A kind of processing method of gear texture surface

A technology of textured surface and processing method, applied in the direction of elements with teeth, belts/chains/gears, gear teeth, etc., can solve problems such as analysis and evaluation of the lubrication state of the textured surface of gears not involved, and prolong the actual service life. , energy saving, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to clearly illustrate the technical characteristics of this patent, the following describes this patent in detail through specific implementation methods and in conjunction with the accompanying drawings.

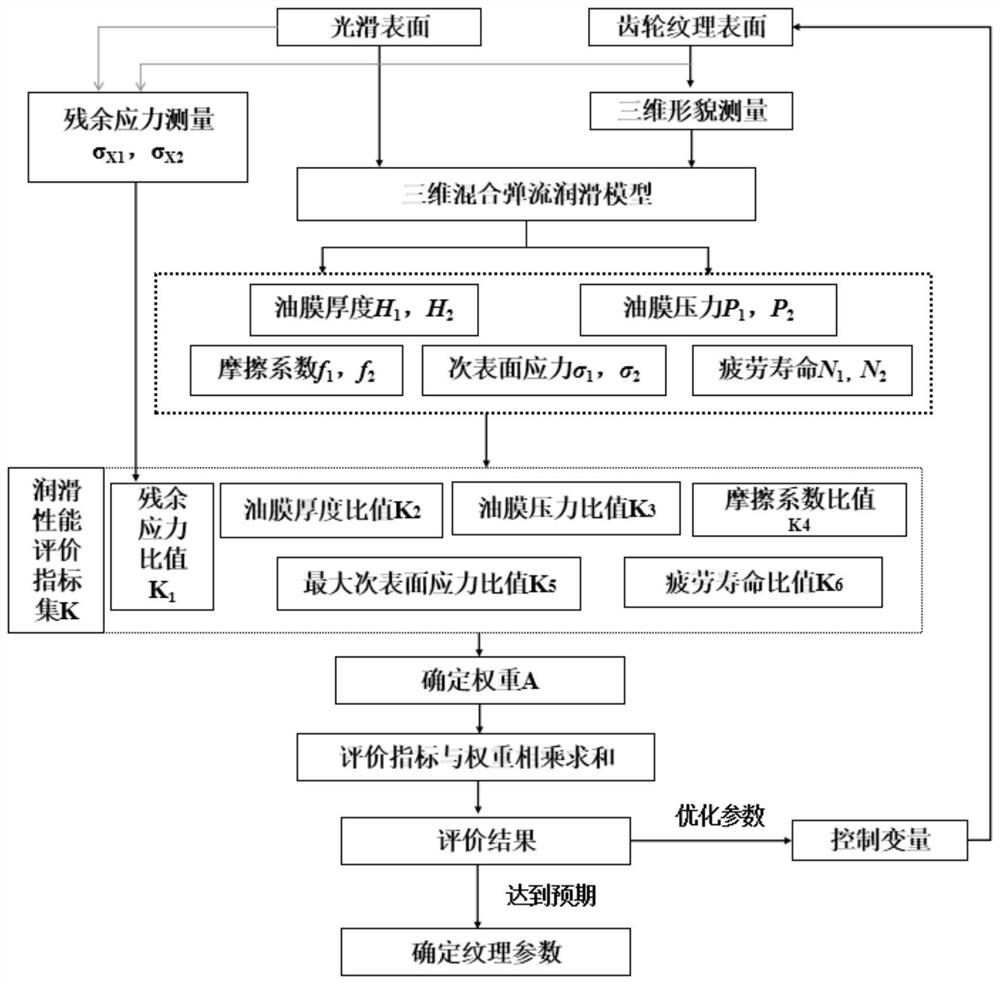

[0040] The present invention as figure 1 As shown in -5, process according to the following steps:

[0041] S1. Sampling:

[0042] S1.1. First take a smooth tooth surface as a smooth surface;

