Method for evaluating integrity of well cementing barrier

An integrity and cementing technology, applied in earthwork drilling, wellbore/well components, measurement, etc., can solve problems such as changes in the stress state of the cementing barrier system, economic losses, formation fluid in the annular space, etc., to achieve The experimental data is true and reliable, the experimental steps are clear, and the experimental principle is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

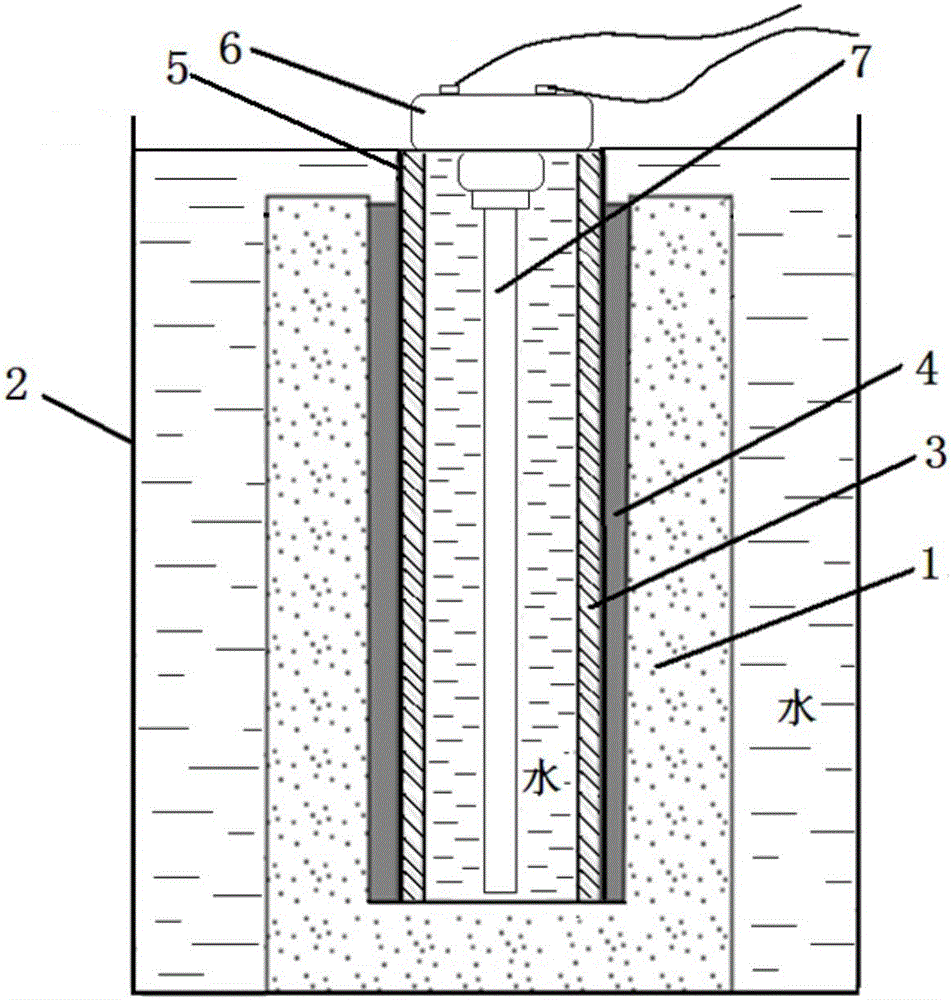

[0038] 1. The implementation process of free casing is as follows:

