Method for layered construction of main power house

A layered construction and main factory building technology, applied in industrial buildings, infrastructure engineering, construction, etc., can solve problems such as unfavorable traffic safety, long construction period, and poor construction conditions, so as to avoid potential safety hazards, speed up construction progress, avoid The effect of cross-job

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

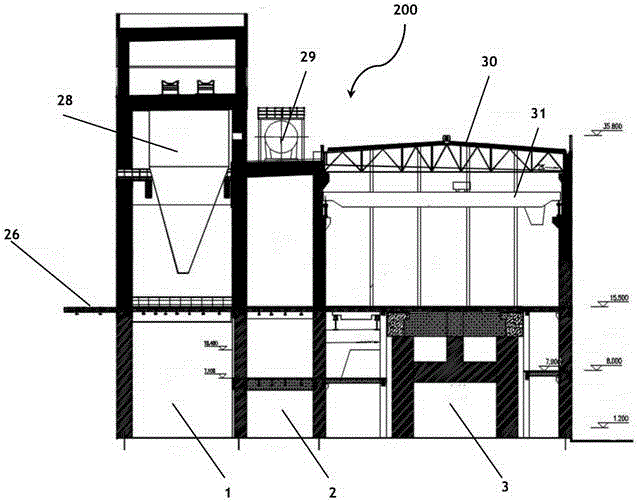

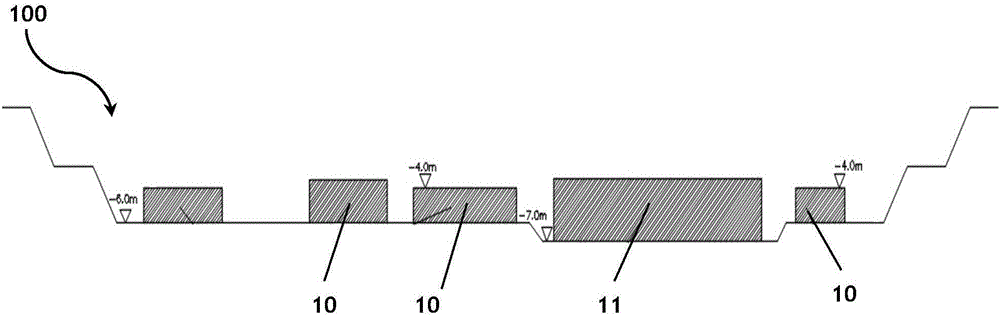

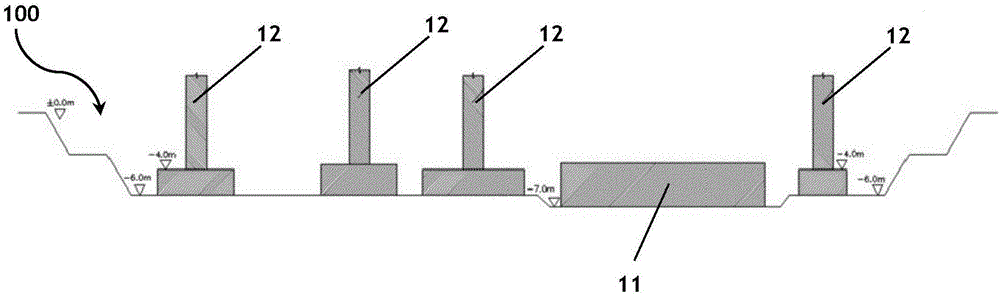

[0044] The main plant structure includes a foundation part 100 and a plant superstructure 200 . The foundation part 100 includes foundation cap 10 , foundation short column 12 , steam turbine foundation 11 , 13 , pipe trench 14 , deep foundation 15 and embedded pipe 16 . The plant superstructure 200 includes a coal bunker room 1 , a deoxygenation room 2 and a turbine room 3 .

[0045] Specifically, such as Figure 5 As shown, the coal bunker room 1 is formed between the D column 20 and the C column 21, the deaeration room 2 is formed between the C column 21 and the B column 22, and the turbine room 3 is formed between the B column 22 and the A column 23.

[0046] Such as figure 2 As shown, S1 constructs the foundation cap and steam turbine foundation of the foundation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com