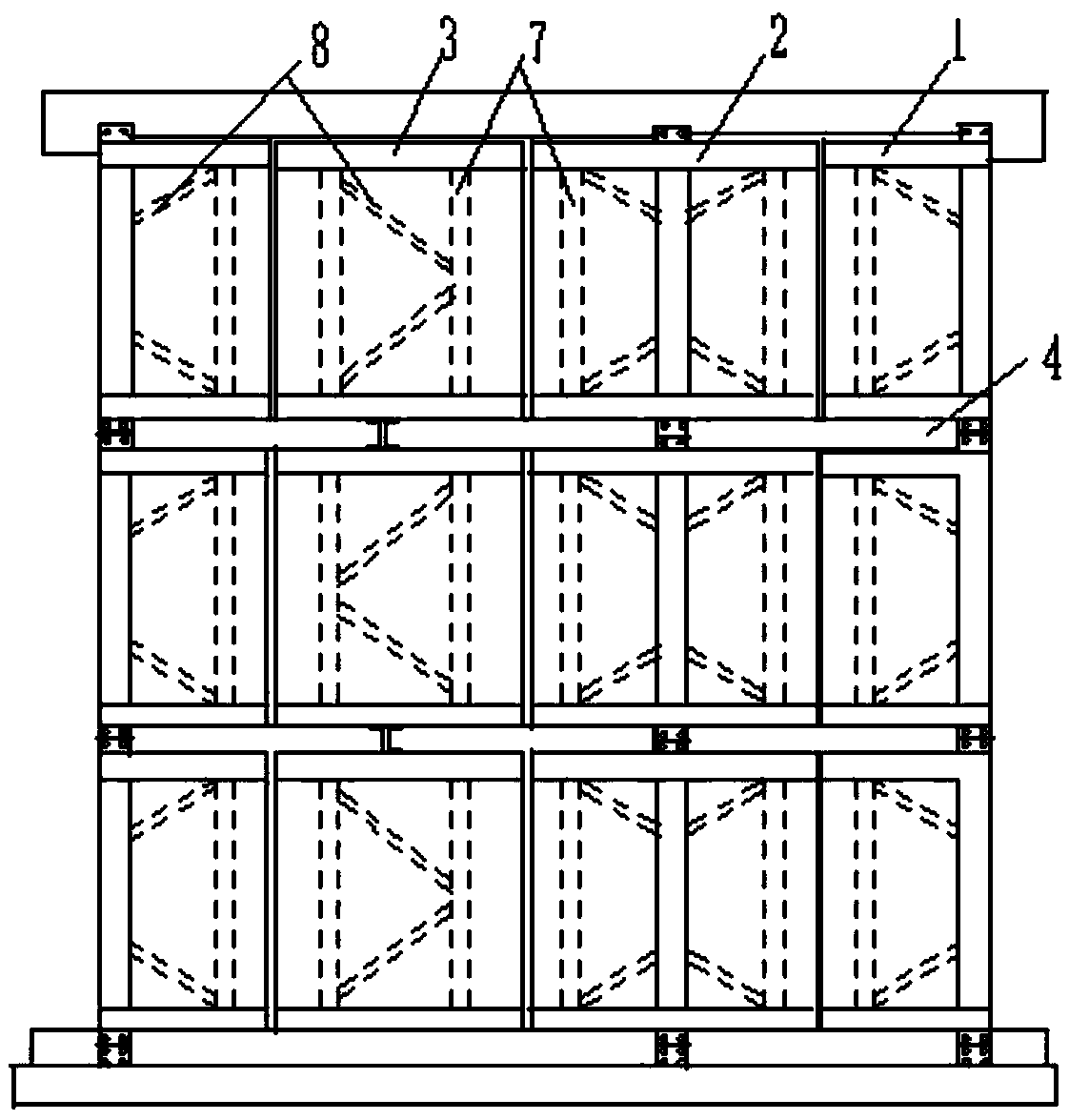

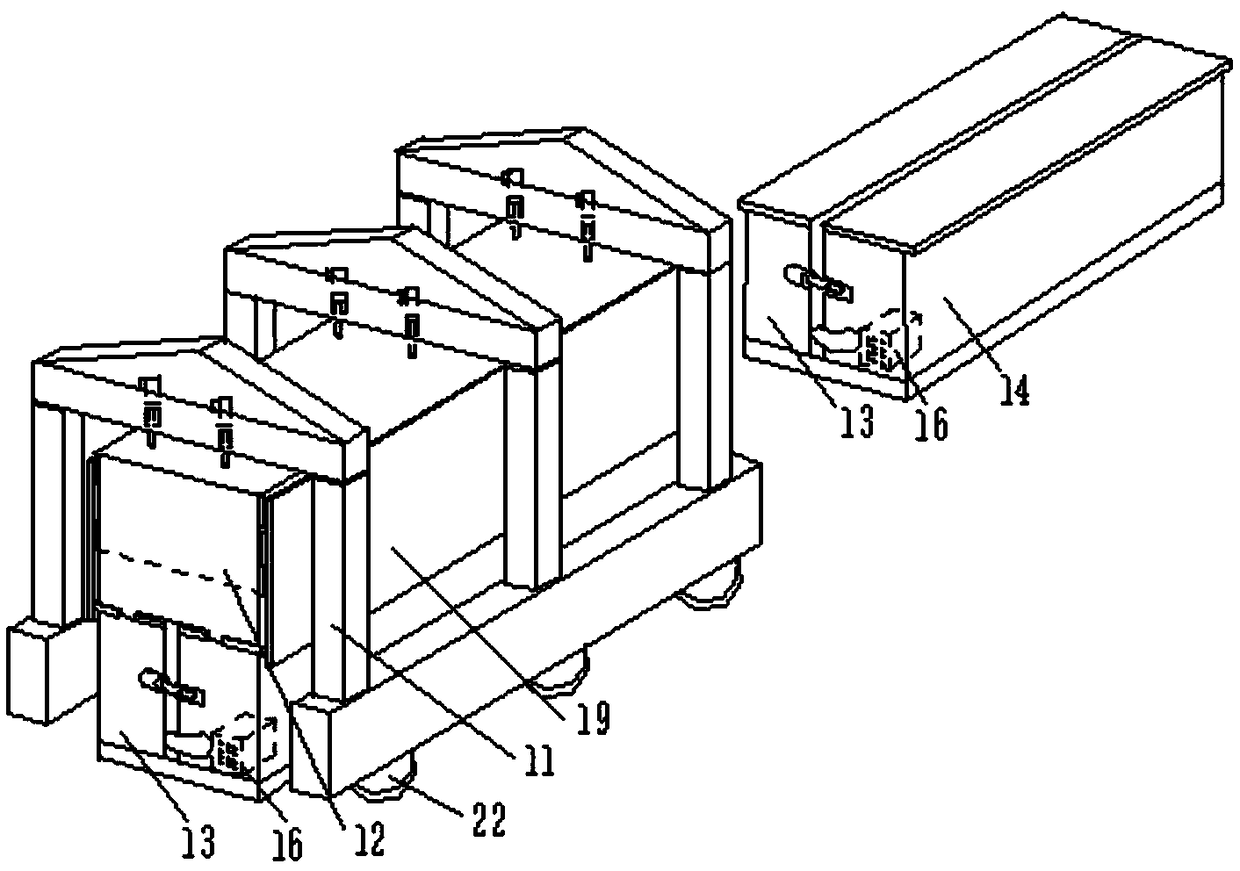

[0028] Such as figure 1 As shown, the building components of the present invention are standard parts that can be assembled with each other, including composite panels in four shapes: L-shaped shear wall panel 1, T-shaped shear wall panel 2, inline shear wall panel 3 and floor slab 4, The size of the composite plate is 200-7800mm in length, 100-1200mm in width and 120-180mm in thickness. The composite board includes pressure cement board 9, flame-retardant polyurethane, support structure and channel steel 5, and the facade of the board is two A-class fireproof pressure cement boards. The board as the floor is sealed around by channel steel 5, and the top and bottom ends of the board of the wall board are sealed by channel steel. The interior of the composite board is filled with flame-retardant polyurethane between the two pressure cement boards and the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com