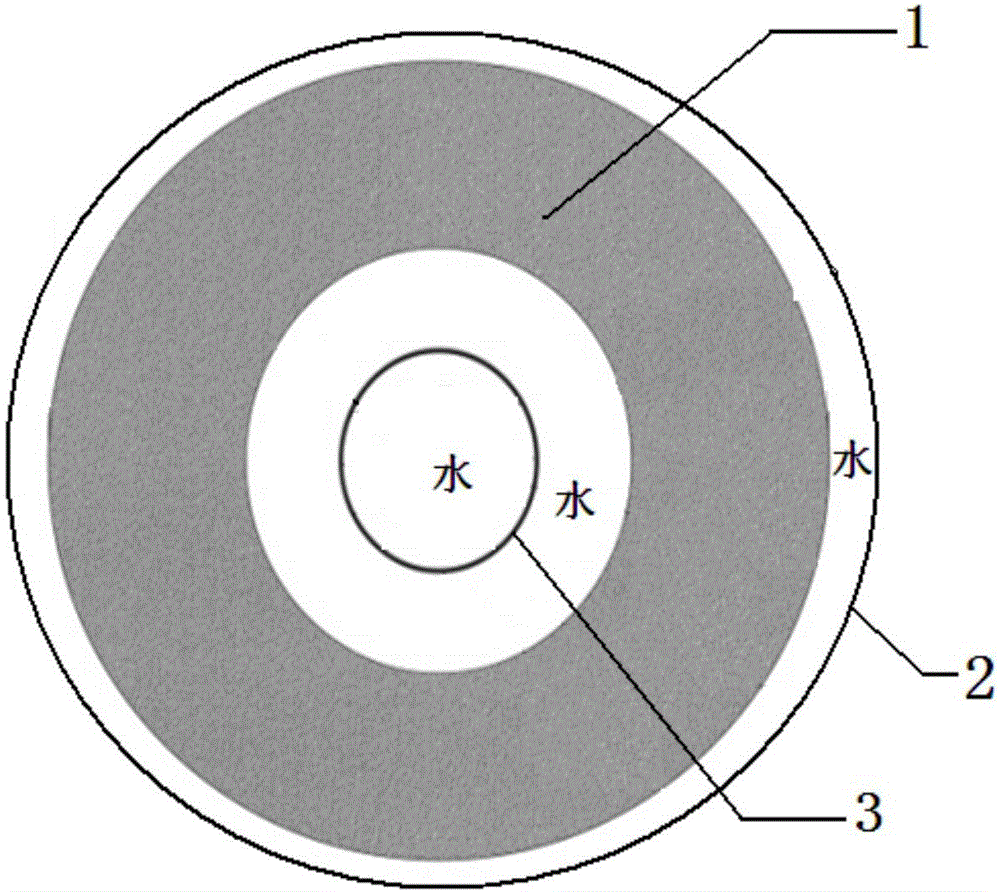

[0039] 1) A simulated formation 1 with a cylindrical structure with an open upper end and a closed lower end is produced, with a height of 1200 mm, an outer diameter of φ500 mm, and an inner diameter of φ215.9 mm.

[0040] 2) Place the prepared simulated formation 1 in the bucket 2 .

[0041] 3) Use a crane to put the casing 3 not coated with the drilling fluid layer 5 into the simulated formation 1. The outer diameter of the casing 3 is φ139.7mm, the inner diameter is φ127.6mm, and the length is 1200mm. The inserted casing 3 has a coaxial relationship with the simulated formation 1 .