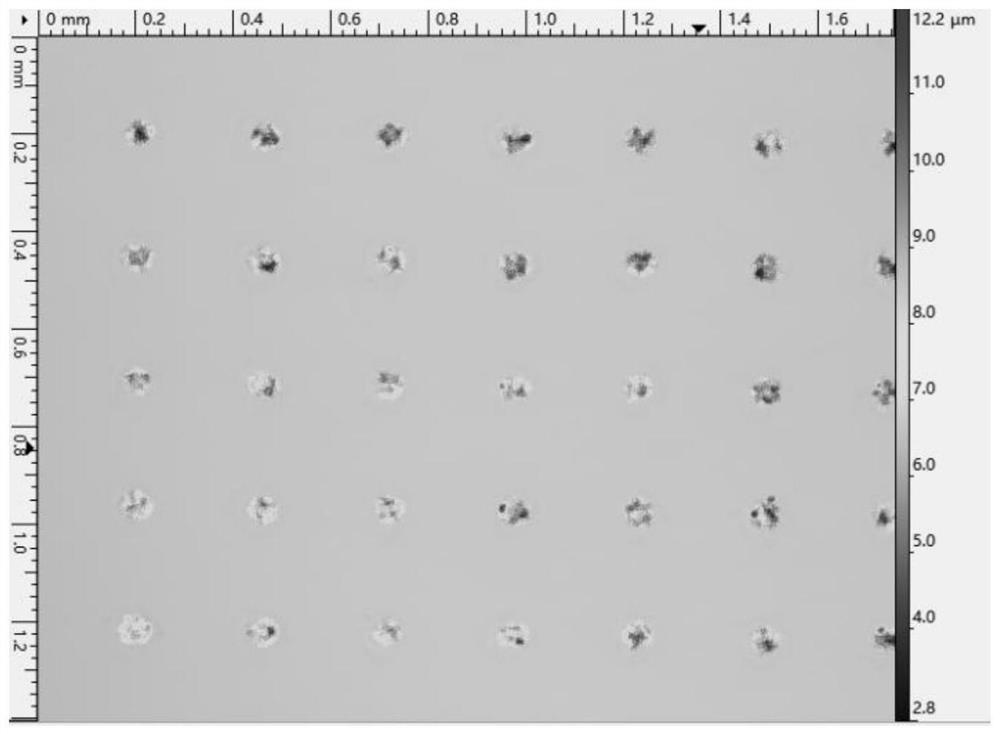

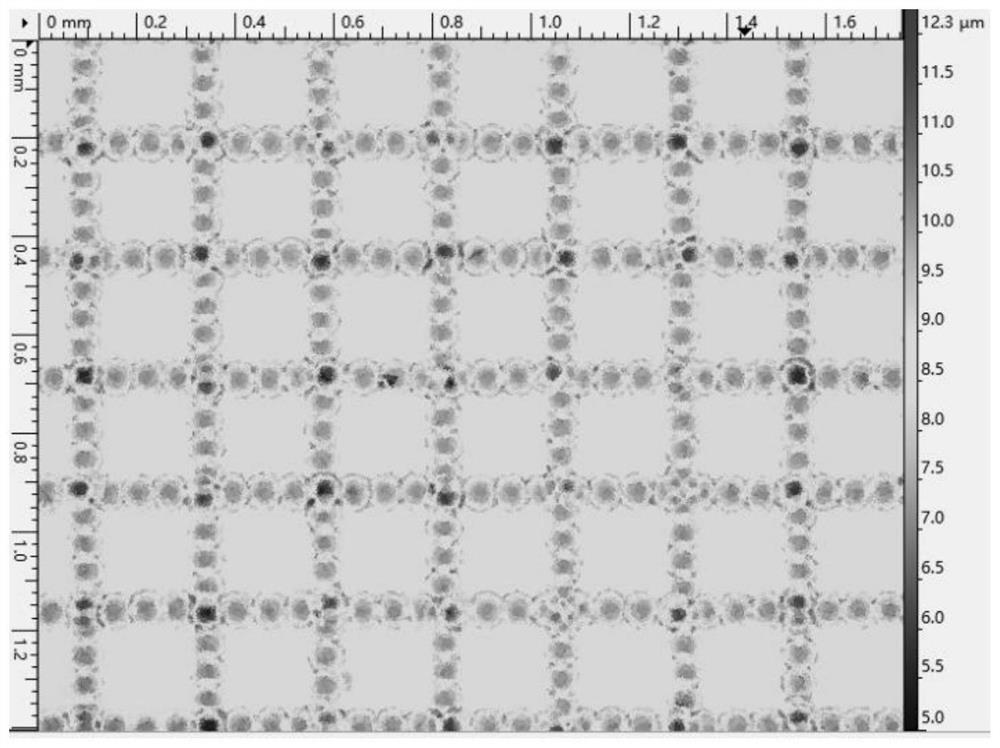

[0043] S1.2, take another smooth tooth surface, and use laser or electrochemical method to process a plurality of micropits or groove textures with a certain width, depth and area ratio on the smooth tooth surface to form a gear texture surface;

[0044] S2, data collection;

[0045] S2.1. Residual stress measurement: Obtain the tooth surface residual stress on the smooth surface and the gear texture surface respectively through the residual stress tester; and calculate the residual stress ratio between the smooth surface and the gear texture surface in the comput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com