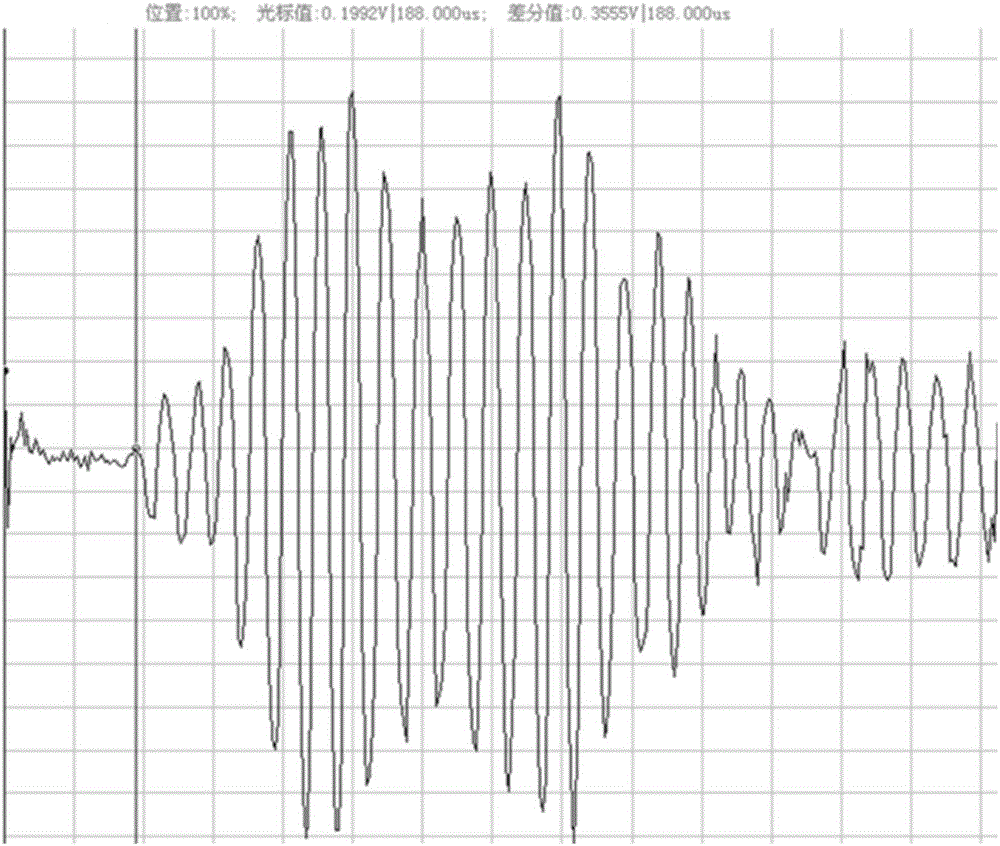

[0042] 4) An ultrasonic probe 7 is fixed in the center of the casing 3 through the fixed cover 6, and the ultrasonic probe 7 is electrically connected to an external oscilloscope, a pulse generator receiver and a high-speed transient signal acquisition instrument.

[0043] 5) Water is injected into the barrel 2, the height o...

Embodiment 2

[0049] 2. When the casing 3 is only cemented with the cement sheath 4, the implementation process is as follows:

[0050] 1) A simulated formation 1 with a cylindrical structure with an open upper end and a closed lower end is produced, with a height of 1200 mm, an outer diameter of φ500 mm, and an inner diameter of φ215.9 mm.

[0051] 2) Place the prepared simulated formation 1 in the bucket 2 .

[0052] 3) Use a crane to put the casing 3 not coated with the drilling fluid layer 5 into the simulated formation 1. The outer diameter of the casing 3 is φ139.7mm, the inner diameter is φ127.6mm, and the length is 1200mm. The inserted casing 3 has a coaxial relationship with the simulated formation 1 .

[0053] 4) An ultrasonic probe 7 is fixed in the center of the casing 3 through the fixed cover 6, and the ultrasonic probe 7 is electrically connected to an external oscilloscope, a pulse generator receiver and a high-speed transient signal acquisition instrument.

[0054] 5) Wat...

Embodiment 3

[0060] 3. The cement sheath 4 is well cemented with the casing 3 and the simulated formation 1. The process is as follows:

[0061] 1) A simulated formation 1 with a cylindrical structure with an open upper end and a closed lower end is produced, with a height of 1200 mm, an outer diameter of φ500 mm, and an inner diameter of φ215.9 mm.

[0062] 2) Place the prepared simulated formation 1 in the bucket 2 .

[0063] 3) Put the casing 3 coated with the drilling fluid layer 5 into the simulated formation 1 by a crane. The outer diameter of the casing 3 is φ139.7mm, the inner diameter is φ127.6mm, and the length is 1200mm. The inserted casing 3 has a coaxial relationship with the simulated formation 1 .

[0064] 4) An ultrasonic probe 7 is fixed in the center of the casing 3 through the fixed cover 6, and the ultrasonic probe 7 is electrically connected to an external oscilloscope, a pulse generator receiver and a high-speed transient signal acquisition instrument.

[0065] 5) W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com